Safe and precise control of fast cooling and fast heating automatic switching temperature control system

A technology of automatic switching and temperature control system, applied in control/regulation system, temperature control, non-electric variable control and other directions, can solve the problems of continuous manual monitoring, difficult to meet customer production needs, low temperature control accuracy, etc. Pressure stability and internal safety, favorable for smooth circulation, and high system safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

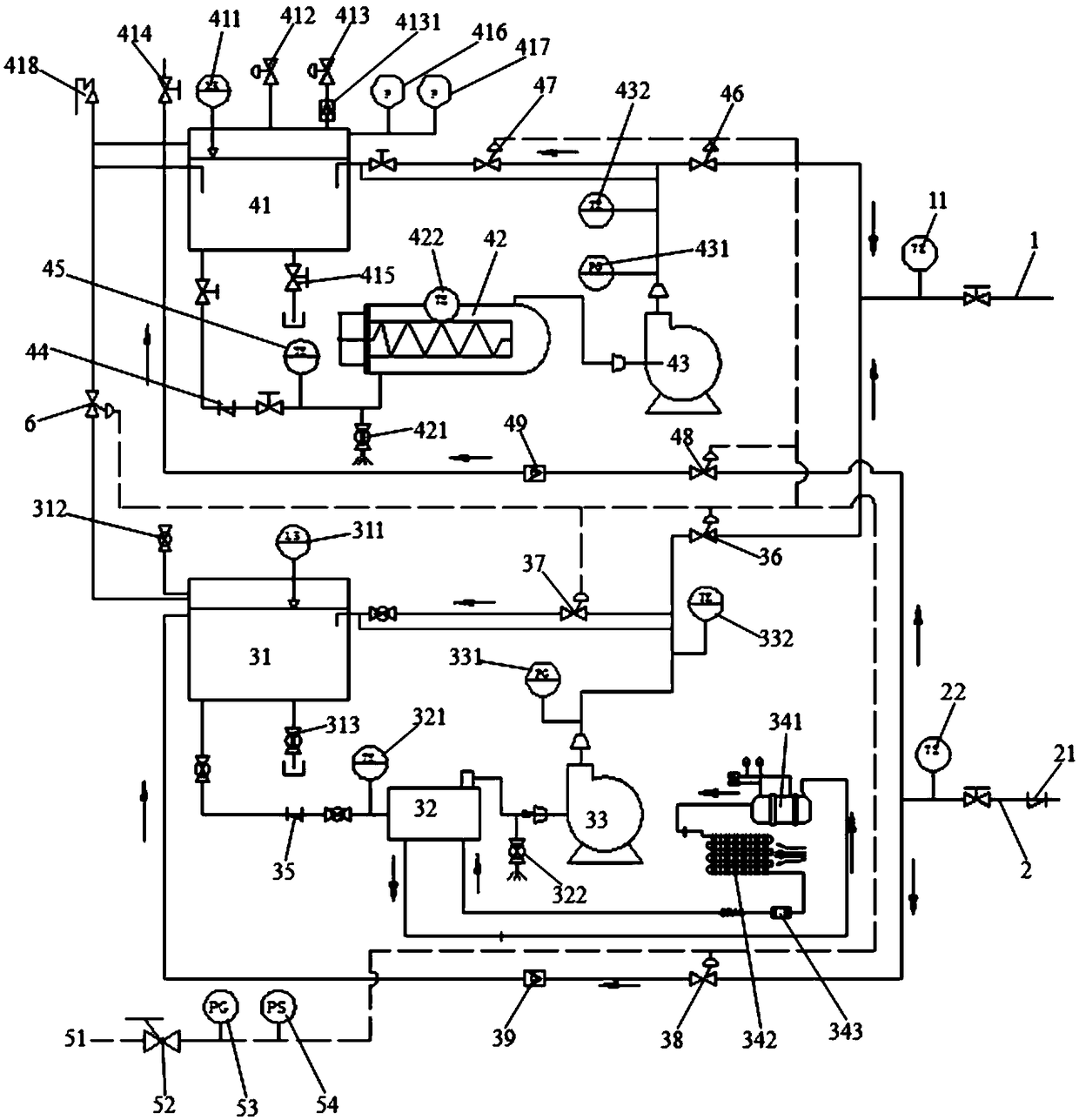

[0030] Please refer to figure 1 , this embodiment is a safe and precise controlled quick cooling and quick heating automatic switching temperature control system, which includes an oil outlet pipeline 1, an oil return pipeline 2, a cooling circulation system connected to the oil outlet pipeline 1 and the oil return pipeline 2, and The heating circulation system and the gas path system running through the cooling circulation system and the heating circulation system.

[0031] A first thermocouple 11 is arranged at the oil outlet pipeline 1 . The first thermocouple 11 is mainly used to detect the temperature of the heat transfer medium going out from the oil outlet pipeline 1 .

[0032] A first filter 21 and a second thermocouple 22 are arranged in sequence along the flow direction at the oil return pipeline 2 . The second thermocouple 22 mainly detects the temperature of the heat transfer medium entering from the oil return pipeline 2 .

[0033] The cooling circulation syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com