Simple high-temperature testing device and method for flange rubber sealing element

A technology of rubber seals, high temperature test, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc. The effect of fast heat transfer and saving development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

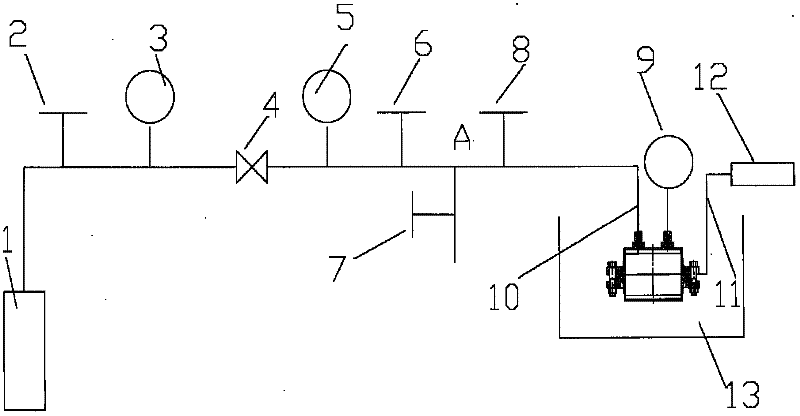

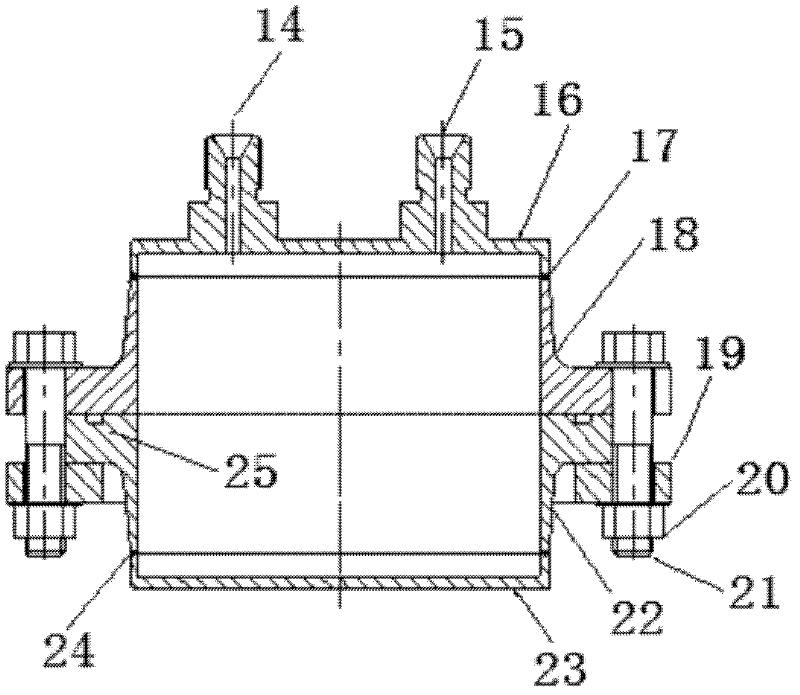

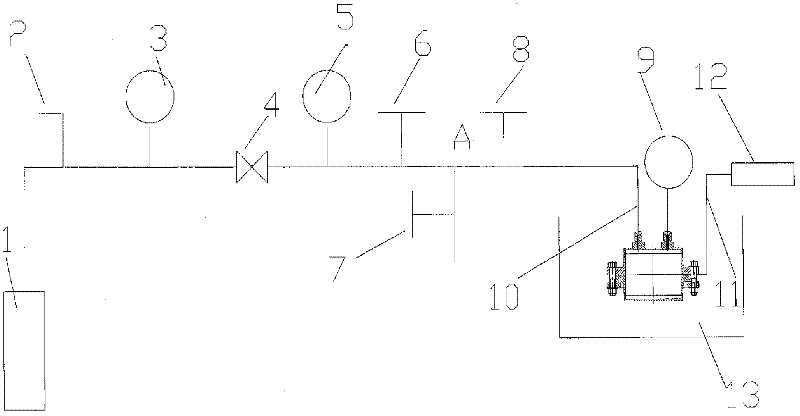

[0026] like figure 1 and figure 2 As shown, a simple high-temperature test device for a flange rubber seal according to the present invention includes an upper flange 18, a lower flange 22 is docked with the upper flange 18, and the lower flange 19 is clamped by a loop ring 19. flange 22, at the same time pass through the loop ring 19 and the upper flange 18 through several bolts 21 arranged in the circumferential direction to realize the fastening connection of the upper and lower flanges; set a ring groove on the end surface of the lower flange 22 that is in contact with the upper flange 18 , is the sealing groove 25 for assembling the flange rubber seal to be tested;

[0027] At a distance of 20 mm from the end face of the upper flange 18, the upper cover 16 and the upper flange 18 are connected by welding, and the end face of the upper flange produces a flange flatness of 0.3 mm; the upper cover 16 has two nozzles 14 and 15 . At a distance of 50 mm from the end face of...

Embodiment 2

[0034] The simple and easy high temperature test method of a kind of flange rubber seal of the present invention, such as figure 1 and figure 2 As shown, it includes the following steps:

[0035] (a) Open a ring groove on the end face of the lower flange 22 that is in contact with the upper flange 18. In order to assemble the sealing groove 25 of the flange rubber seal to be tested, place the flange rubber seal to be tested on the seal Then the lower flange 22 is docked with the upper flange 18, and then the lower flange 22 is clamped by the loop ring 19, and at the same time, several bolts 21 arranged in the circumferential direction pass through the loop ring 19 and the upper flange 18 Realize the tight connection of the upper and lower flanges; the upper cover 16 is welded on the top of the upper flange 18 to seal the upper flange 18, and there are two nozzles 14 and 15 on the upper cover 16; the bottom cover 23 is welded on the bottom of the lower flange 22 , to seal th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com