Exhaust gas treatment method and system in polysilicon production process

A production process and exhaust gas treatment technology, applied in separation methods, chemical instruments and methods, vapor condensation, etc., can solve the problems of low efficiency, increased equipment investment, and high investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

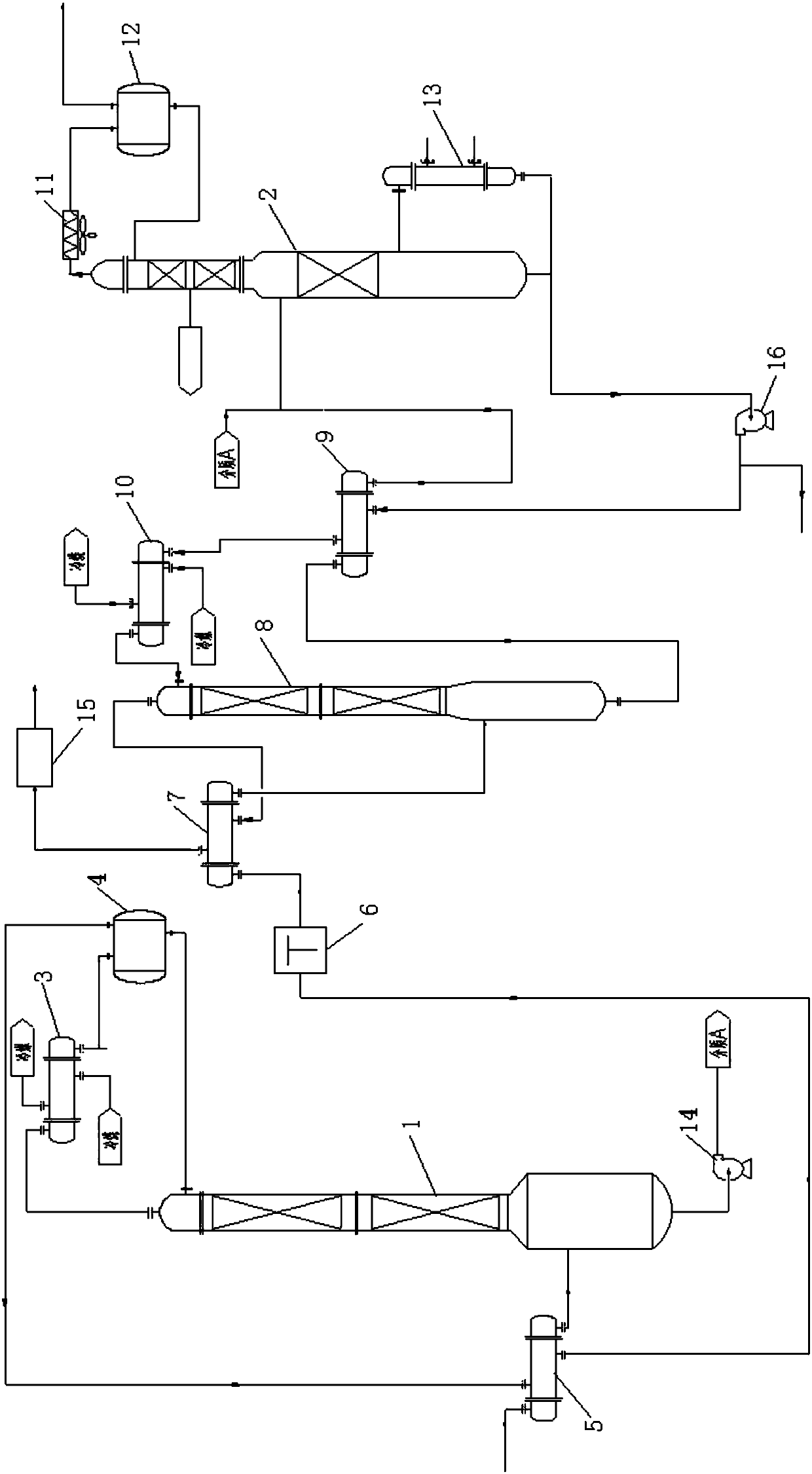

[0067] This embodiment provides a tail gas treatment system in the polysilicon production process, including:

[0068] The tail gas cooling tower is used to cool, liquefy and separate the tail gas in the polysilicon production process to obtain the bottom liquid of the tail gas cooling tower.

[0069]The separation tower is connected to the tower bottom of the tail gas cooling tower, and is used to pass the tower bottom liquid of the tail gas cooling tower into the separation tower for rectification and purification, and collect the top gas at the top of the separation tower. The top gas includes hydrogen, Hydrogen chloride; the side line production liquid is produced at the top side line of the separation tower or the upper part of the separation tower, and the side line production liquid includes trichlorosilane and dichlorodihydrosilane; the bottom liquid of the separation tower is collected at the bottom of the separation tower , the bottom liquid of the separation tower i...

Embodiment 2

[0079] This embodiment provides a tail gas treatment method in the polysilicon production process using the tail gas treatment system in the polysilicon production process in the above-mentioned embodiment 1. The difference from the method in embodiment 1 is:

[0080] In this embodiment, the number of theoretical plates of the separation tower is 90 to 160, and the reflux ratio of the separation tower is 10, and the feed position entering the separation tower is the 50th to 80th theoretical plate downwards from the top of the separation tower. In the side line of the separation tower, the position of the side line production liquid is the first theoretical plate downward from the top of the separation tower.

[0081] In the present embodiment, the mol ratio of trichlorosilane in the side draw liquid of the separation tower is 95mol%; the tower still liquid of the separation tower contains trichlorosilane, wherein, the content of silicon tetrachloride The molar ratio is 90 mol%...

Embodiment 3

[0084] This embodiment provides a tail gas treatment method in the polysilicon production process using the tail gas treatment system in the polysilicon production process in the above-mentioned embodiment 1. The difference from the method in embodiment 1 is:

[0085] In this embodiment, the number of theoretical plates of the separation tower is 90 to 160, and the reflux ratio of the separation tower is 7, and the feed position entering the separation tower is the 50th to 80th theoretical plate downwards from the top of the separation tower. In the side line of the separation tower, the position of the side line production liquid is the 35th theoretical plate downward from the top of the separation tower.

[0086] In the present embodiment, the mol ratio of trichlorosilane in the side stream production liquid of the separation tower is 90mol%; The molar ratio is 95 mol%.

[0087] In this embodiment, the pressure at the top of the separation tower is 0.3Mpa, the temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com