CO compensation supply system on CO conveying pipeline and application of CO compensation supply system

A transmission pipeline and supply system technology, applied in the field of CO supply system, can solve problems such as CO product interruption, equipment damage, and vehicle jump loss, and achieve the effects of convenient operation, guaranteed reliability, guaranteed purity and pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

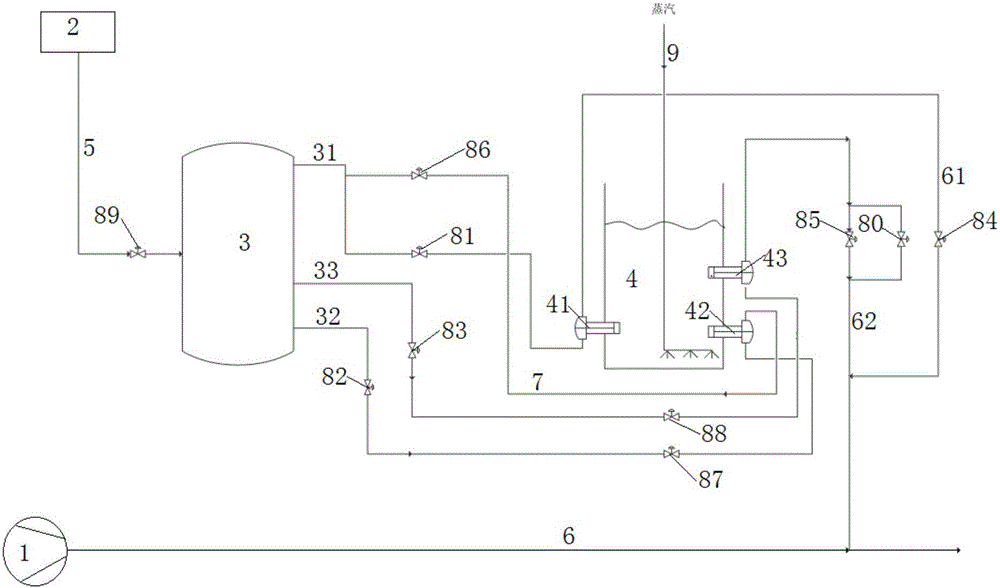

[0029] A CO compensation supply system on a CO delivery pipeline, such as figure 1 As shown, it is used to provide CO compensation supply to the CO delivery pipeline 6 connected to the outlet of the compressor 1. The CO compensation supply system includes a cold box 2 for supplying liquid CO, a CO liquid tank 3 for storing liquid CO, and In the gasifier 4 for vaporizing liquid CO, the cold box 2 is connected to the CO liquid tank 3 through the liquid CO supply pipeline 5, and the gasifier 4 is provided with three heat exchangers for vaporizing the liquid CO, respectively the first The heat exchanger 41, the second heat exchanger 42, the third heat exchanger 43, and the CO liquid tank 3 lead out three pipelines, respectively the first pipeline 31, the second pipeline 32, the third pipeline 33, the first pipeline 31 and the second pipeline A heat exchanger 41 is connected, the second pipeline 32 is connected with the second heat exchanger 42, the third pipeline 33 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com