Foam blocks for construction of mine tunnel stoppings

a technology of mine tunnels and blocks, which is applied in the direction of shaft equipment, shaft linings, surface mining, etc., can solve the problems of air leakage, difficult construction of walls, and very laborious construction, and achieves little or no practical success

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

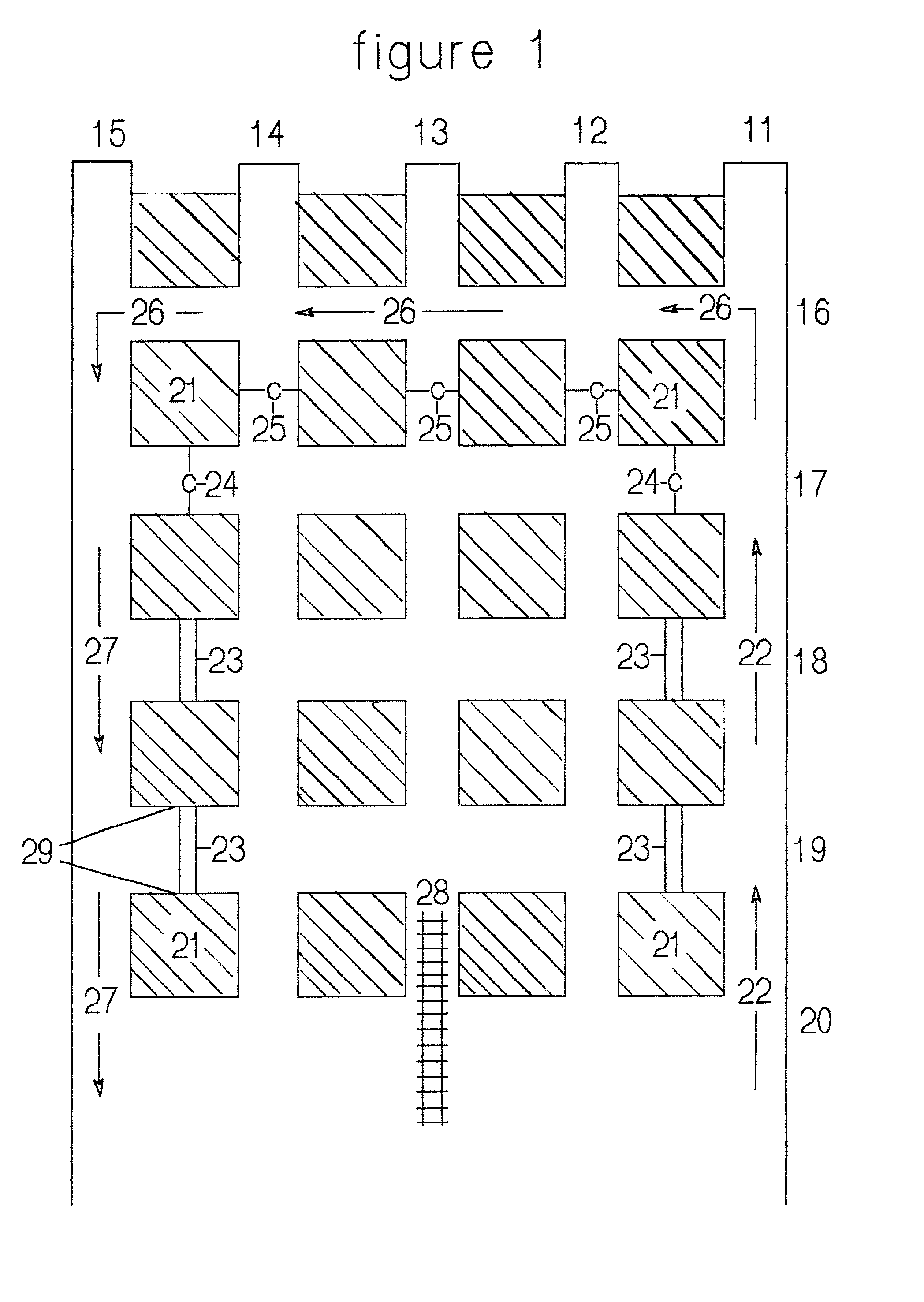

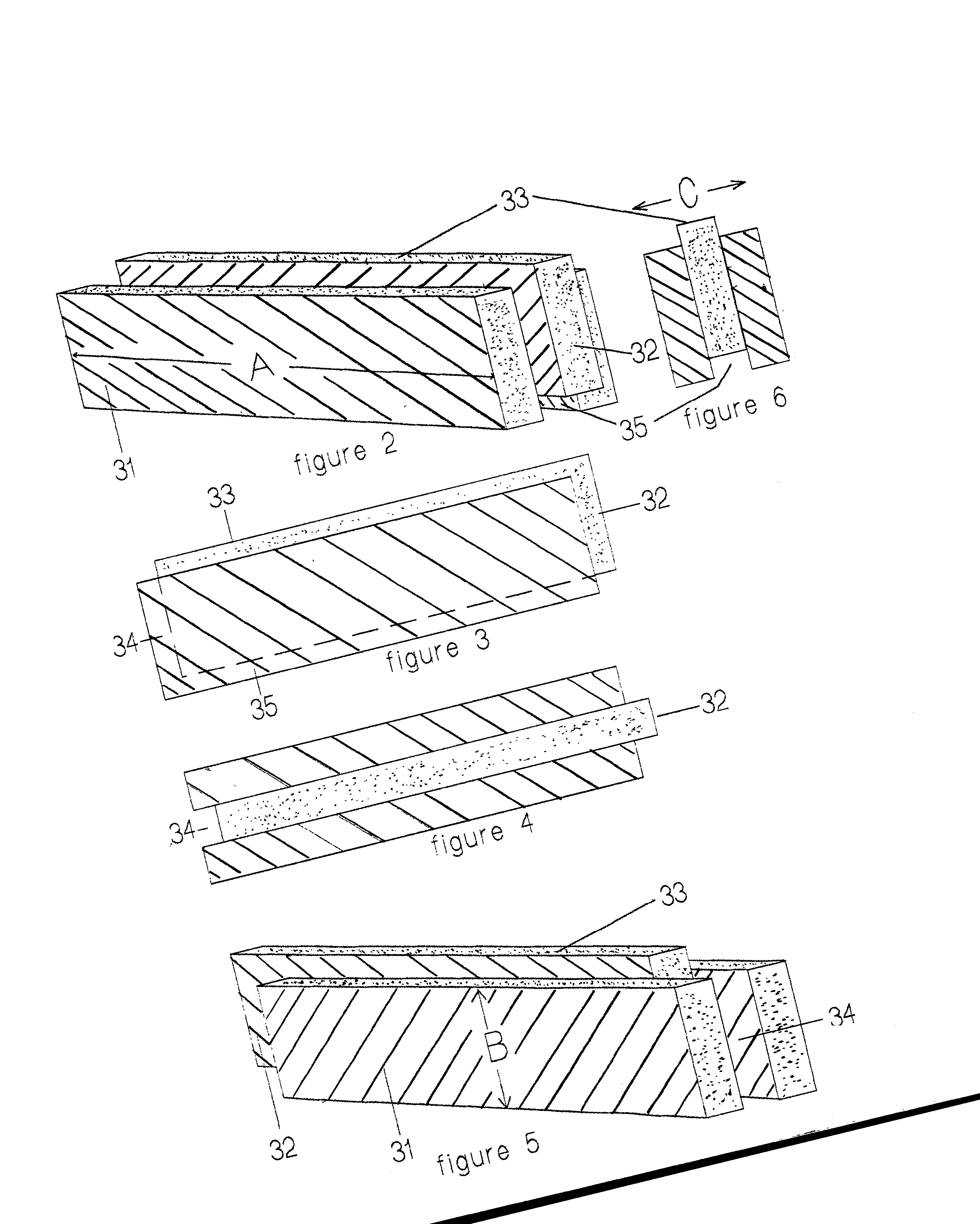

[0055] In describing this embodiment of the invention specific terminology and dimensions will be used for the sake of clarity and comparison to prior art. However, the invention is not intended to be limited to these specific terms or dimensions, and it is to be understood that each specific term includes all technical equivalents which operate in a similar manner to accomplish a similar purpose.

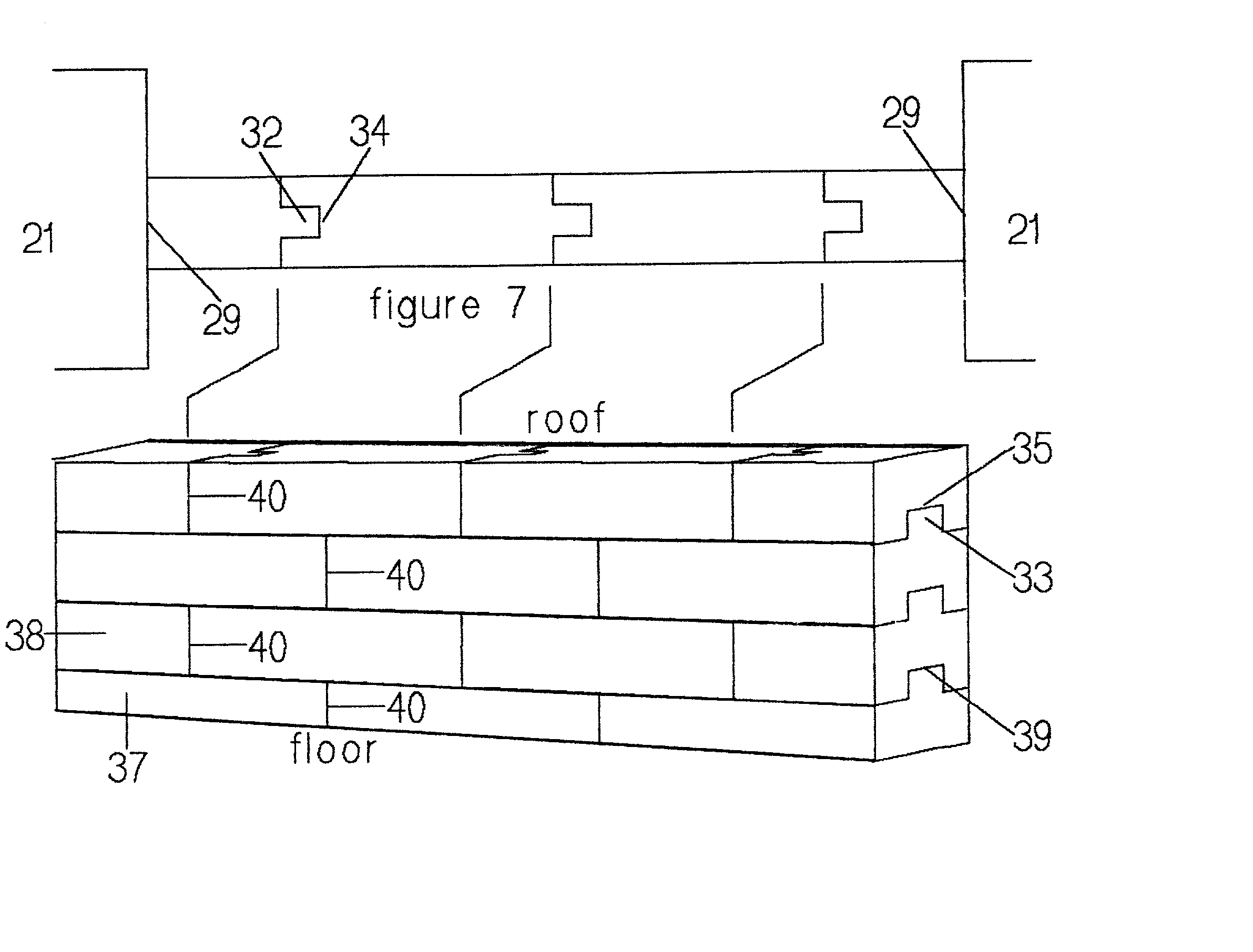

[0056] To facilitate understanding of the environment in which mine stoppings are used, and air flow patterns are created, it is believed the following discussion of FIG. 1 will be helpful.

[0057] In FIG. 1 a plurality of mine tunnels or "headings" are represented by numbers 11-12-13-14-15. The area at these numbers 11 thru 15 will constitute the working face of the mine. Extending perpindicular to and intersecting columns 11 thru 15 are tunnels represented by rows 16-17-18-19-20. These rows are generally referred to as "crosscuts". These columns and rows together form a plurality of Pillars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com