Accurate positioning and producing device for intermittent joints of similar-material rock mass samples

A technology of precise positioning and similar materials, applied in the preparation of test samples, etc., can solve problems such as theoretical analysis deviation, material waste, gap form and setting parameter differences, and achieve simple operation, exquisite design, and enhanced system stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

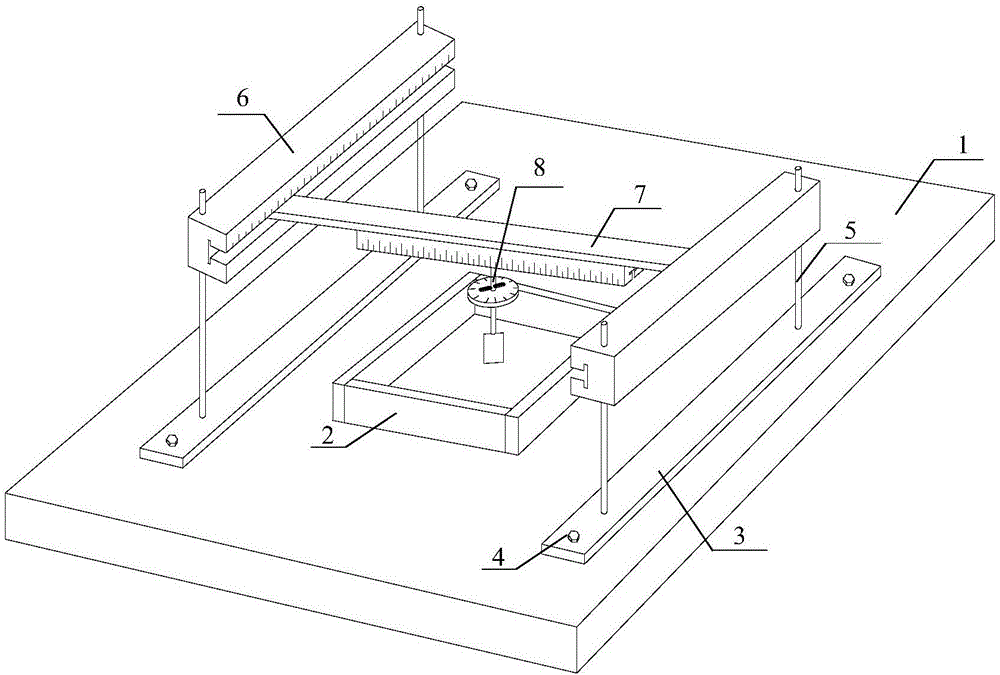

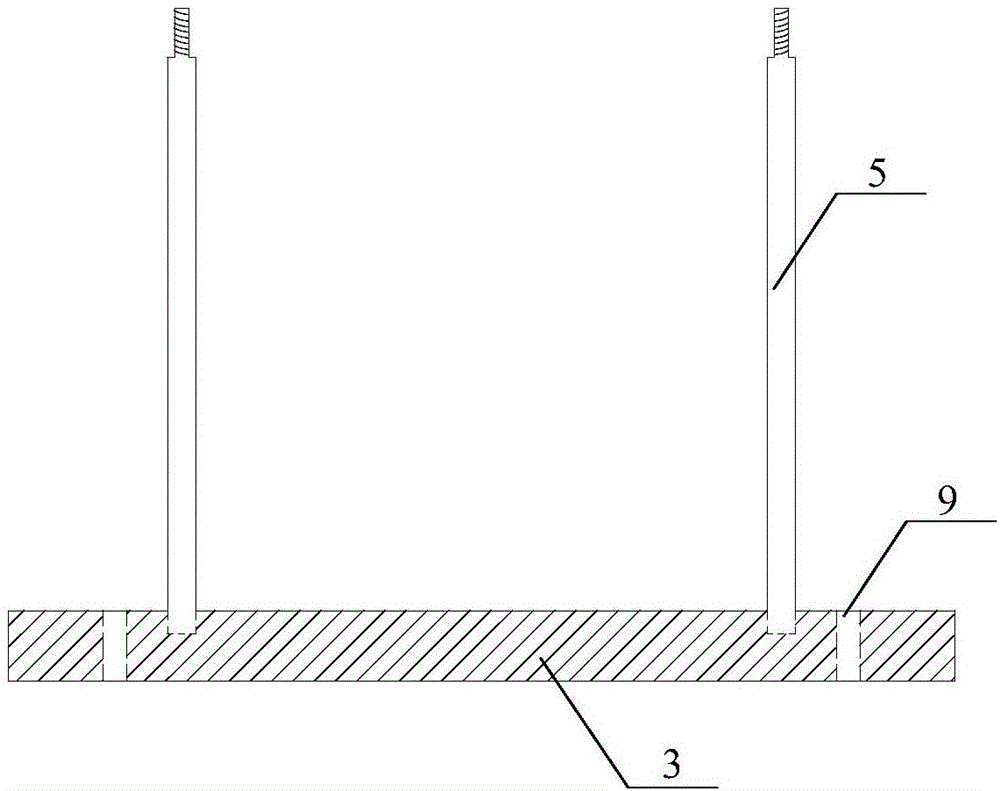

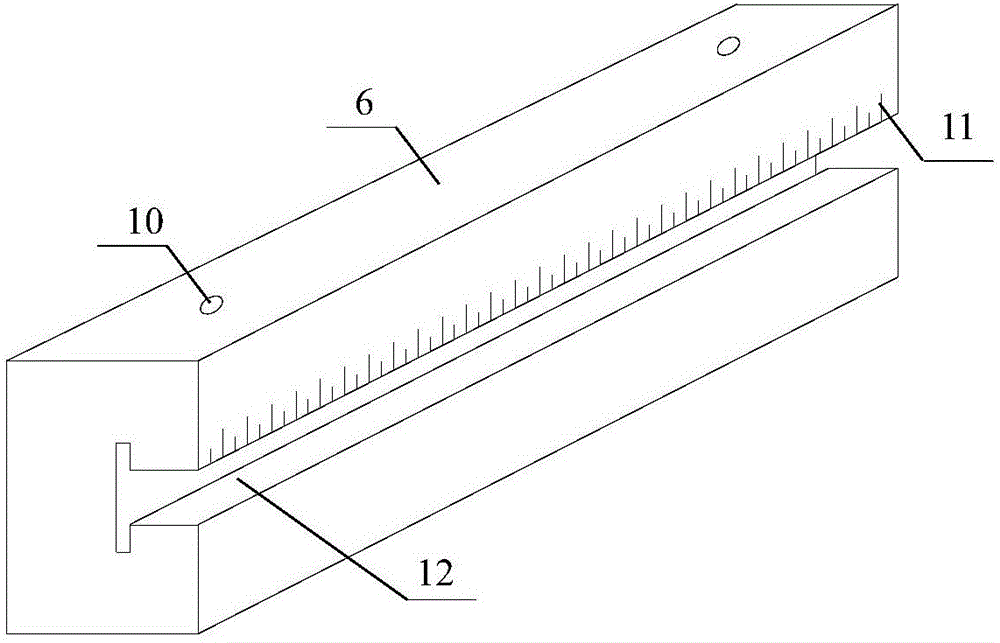

[0025] The invention relates to a device for precisely positioning intermittent joints of similar material rock mass samples. It consists of a sample preparation base plate 1, a sample mold 2, a fissure positioning support base plate 3, a fissure positioning support anchor bolt 4, a fissure positioning support rod 5, a fissure longitudinal positioning rod 6, a fissure transverse positioning rod 7, a fissure angle positioning device 8, and a fissure positioning rod. Positioning bracket anchor hole 9, crack longitudinal positioning rod anchor hole 10, crack longitudinal positioning scale 11, T-shaped through groove 12, lateral positioning rod slider 13, crack angle positioning chute 14, crack angle positioning slider 15, angle pointer 16. Angle dial 17, telescopic rod 18, steel sheet 19, and angle scale 20 form. Such as figure 1As shown, the connection relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com