N00 mining method adopting mode of top cutting for filling

A mining method and top-cutting technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve problems such as surface gangue accumulation, poor stope structure stability, surface subsidence and deformation, etc., so as to reduce support strength and reduce coal mine economics. Pressure, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention. Unless otherwise specified, the terms used in the present invention are conventional terms in the industry.

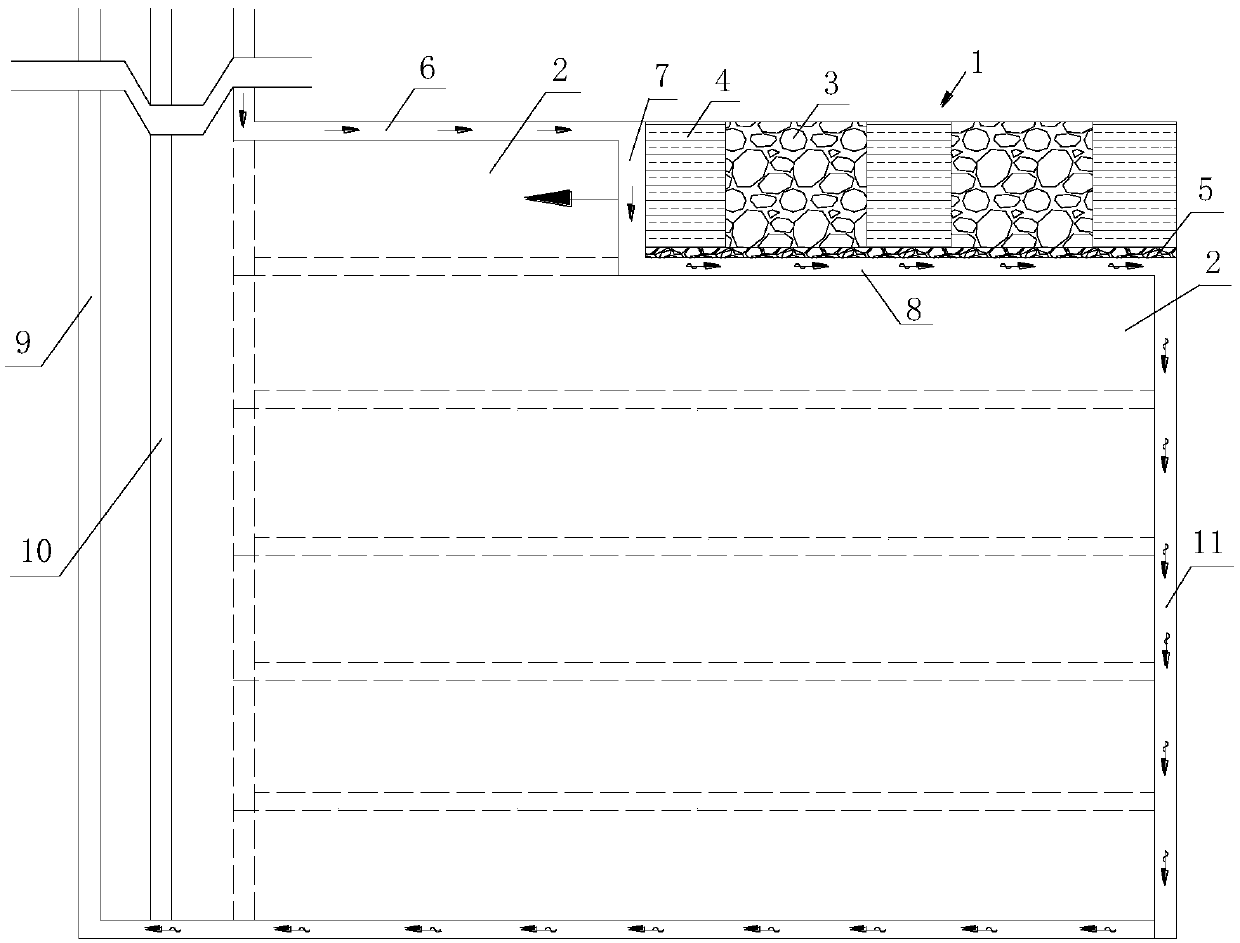

[0030] Such as figure 1 As shown, the present invention provides a top cutting and filling N00 mining method, in which a plurality of working faces 2 are set in a new panel 1, so as to realize a kind of roadway-free excavation and mining without coal pillars. On one side of the entire panel 1, there is a return air downhill passage 9 and a track downhill passage 10, and a belt downhill passage 11 is provided from the wellhead of the panel 1 to the other side of the panel 1, and the belt downhill passage 11 surrounds the entire panel After 1, it is connected with the return air downhill passage 9, and the return air downhill passage 9, the track downhill passage 10, and the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com