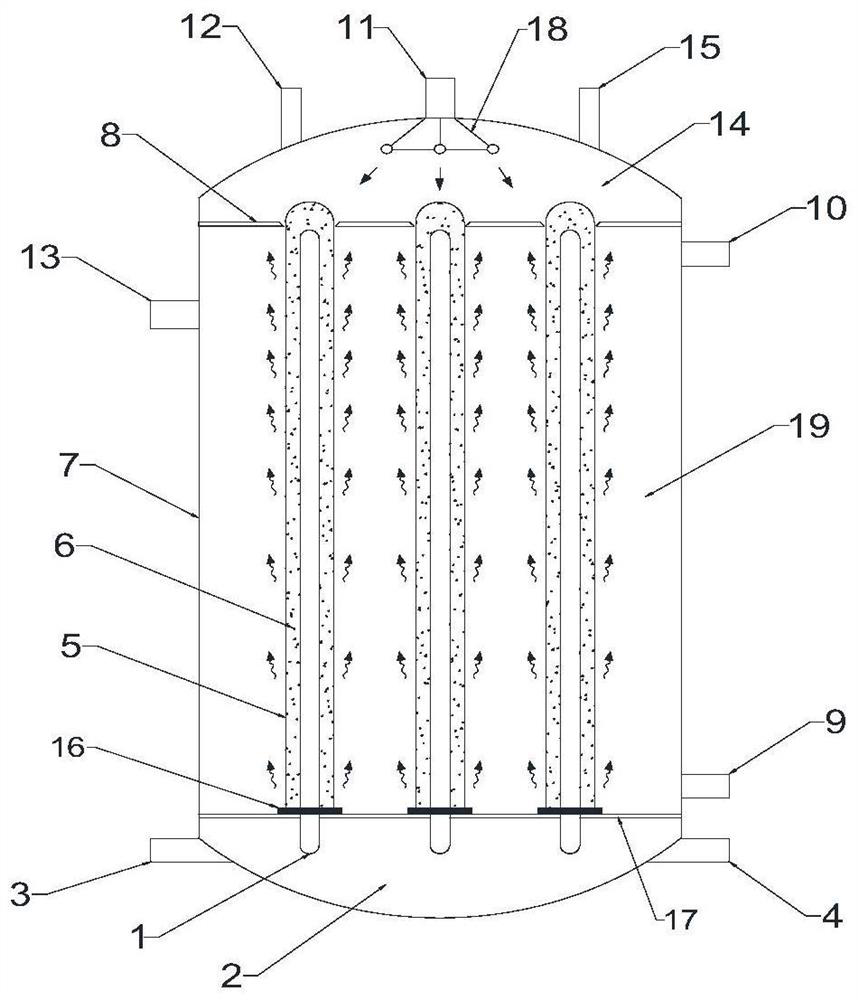

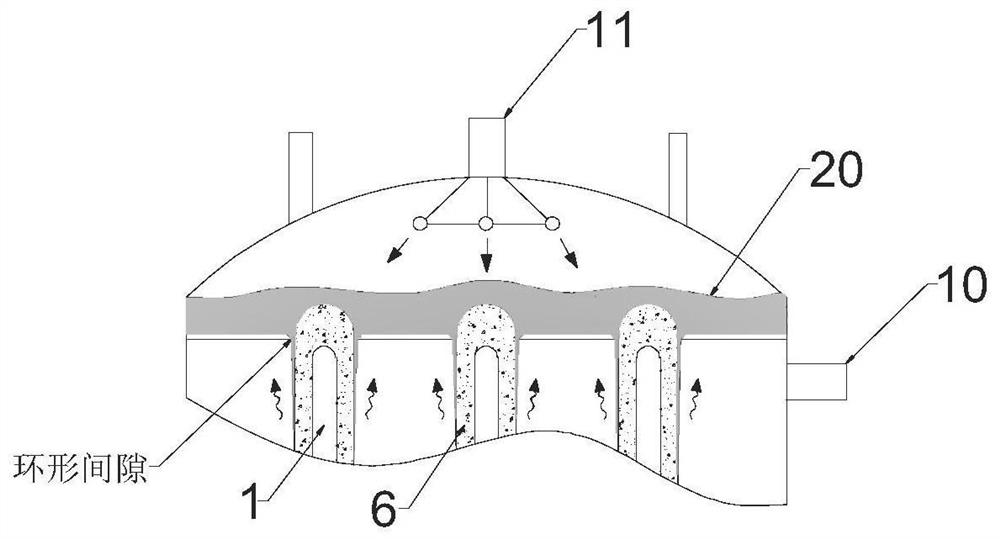

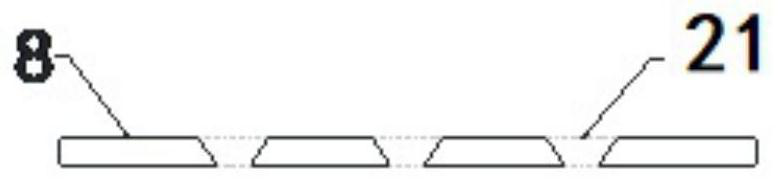

Phase change heat storage type falling film evaporator

A technology of falling film evaporator and phase change heat storage, which is applied in vertical tube evaporator, evaporator accessories, evaporation, etc., to improve evaporation efficiency, ensure temperature and pressure stability, and solve scaling and non-isothermal heat transfer problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Barium Hydroxide Octahydrate (Ba(OH) 2 ·8H 2 O) is a functional material with great development potential among inorganic phase change heat storage materials. Suitable for storage and temperature regulation of medium and low temperature heat sources. Therefore, this implementation case uses Ba(OH) 2 ·8H 2 O is used as the phase-change heat storage material in the thin-film evaporation tube, and pure water is used as the liquid material for evaporation, and the parameters are set according to their phase-change temperature characteristics. The implementation examples are as follows.

[0035] According to the structural design drawing of the inventive device, each component part of the device is made, and the connection and the potting of the phase change heat storage material are carried out according to the designed structure. After the above preparatory work is completed, according to the working principle of the device, the operation steps are as follows:

[0036...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com