Full-automatic re-tightening device for fuel tank strap of heavy vehicle

A technology for heavy-duty vehicles and fuel tanks, applied in vehicle parts, transportation and packaging, metal processing, etc., can solve problems such as forgetting to retighten fuel tank straps, potential safety hazards, and not paying attention to retightening fuel tank straps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

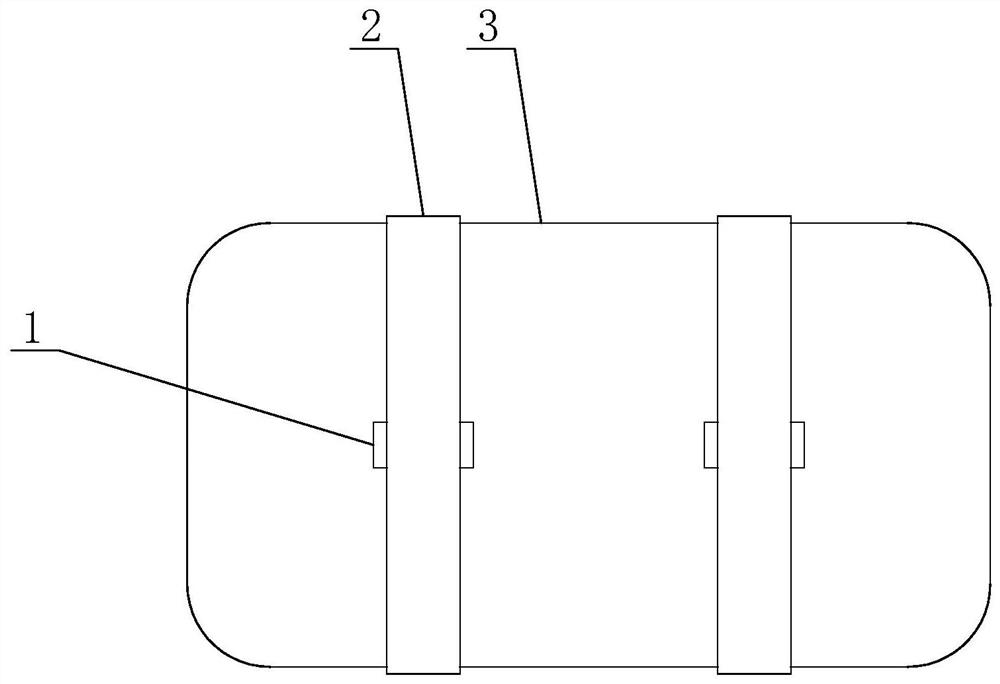

[0021] Example: as attached Figure 1-3 As shown, the present invention is a full-automatic retightening device for heavy-duty vehicle fuel tank straps, including:

[0022] A pressure sensor 1, the pressure sensor 1 is installed between the strap 2 and the fuel tank 3, and is used to monitor the tightness of the strap of the fuel tank in real time;

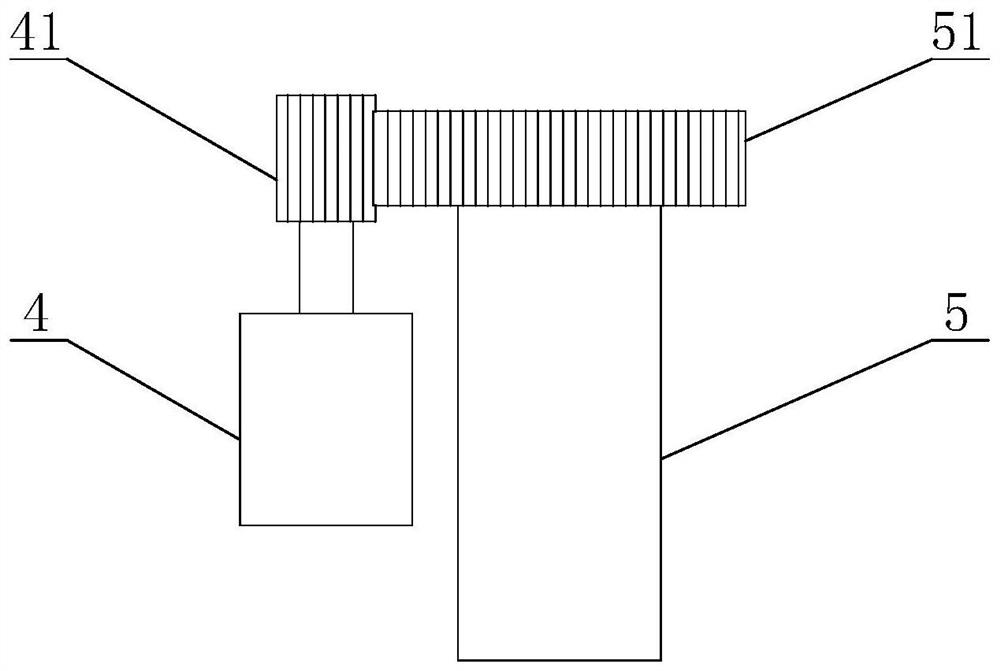

[0023] The retightening motor 4, the retightening motor 4 is used as an actuator, installed on one side of the fastening bolt 5, can be directly fixed on the fuel tank 3, or can be installed on the frame near the fuel tank 3, for automatic retightening Tight power output, gear 41 is installed on the output shaft of described re-tightening motor 4, described fastening bolt 5 is provided with the tooth 51 that meshes with gear 41, and re-tightening motor 4 can drive fastening bolt 5 to rotate;

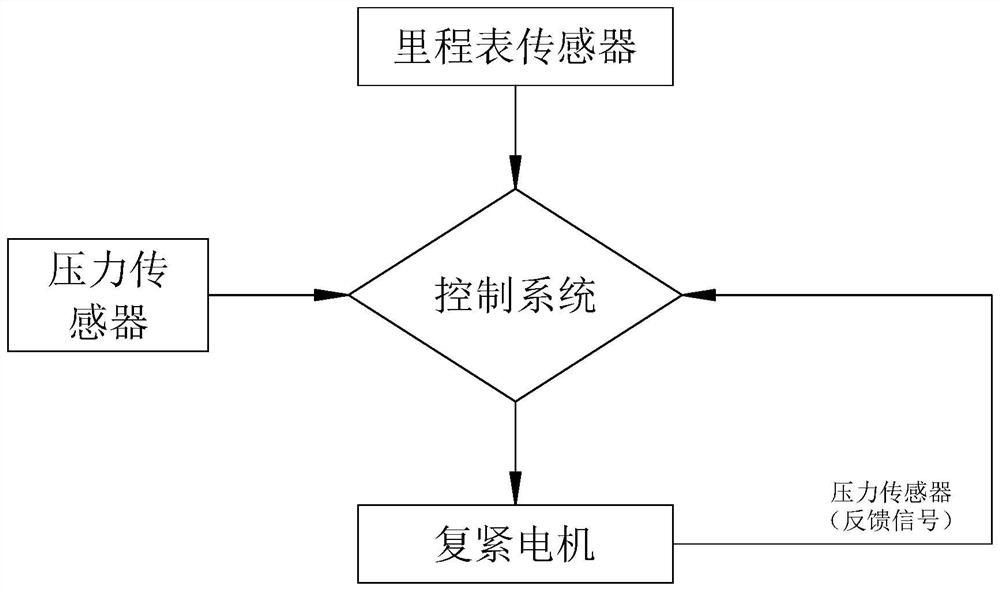

[0024] The control system is used to receive the sensor detection signal, analyze and judge the detection signal, and then issue a command...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com