Narrow-machine-body full-hydraulic bolt and anchor cable drill carriage for coal mine tunnel

A coal mine roadway, full hydraulic technology, which is applied in the installation of bolts, drilling equipment, cutting machinery, etc. It is not suitable for problems such as the use of fully mechanized excavation working face, and achieves the effect of free and reliable walking, compact structure and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

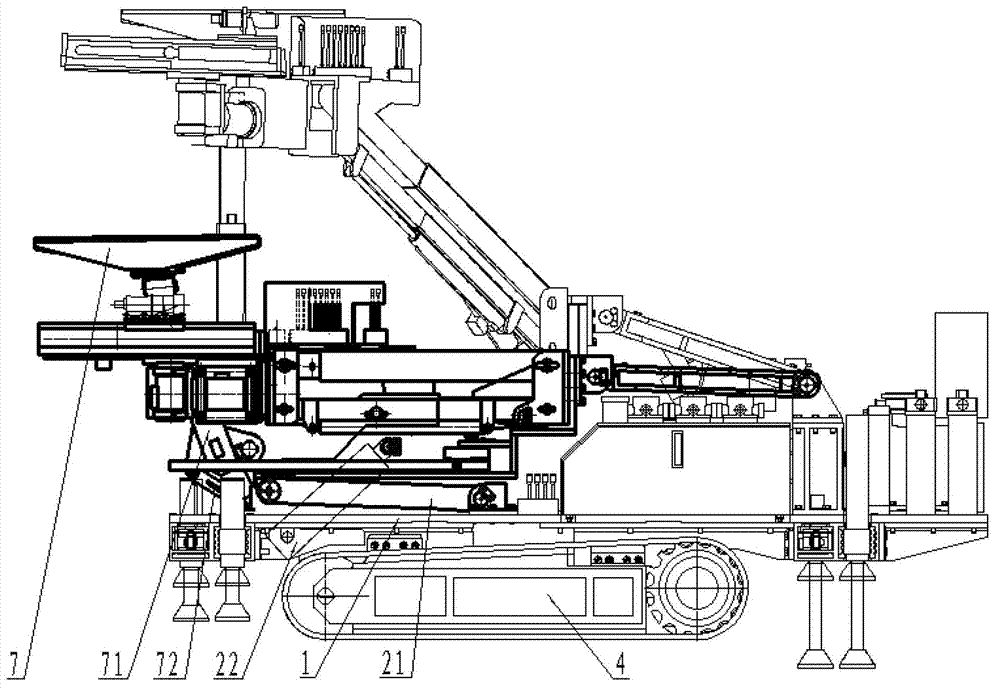

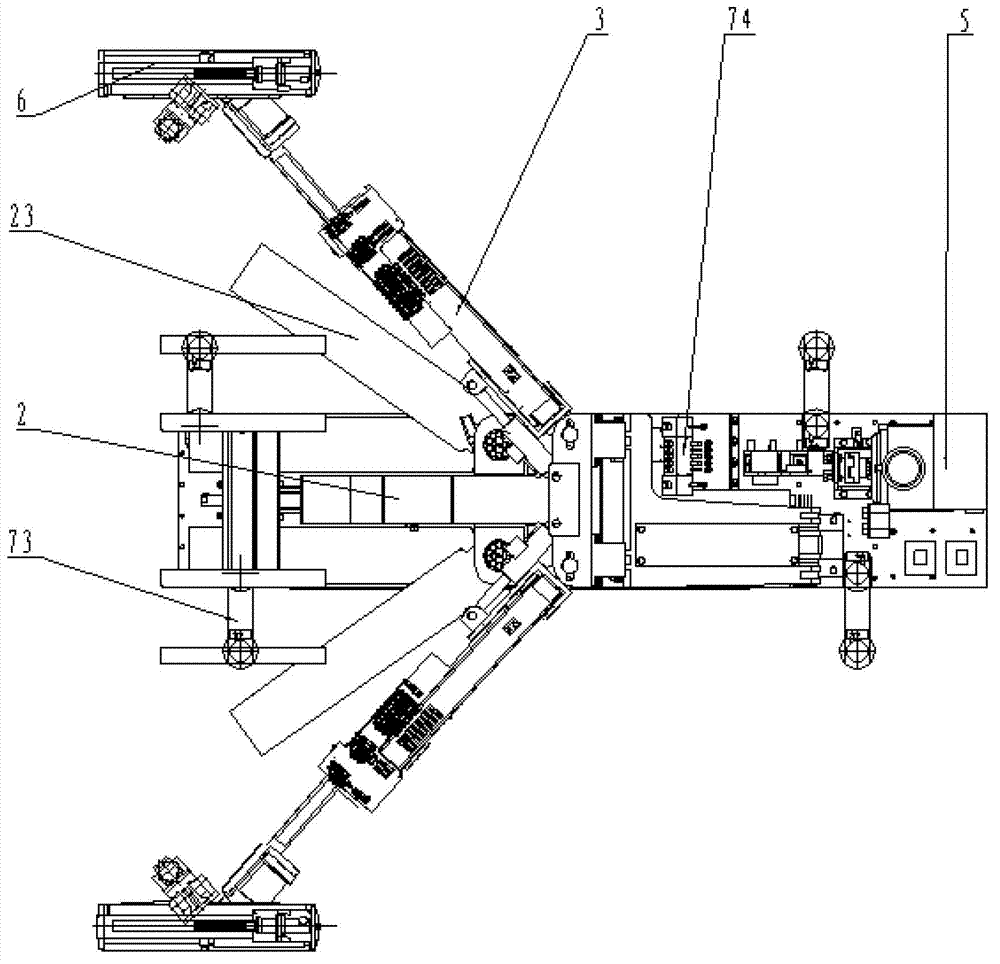

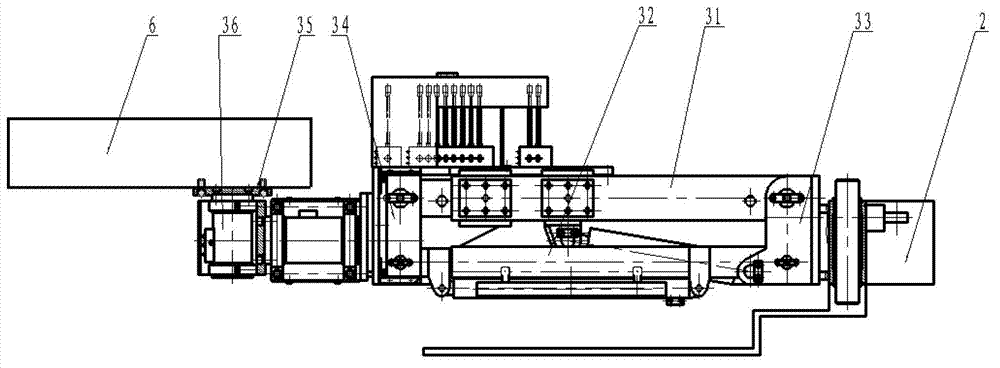

[0028] see figure 1 , figure 2 As shown, the present invention is a kind of narrow fuselage fully hydraulic anchor rod and cable anchor drilling rig for coal mine roadway, which mainly includes a body part 1, a lifting platform 2, a drilling boom mechanism 3, a crawler type traveling mechanism 4 and an electric control box 5.

[0029] Wherein, the lifting platform 2 is installed on the body part 1 through a folding connecting rod 21 and a lifting cylinder 22 . The lifting platform 2 can well meet the support requirements of different positions in the roadway. The lifting platform 2 is controlled by a folding connecting rod 21 and a lifting oil cylinder 22, which is easy to operate and stable in lifting.

[0030] Further, the lifting platform 2 of the present invention is also equipped with a front support mechanism 7, the front support mechanism 7 is installed in the middle position of the front part of the lifting platform 2, including a support square tube 71 rotatably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com