Compressed air heat energy recovery and control system

A technology of compressed air and control system, applied in pump control, liquid variable volume machinery, variable volume pump components, etc., can solve the lack of comprehensive control, inability to compress air regulation control, lack of safety and convenience of use, etc. problems, to achieve stable work, ensure automatic operation, and facilitate use and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

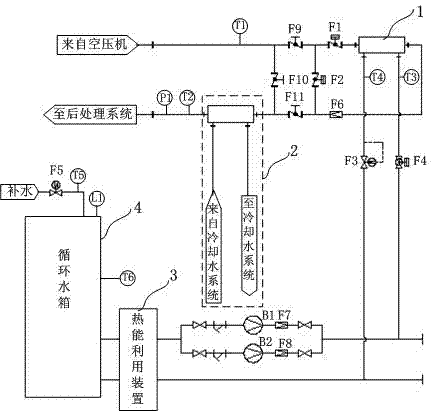

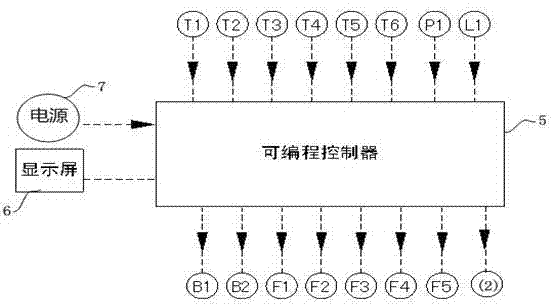

[0019] Example: as figure 1 , figure 2 As shown, the present invention is a compressed air heat recovery and control system. The compressed air output port of the air compressor is sequentially connected to the first manual valve F9, the intake pneumatic valve F1, the heat exchanger 1, the one-way valve F6, the third manual valve F11, the water cooling system 2 and the after-treatment system of the compressed air; The first manual valve F9 is installed between the air inlet of the air intake pneumatic valve F1 and the air outlet of the air compressor (compressed air output port), between the air inlet of the first manual valve F9 and the air inlet of the water cooling system 2 ( The second manual valve F10 is installed between the water-cooled compressed air inlet), and the third manual valve F11 is installed between the air outlet of the bypass pneumatic valve F2 and the air inlet of the water-cooling system 2; the circulating water inlet of the heat exchanger 1 is sequenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com