An Energy Saving Priority Unloading Valve

A technology of priority valve and unloading valve, used in fluid pressure actuation devices, servo motor components, mechanical equipment, etc., can solve the problem of low popularization rate, not getting quick application, variable steering hydraulic system manufacturing cost, maintenance The problem of high cost, to achieve the effect of reducing wear, slowing down the closing speed, and reducing the pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

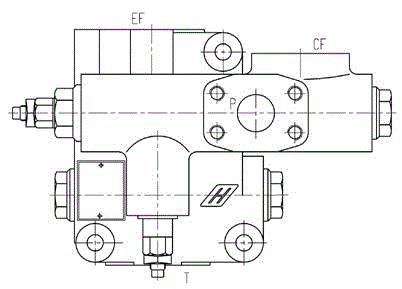

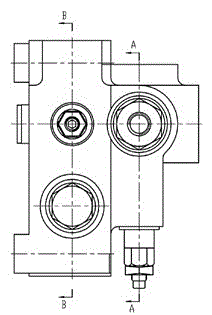

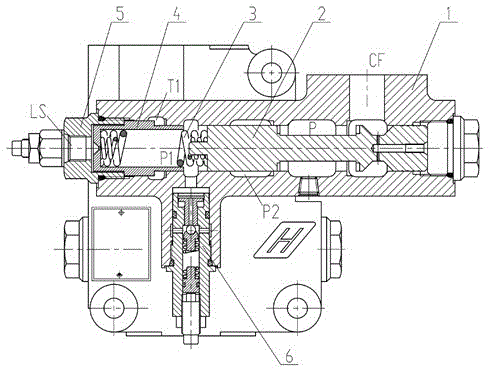

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

[0026] Such as Figure 1-7 As shown, an energy-saving priority unloading valve includes valve body 1, priority valve core 2, priority valve spring 3, slide valve 4, LS control port plug 5, LS relief valve 6, equivalent unloading one-way Valve 7, unloading safety valve 8, unloading valve core 9, unloading valve spring 10, limit screw plug 11, movable valve seat 12, priority valve spring 3 is set on the left side of priority valve core 2, priority valve A spool valve 4 is set between the spring 3 and the LS control port plug 5, and there are 5 oil passages on the priority valve hole: from right to left, the oil passage CF connected with the steering gear, and the oil passage of the steering pump oil inlet P. Priority valve diversion oil passage P2, priority valve left cavity oil passage P1, oil return passage T1; there are 3 oil passages on the unloading valve hole: from ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com