Advance support method for coal mine tunnel high-risk area

A technology of advanced support and coal mine roadway, which is applied to tunnels, tunnel linings, temporary shields, etc., and can solve problems such as safety impact, roof fall, and construction difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution will be further described below with reference to the accompanying drawings.

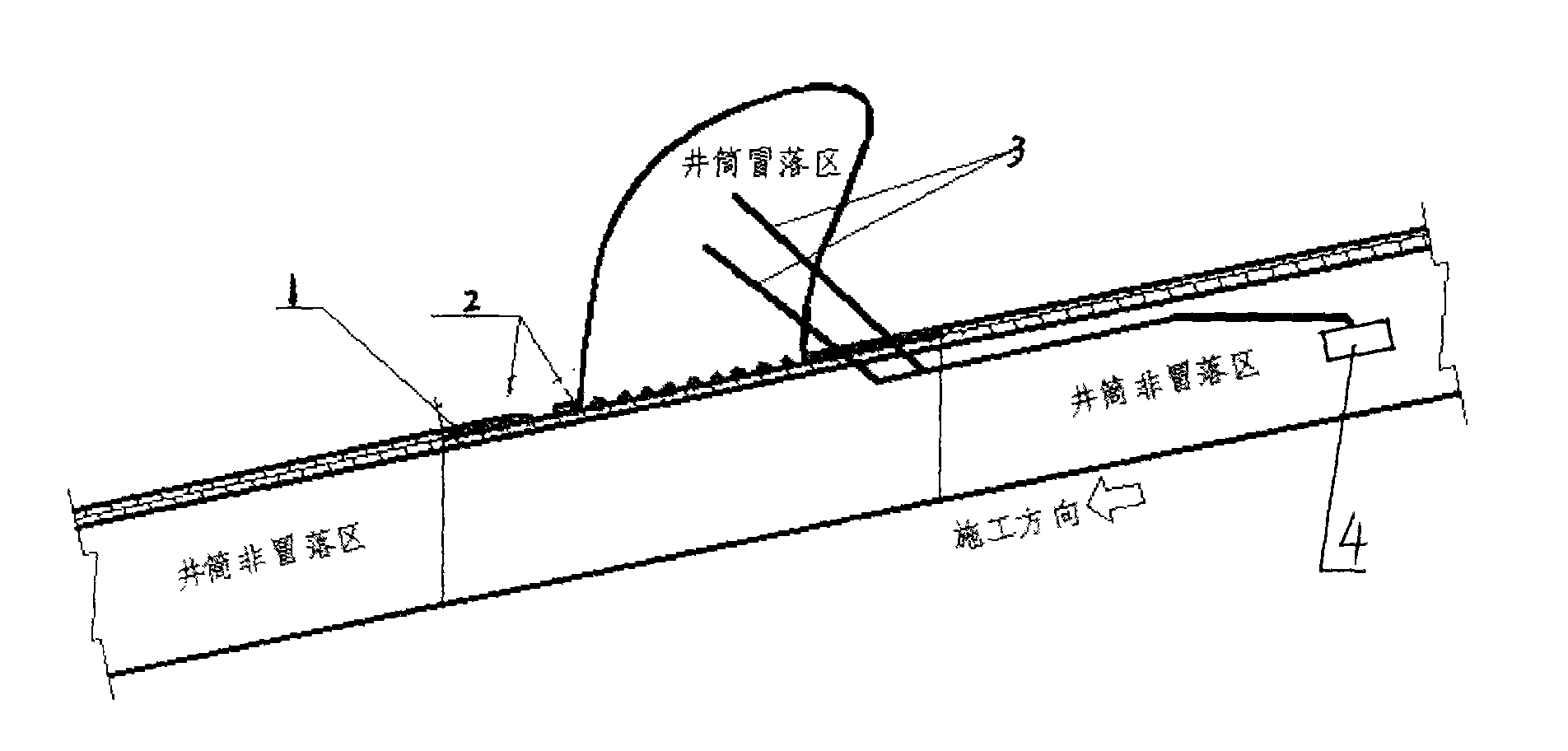

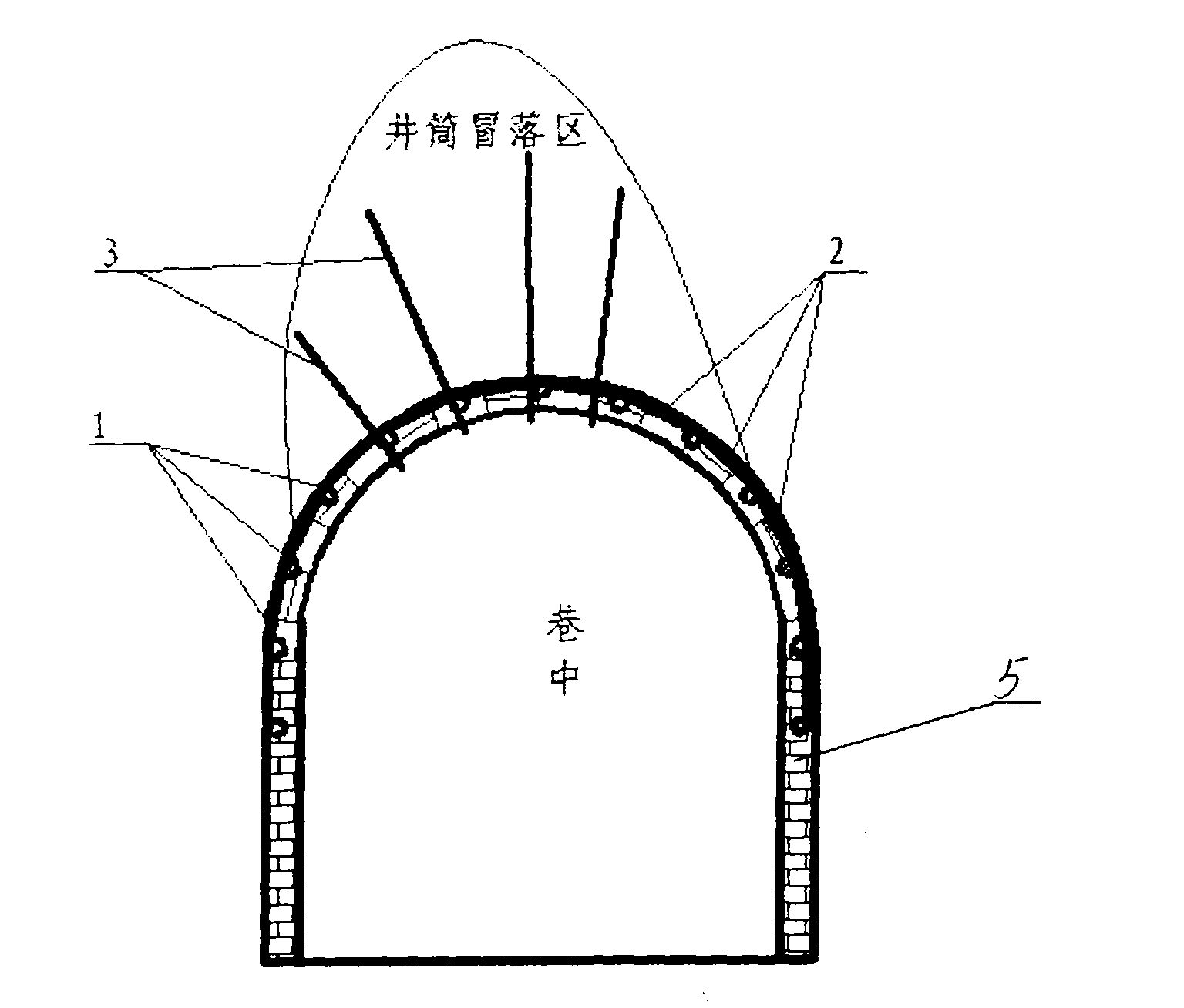

[0015] Such as figure 1 with figure 2 Shown, the supporting method of the present invention is as follows:

[0016] Step 1: In the excavation construction, first find out the scope of the roadway caving area, such as length, width and height, by means of drilling ahead, and then draw a map of the distribution range of the roadway caving area;

[0017] Step 2: Use a special drilling rig to construct and drill holes along the roadway contour line to the direction of excavation. The drill hole passes through the detected caving area or cavity area beyond 5 meters, and the drill pipe 1 is left in the borehole as a roadway excavation. temporary support;

[0018] Step 3: After each excavation cycle, use the waste drill pipe 2 to overlap the drill pipe 1 close to the wall of the roadway, and fix it with iron wire to become a temporary support roof;

[0019] Step 4: Under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com