Thermal vibration joint test device and method of flange sealing structure under complicated loaded conditions

A technology of flange sealing and test equipment, which is applied in the direction of machine/structural component testing, measuring equipment, vibration testing, etc., and can solve problems such as no test method reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Assess the heat-shock joint test of the flange sealing structure at 330°C, applying a flange axial force of 15000N (allowable deviation 20%) and a flange lateral force of 4000N (allowable deviation 20%), and a sealing pressure of 0.95MPa.

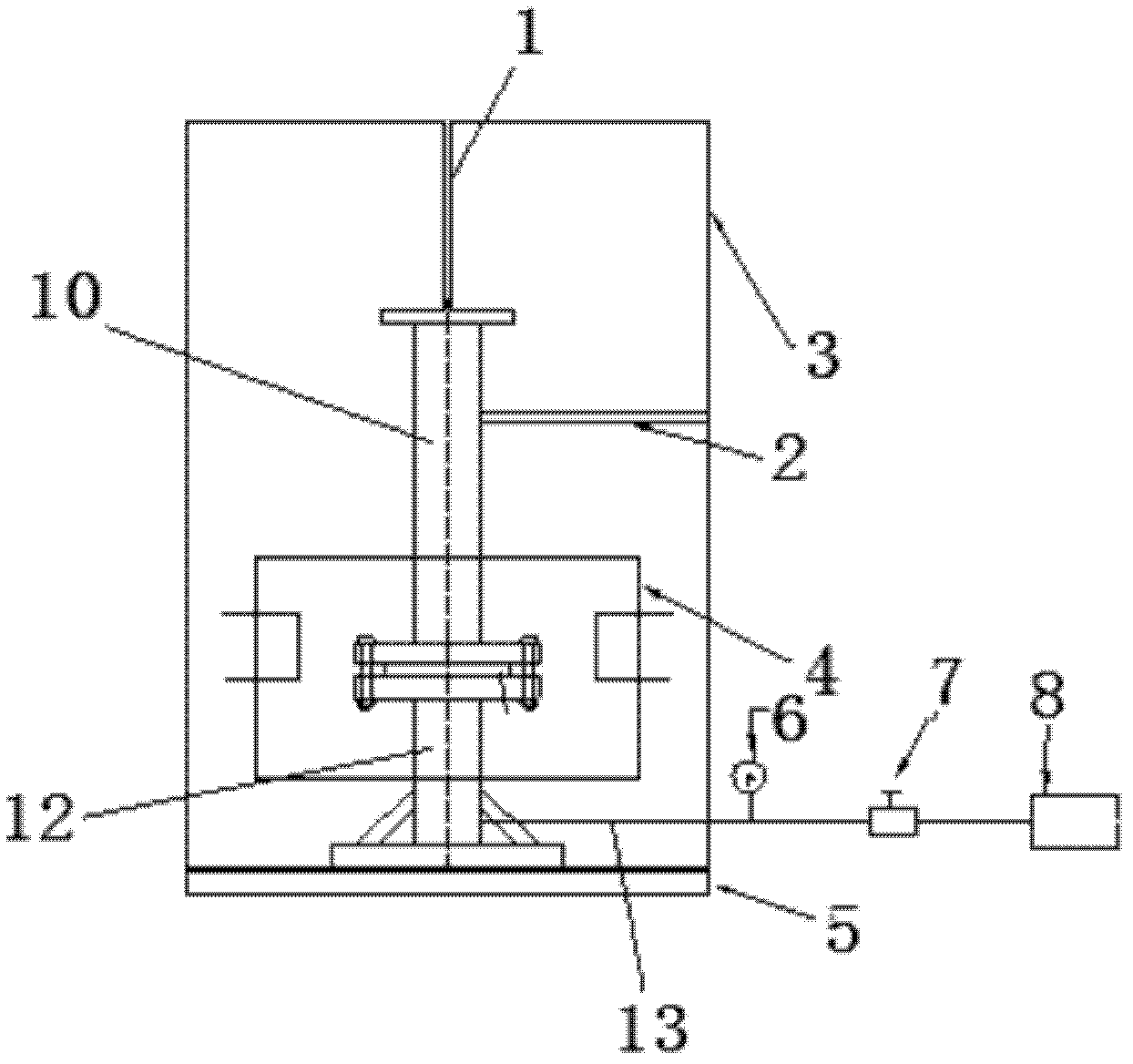

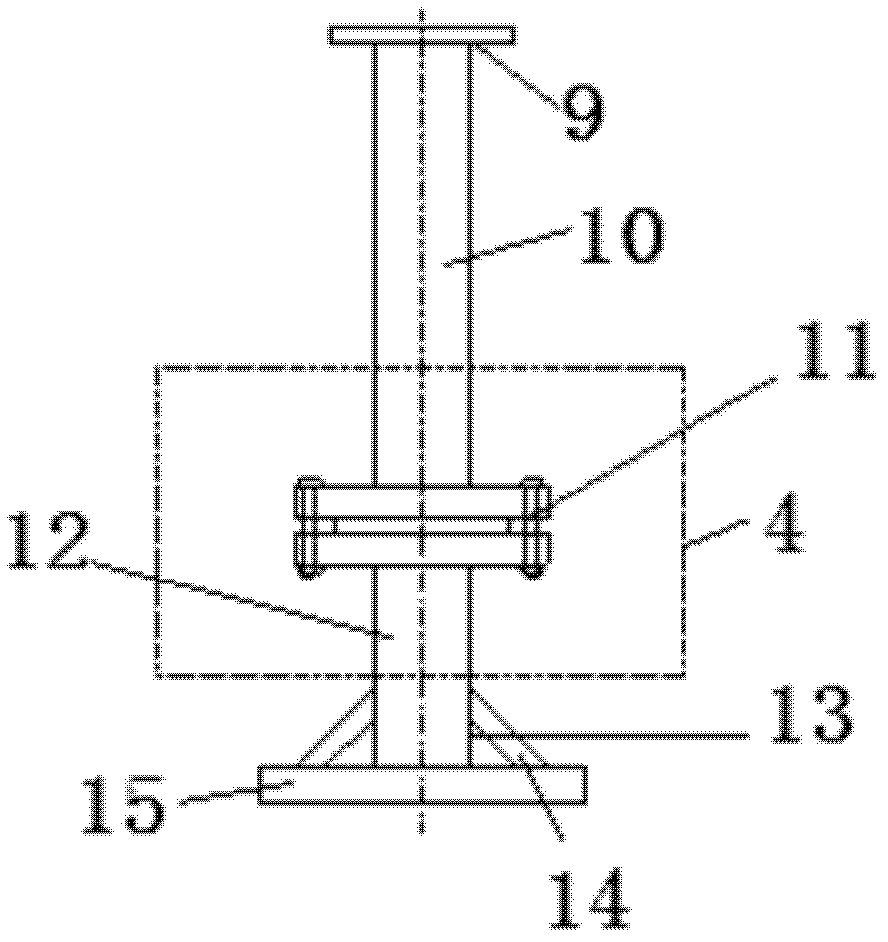

[0030] The structure of the test device is as figure 1 and figure 2 shown. The device includes a force-applying pipe section 10 with a flange at the lower end and a load-bearing pipe section 12 with a flange at the upper end. The flange sealing structure to be tested is placed on the flange plate and the load-bearing pipe section 12 of the force-applying pipe section 10 arranged up and down. Between the flanges, then the two flanges are sealed and fastened by several bolts 11 and nuts.

[0031] Be welded with connection bottom plate 15 at load-bearing pipe section 12 bottoms, weld several reinforcing ribs 14 between load-bearing pipe section 12 and connection bottom plate 15, connection bottom plate 15 is vertically fixedly instal...

Embodiment 2

[0051] Assess the heat-shock joint test of the flange sealing structure at 360°C, applying flange axial force of 16000N (allowable deviation 20%) and flange lateral force of 2000N (allowable deviation 20%), and sealing pressure of 1.25MPa.

[0052] The structure of the test device is basically the same as in Example 1.

[0053] The test method is as follows:

[0054] (a) if figure 1 As shown, the flange sealing structure to be tested is placed between the two flanges of the force-applying pipe section 10 with a flange at the lower end and the load-bearing pipe section 12 with a flange at the upper end arranged up and down, wherein the force-applying pipe section The top end of 10 is welded with a connecting top plate 9, and the bottom end of the load-bearing pipe section 12 is welded with a connecting bottom plate 15; then the two flanges are sealed and fastened by several bolts 11 and nuts;

[0055] (b) Use bolts and nuts to vertically fix the force-applying pipe section 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com