Bristle trimming detection device for brush roller production

A detection device and brush roller technology, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of low efficiency and manpower consumption, and achieve the effects of high detection efficiency, improved efficiency, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

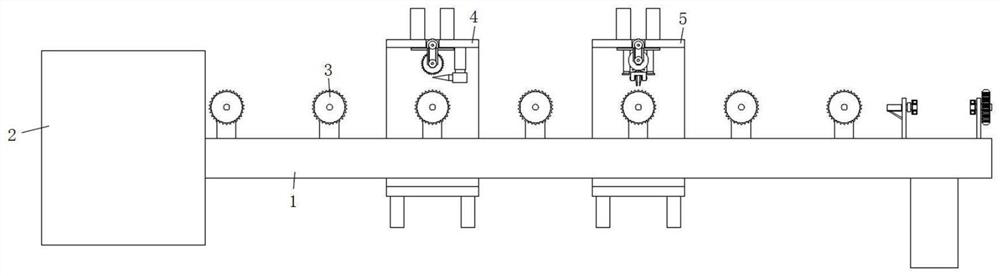

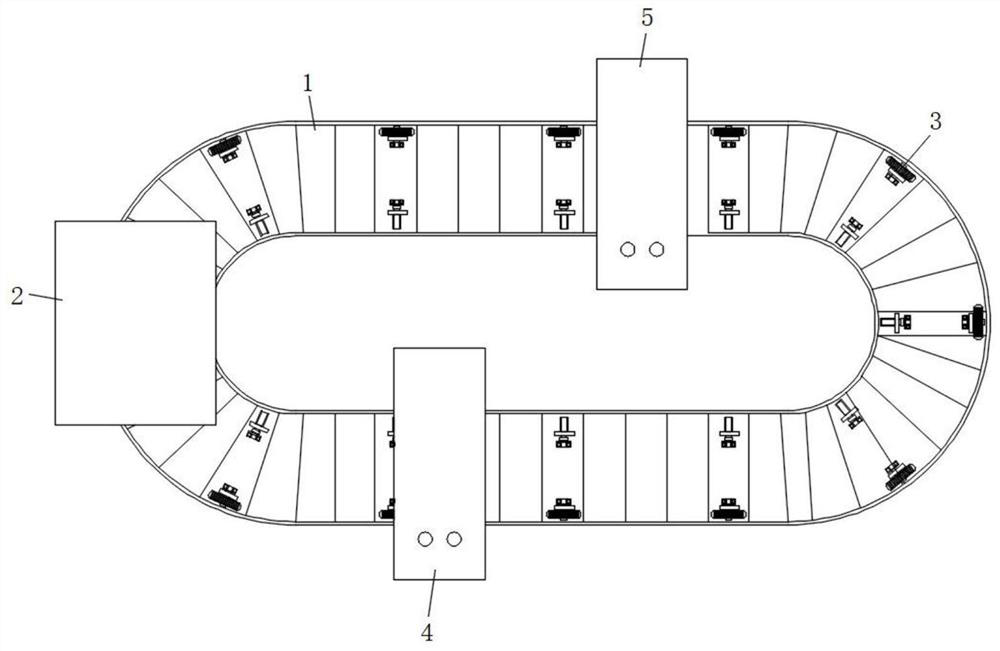

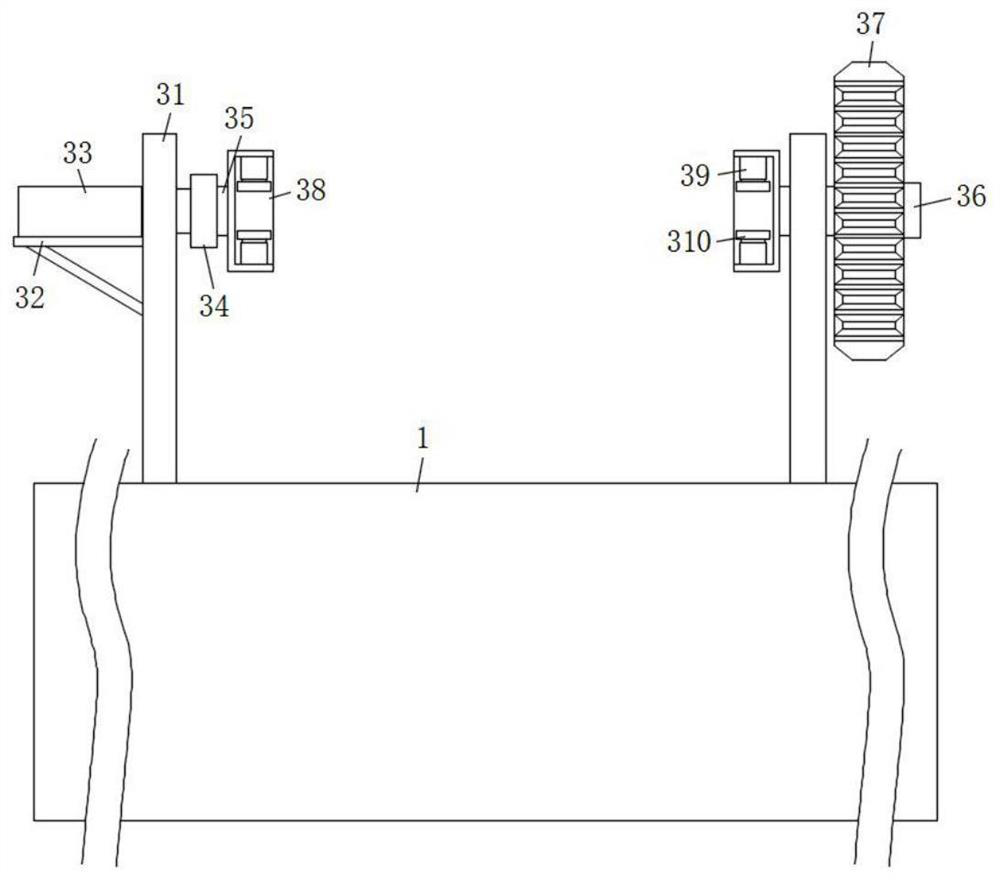

[0034] refer to Figure 1-7, a kind of hair trimming detection device for brush roll production, comprising a conveyor chain plate 1, a drive box 2 is erected on one side of the conveyor chain plate 1, the output end of the drive box body 2 is fixedly connected to the input end of the conveyor chain plate 1, and the conveyor chain plate The chain plate of the plate 1 is fixed with a temporary fixing mechanism 3 for the brush roller. With the help of the conveying chain plate 1, the feeding, trimming, detection and unloading of the brush roller are carried out synchronously, thereby greatly improving the speed of brush roller preparation, and providing brush roller High-efficiency production provides a certain guarantee. The brush roller temporary fixing mechanism 3 includes a mounting seat 31. There are two mounting seats 31 and are fixed on the same conveyor chain plate 1. The upper side of the rear mounting seat 31 is fixed with a horizontal Frame 32, the top surface of hori...

Embodiment 2

[0036] like Image 6 and 7 As shown, the present embodiment is basically the same as Embodiment 1. Preferably, the trimming mechanism 4 includes a working box one 41, and the rear side of the inner top surface of the working box one 41 is fixedly connected with an electric telescopic rod two 42 by screws, and the electric telescopic rod two 42 The output end is fixedly connected with the installation strip 43 by screws, and one side of the installation strip 43 is fixedly connected with the trimming knife 44 by screws, and the front side of the outer top of the work box one 41 is also fixed with the electric telescopic rod three 45, and the electric telescopic rod three 45 outputs Both ends are fixedly connected with a connecting piece-46 by screws, and the two connecting pieces-46 are fixedly connected with a support seat-47 at one end close to each other. The outer wall of —48 is also fixedly connected with drive gear —49 by screws, and the top side of two connecting pieces...

Embodiment 3

[0040] like image 3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, there are two electric telescopic rods one 39 and they are fixed on the inner top surface and bottom surface of the installation dish 38 .

[0041] In this embodiment, there are two electric telescopic rods 1 39, so that the temporary fixation of the brush roller is more stable, thereby providing good quality assurance for trimming and testing of the brush roller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com