Loose broken tunnel top plate reinforcing and supporting method

A roadway roof, soft technology, applied in tunnels, tunnel linings, earthwork drilling and other directions, can solve the problems of difficult coal roadway support, roof collapse, easy weathering and breaking, etc., to improve local stability, improve overall performance, avoid The effect of local buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

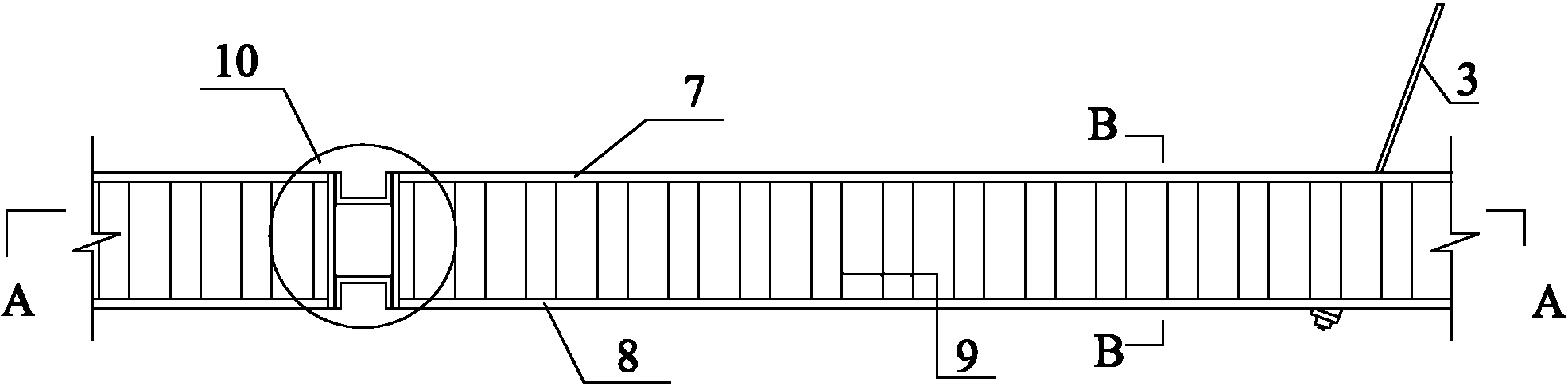

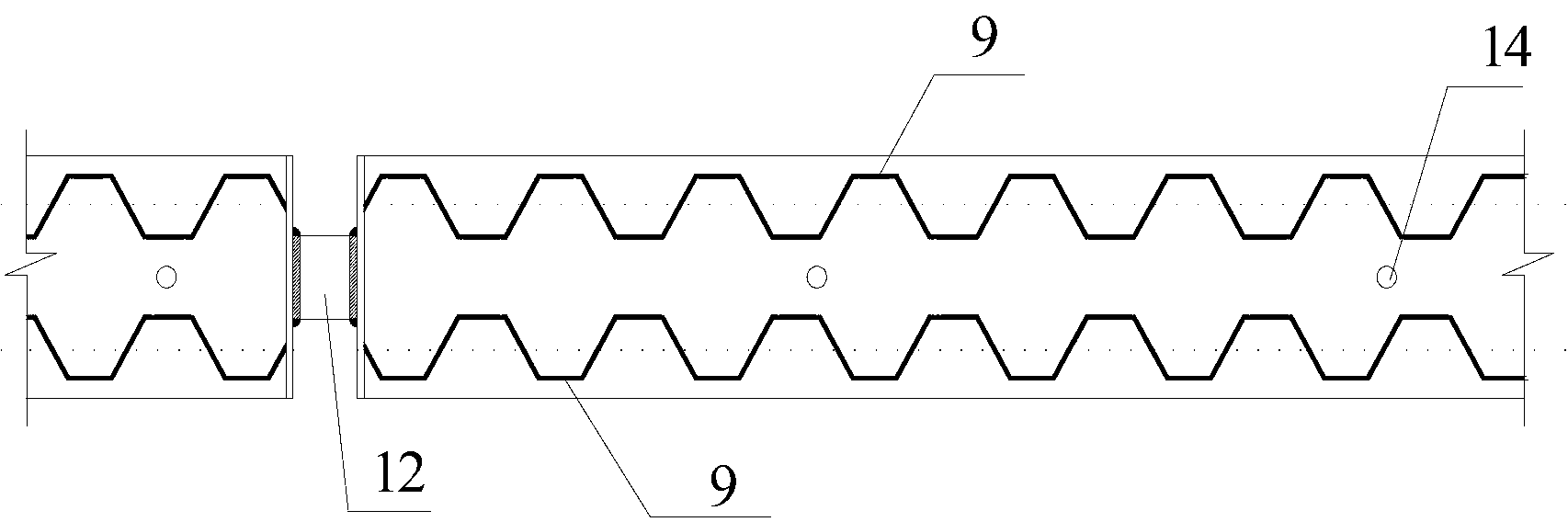

[0029] The method of the present invention will be further described below in conjunction with the accompanying drawings.

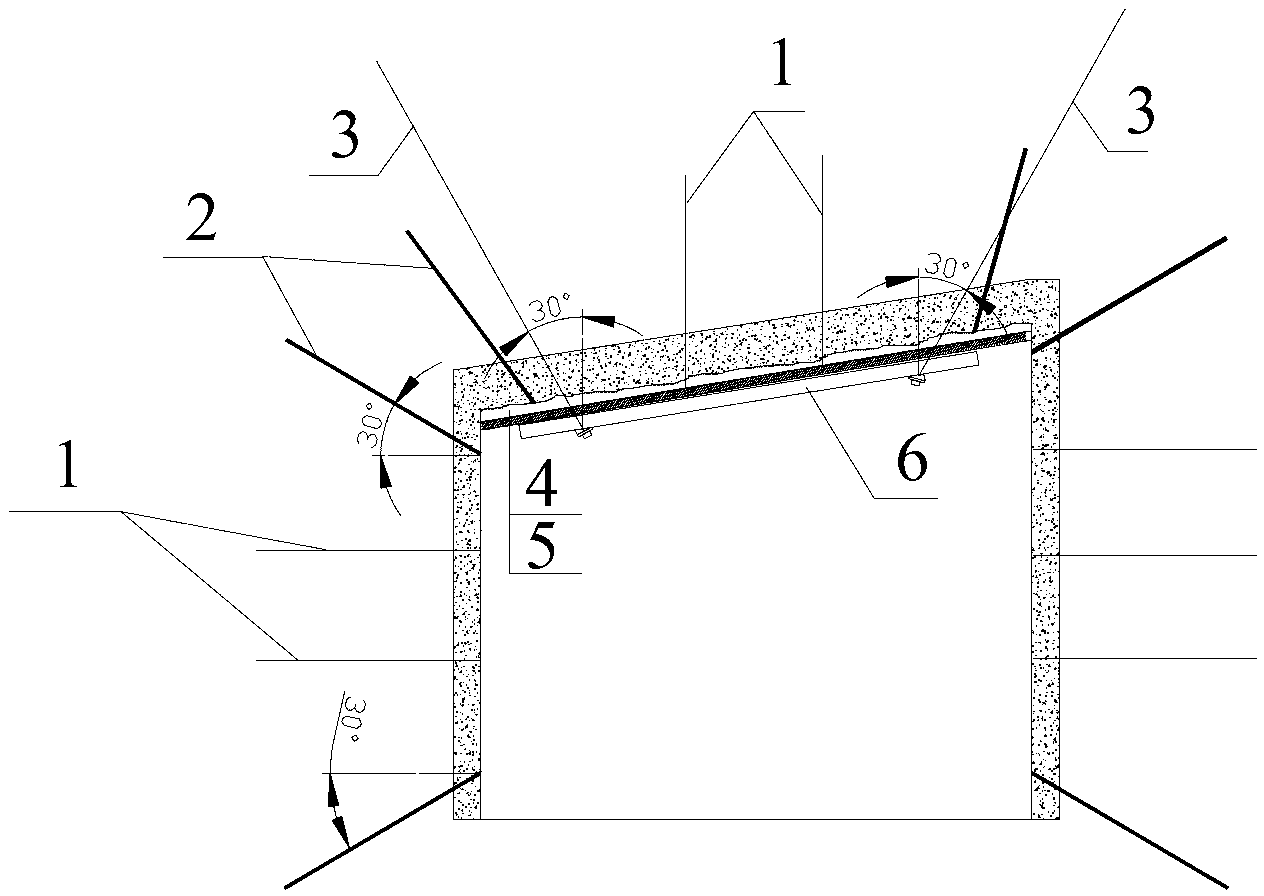

[0030] Such as figure 1 As shown, the method of the present invention is applied to the reinforcement and support of the roof of the soft and broken surrounding rock roadway. The method can effectively control the sinking amount of the roof and reduce the occurrence of roof fall accidents.

[0031] A. Excavate the roadway, remove the dangerous rocks on the surface of the roadway, and seal the crack surface of the surrounding rock with shotcrete;

[0032] B. Carry out grouting bolt 2 construction. First, make grouting holes at 0.3-0.5 meters from the left and right side walls on the roof that is prone to collapse in the roadway, with an elevation angle of 45°; make grouting holes at the upper part of the left and right side walls at a distance of 0.3-0.5 meters from the roof, with an elevation angle of 30°; Make a grouting hole at the bottom of the left ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com