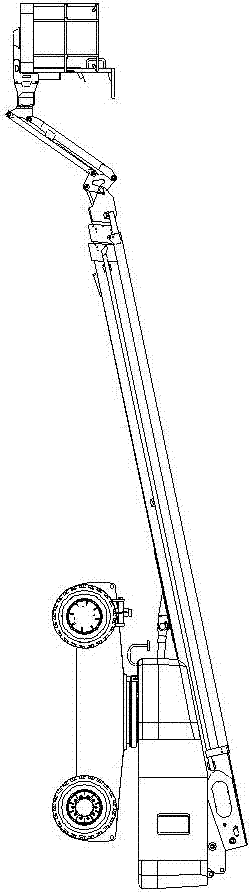

Versatile aerial work platform

A kind of high-altitude work platform, multi-functional technology, applied in the direction of lifting device, etc., can solve the problems of low disassembly efficiency, high cost, consumption, etc., and achieve the effect of reducing pipeline layout cost, high disassembly efficiency and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

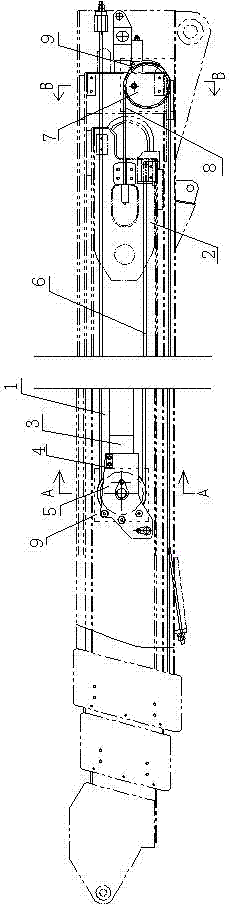

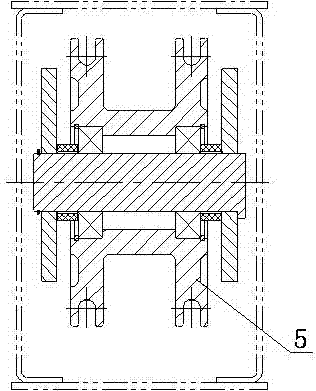

[0030] Such as Figure 1 to Figure 10, the present invention relates to a multifunctional aerial work platform, which is composed of a chassis, a slewing platform, a boom, a manned platform, an electric control system and a hydraulic system, wherein the boom includes a main arm 1, a middle arm 2, and a small arm 3 And the flying arm 11, wherein the small arm 3 is set in the middle arm 2, the middle arm 2 is set in the female arm 1, the front end of the small arm 3 is connected with the flying arm 11, and the rear end of the female arm 1 is connected with the piston of the telescopic cylinder 4 The rod is fixed, and the cylinder barrel of the telescopic oil cylinder 4 is fixed to the rear end of the middle arm 2. The two sides of the head of the telescopic oil cylinder 4 cooperate with the left and right sliders of the oil cylinder, and the left and right sliders of the oil cylinder are arranged on the track of the forearm 3, so that Can slide back and forth in the forearm 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com