Integrative construction device and method for pile cap and pile body of pouring pile

A construction device and cast-in-place pile technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of large investment in manpower, materials and mechanical equipment, increased dust, noise, slow project progress, etc., and achieve high economic benefits. and social and environmental benefits, reducing noise, and controlling construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

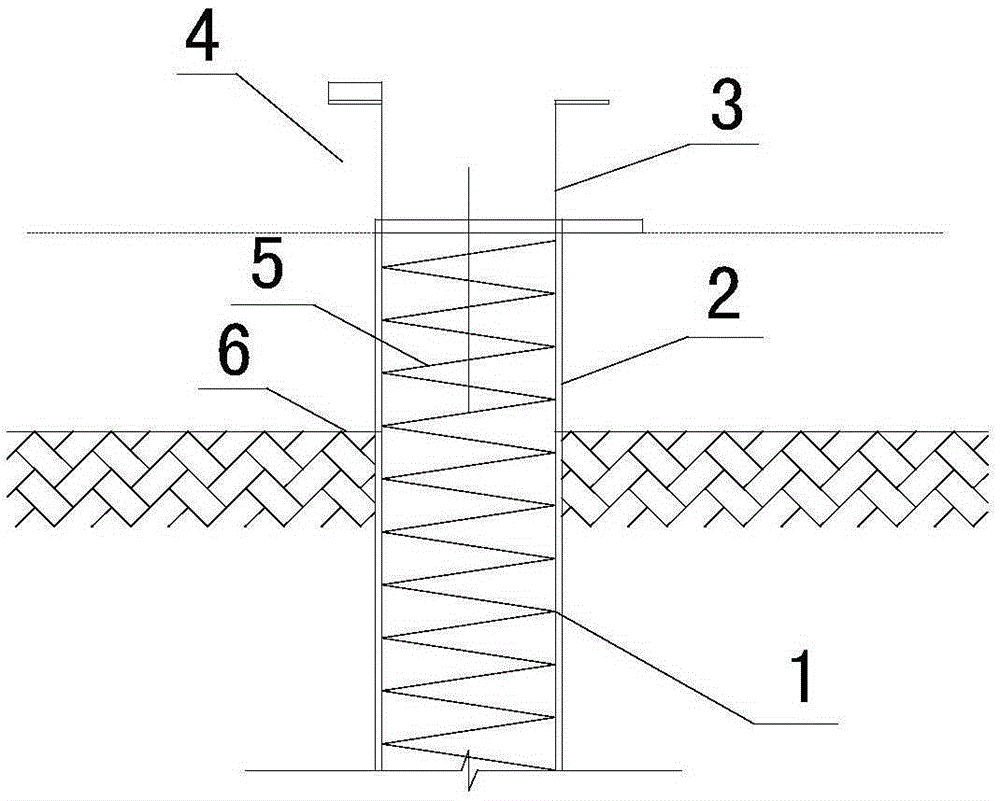

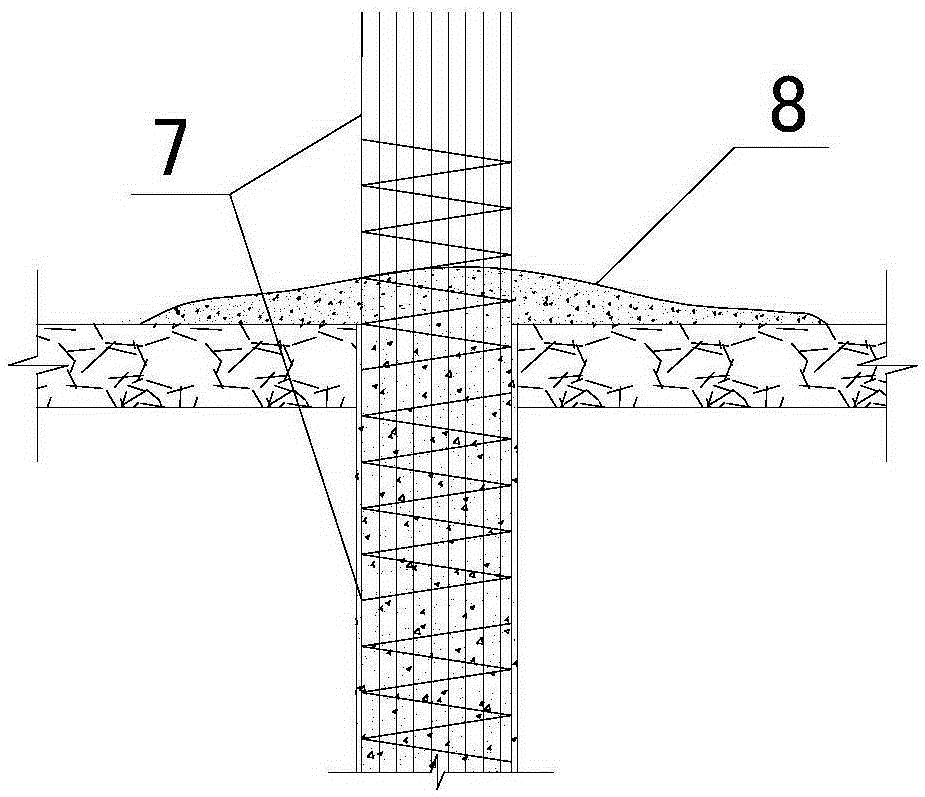

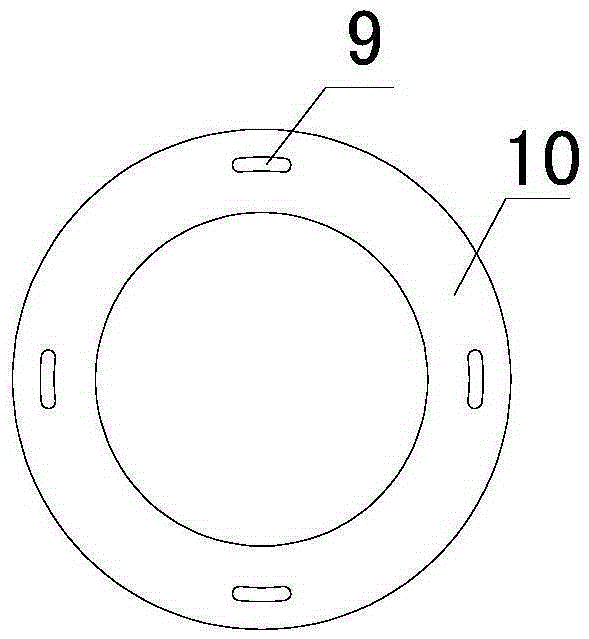

[0042] The cast-in-place pile cap and pile integrated construction device of this embodiment includes a level, a total station, and a steel backing plate 10 with an annular cross section. The annular steel backing plate 10 is laid around the upper port of the pile hole and is sleeved on On the overall reinforcement cage 7, the overall reinforcement cage 7 is installed in the pile hole, and the pile hole and the overall reinforcement cage 7 are axially coincident, and the overall reinforcement cage 7 is divided into two parts: the pile cap reinforcement 2 on the ground and the pile foundation underground part reinforcement 1. Reinforcement cage 7 comprises a group of longitudinally parallel main bars 3 and a helical stirrup 5 bounded on the group of main bars 3; the inner diameter of annular steel backing plate 10 is 1.2m, the outer diameter is 1.5m, and the thickness is 2cm. Be shaped on four slotted holes 9 on the steel backing plate 10 (see image 3 ), cooperate with slotted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com