Drilling pile casing guide device provided with calibration mechanisms and control method

A technology for calibrating mechanisms and guiding devices, which is applied in the direction of infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of low efficiency, inability to guarantee the verticality of drilling casings, poor stability, etc., and achieve good safety and construction efficiency High and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

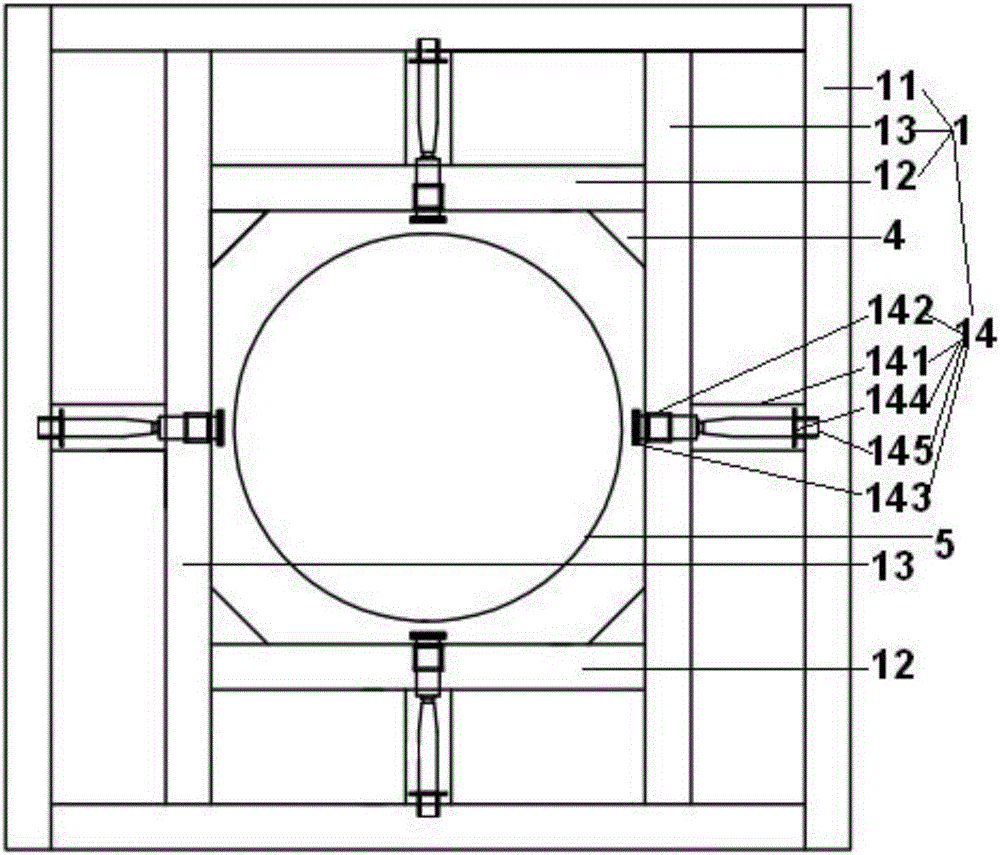

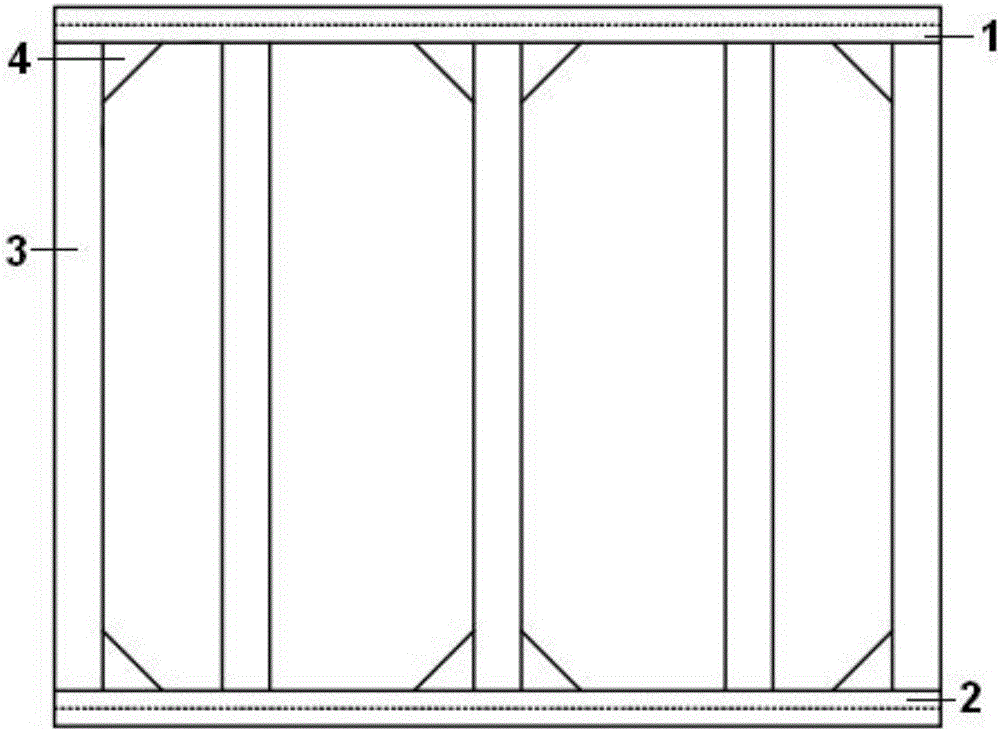

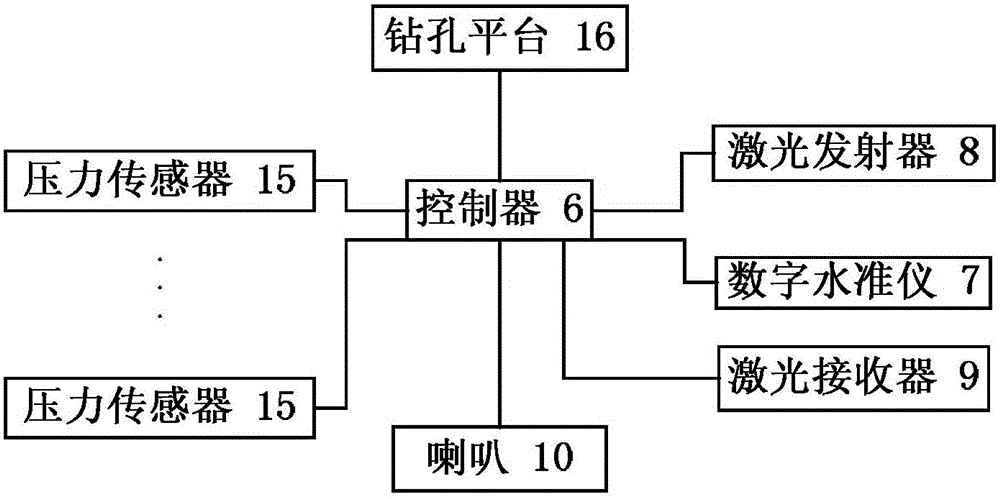

[0039] Such as figure 1 , figure 2 The illustrated embodiment is a drilling casing guide device provided with a calibration mechanism, including an upper bracket 1, a lower bracket 2, 12 support columns 3 arranged between the upper bracket and the lower bracket, a controller 6, and a digital Level 7, laser transmitter 8, laser receiver 9 and loudspeaker 10; The upper support includes a rectangular frame 11, two transverse bars 12 arranged in the rectangular frame, and two longitudinal bars 13 connected to the two ends of the two transverse bars respectively , the vertical calibration mechanism 14 that is located on the frame corresponding to the horizontal bar of each horizontal bar and the rectangular frame, and the 2 horizontal calibration mechanisms that are located on each vertical bar and the rectangular frame; as image 3As shown, the controller is electrically connected with the digital level, the laser transmitter, the laser receiver and the horn respectively, and th...

Embodiment 2

[0057] Embodiment 2 includes all methods and structural parts of embodiment 1, such as figure 1 As shown, each horizontal calibration mechanism and vertical calibration mechanism of Embodiment 2 all include a guide cylinder 141, a roller bracket 142 located at the front of the guide cylinder, a roller 143 located on the rotating shaft of the roller bracket, and a roller 143 located at the rear of the guide cylinder. The limiting plate 144 and the screw rod 145 located on the limiting plate; the roller bracket rear portion is provided with a sleeve, the front end of the screw is provided with an annular groove, and the annular edge located at the rear portion of the sleeve is embedded in the annular groove, and the annular The edge is slidingly connected with the annular groove, and the screw rod is threadedly connected with the limit plate; the drilling casing is provided with such as corresponding to each roller image 3 The pressure sensors 15 shown are each electrically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com