Facial mask processing method

A processing method and mask technology, applied in liquid materials, solid materials, packaging, etc., can solve the problems of inability to meet various mold specifications, long intermittent time, and reduced work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A method for processing a facial mask, which satisfies the processing of facial masks of various models and specifications through facial mask processing equipment: comprising the following steps:

[0024] (1) Extrude the raw materials forming the mask in the form of extrusion, and adjust the stroke of extrusion up and down to achieve a variety of output volumes;

[0025] (2) pour the raw material of facial mask in the mold 13 by the form of rocking, regulate the size of the amplitude of rocking, pour into to realize the mold 13 of various specifications;

[0026] (3) the extruding and scraping of the mask raw material on the mold 13 finally forms the mask;

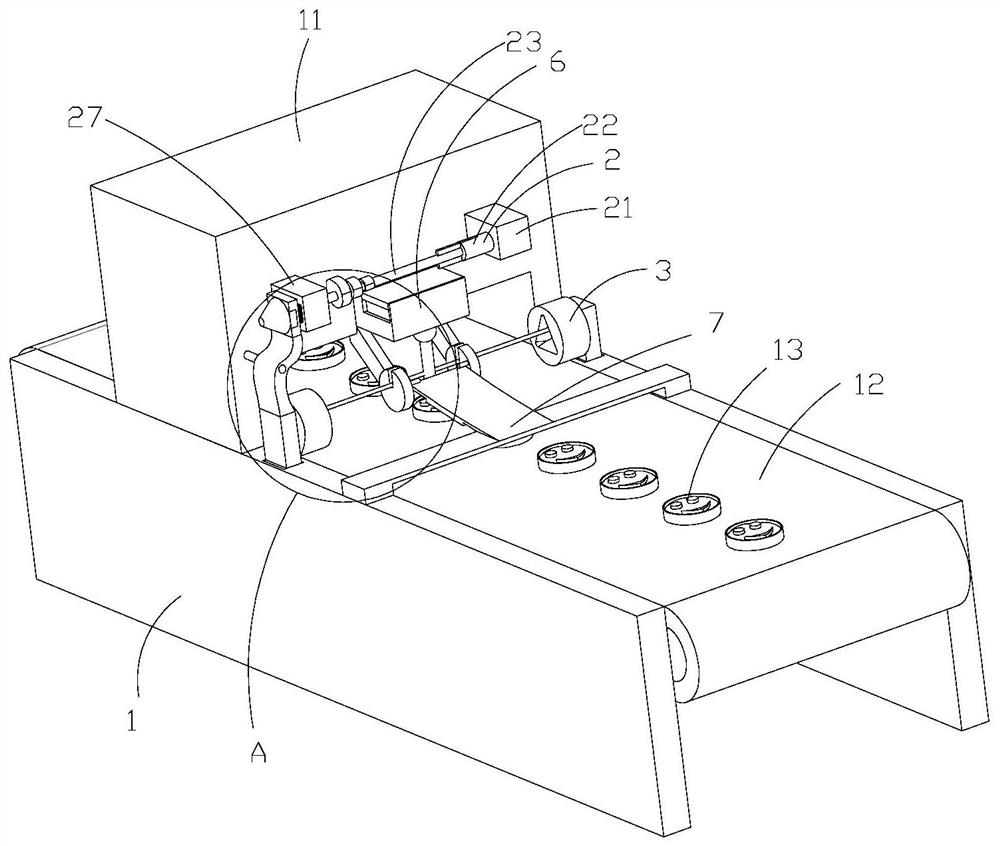

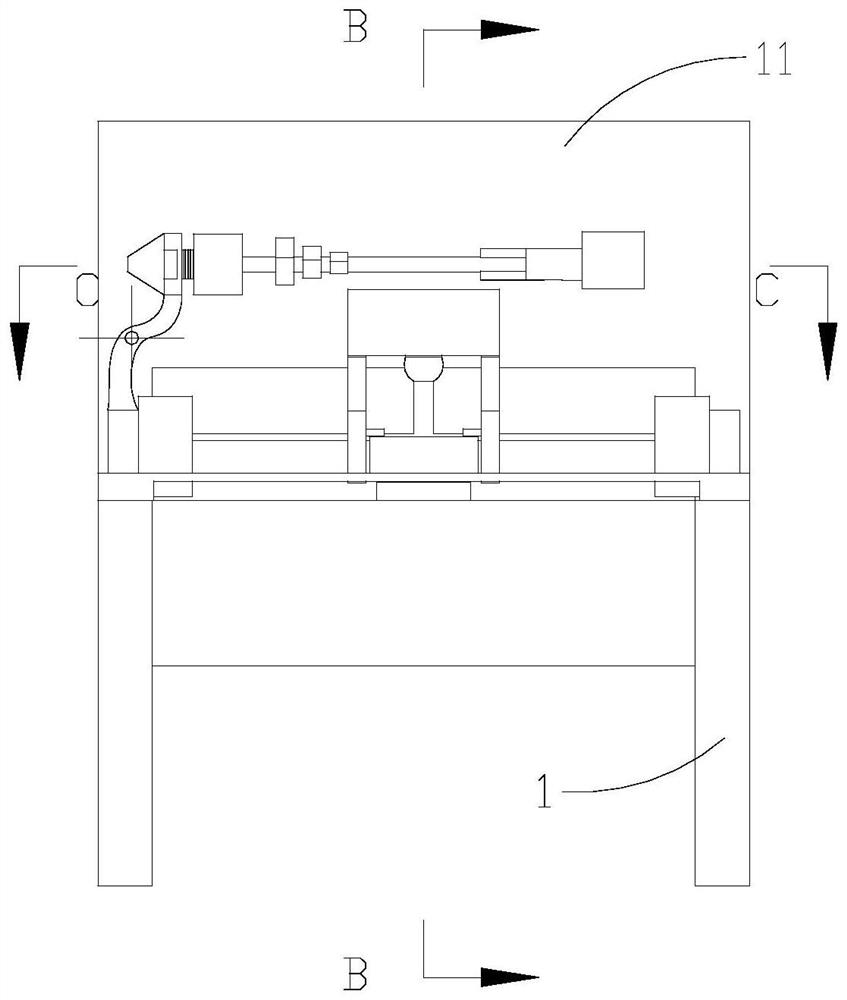

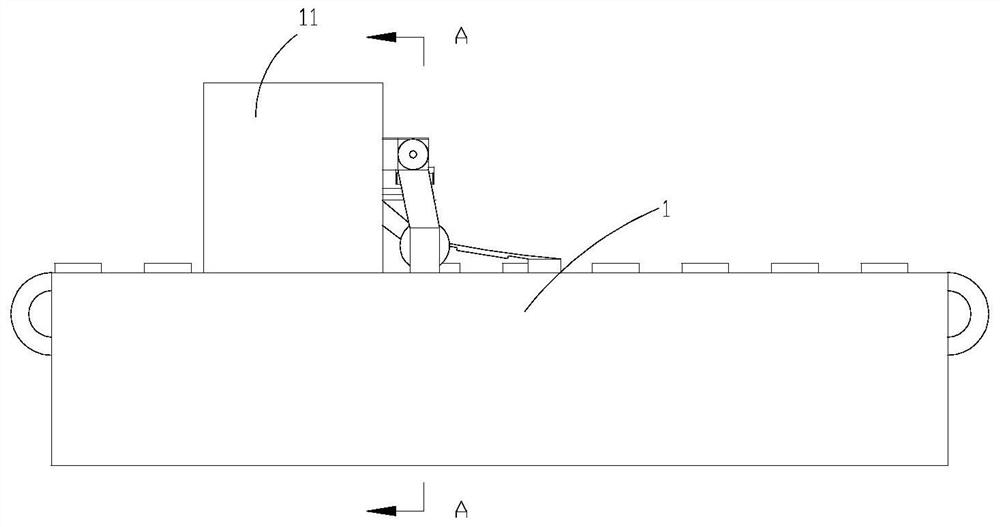

[0027] Such as Figure 1-9 As shown, wherein the mask processing equipment comprises a support frame 1, a raw material box 11, a conveyor belt 12, a mold 13, a first regulating part 2, a second regulating part 3, a discharge box 6, and an extruding part 7; the raw material case 11 is located at On the support fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com