Surface active polymer, preparation method thereof and application of surface active polymer as polymer oil-displacing agent

A surface-active, polymer technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as oil displacement and oil washing capacity needs to be further improved, reduce the investment in on-site injection equipment and facilities, and improve crude oil The effect of oil recovery rate and oil production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

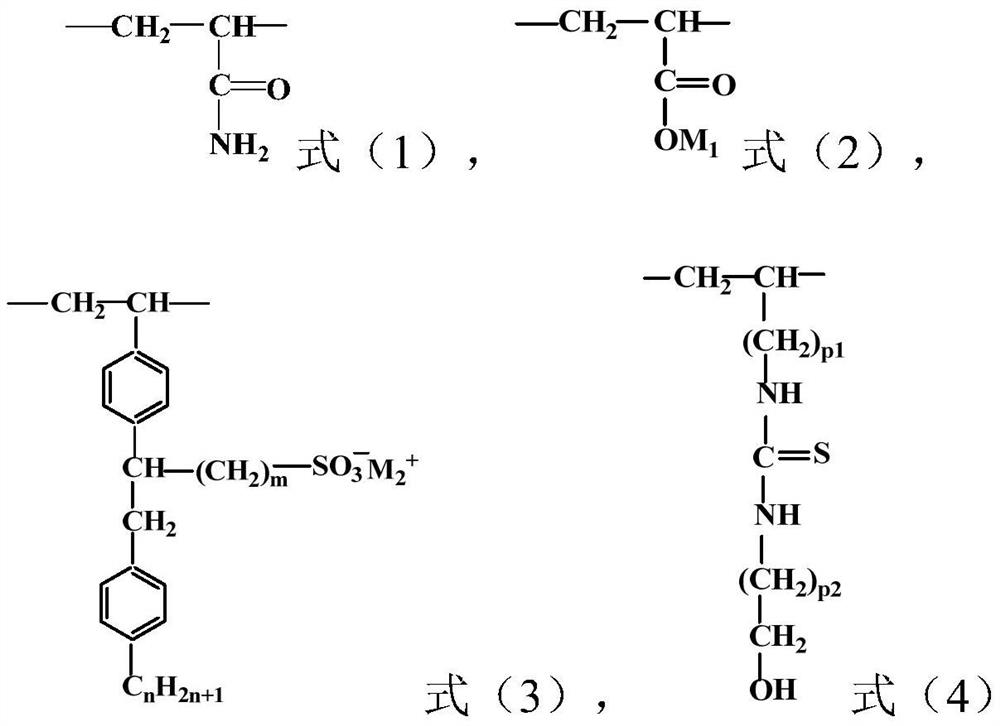

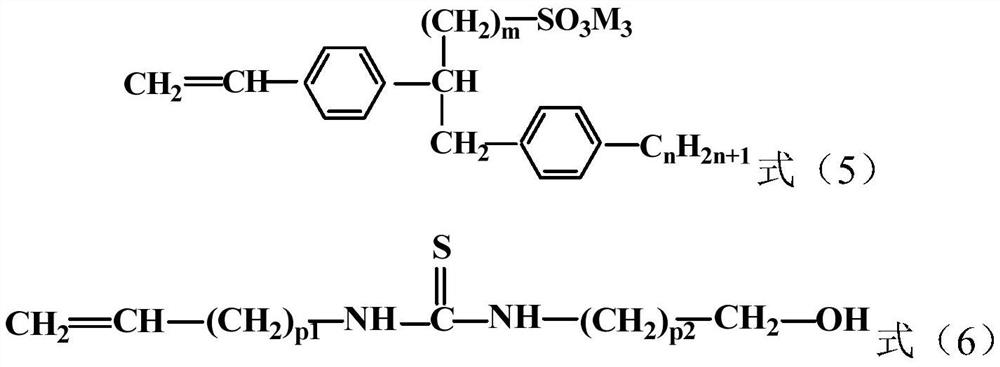

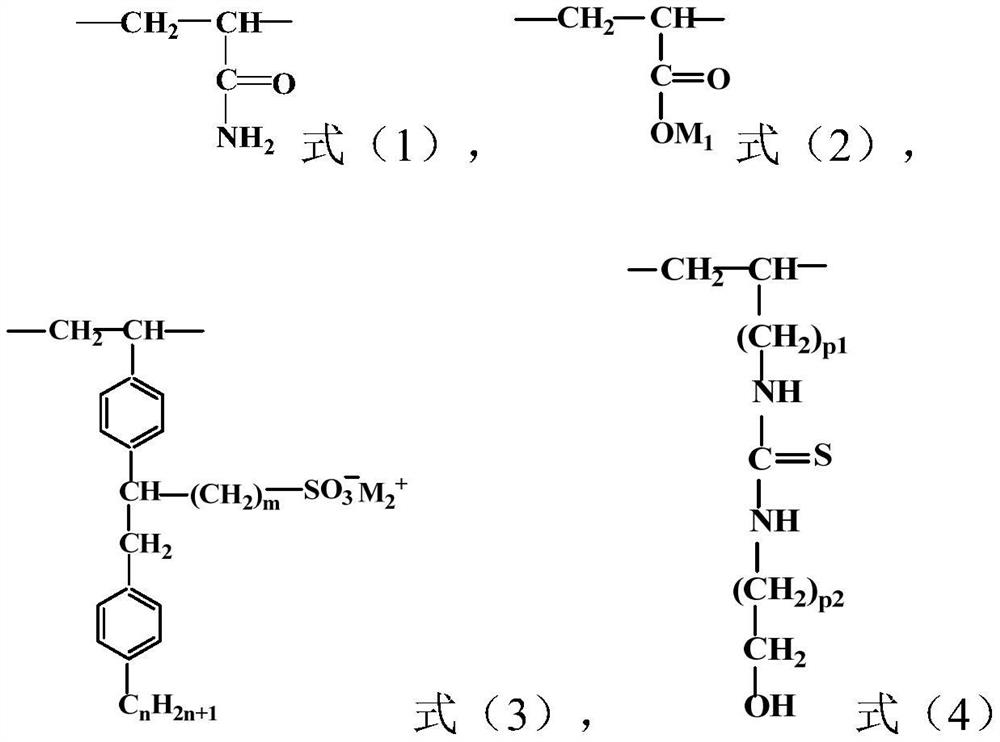

[0040] As mentioned above, the second aspect of the present invention provides a method for preparing a surface-active polymer, the method comprising: under solution polymerization conditions, in the presence of an initiator, a monomer mixture is polymerized in water, and the monomer mixture is polymerized in water. The bulk mixture contains monomer X, monomer Y and acrylamide, the monomer X is a monomer having the structure shown in formula (5), and the monomer Y is a monomer having the structure shown in formula (6); And based on the total amount of the monomer mixture, the content of the acrylamide is 65-99% by weight, the content of the monomer X is 0.5-25% by weight, and the content of the monomer Y is 0.5-15% by weight %;

[0041]

[0042] Among them, m is 1-8, n is 1-9, p1 and p2 are each independently 1-6; M 3 are alkali metals and / or H.

[0043] Preferably, based on the total amount of the monomer mixture, the content of the acrylamide is 74-96 wt %, the content ...

preparation example 1

[0085] 100mL of tetrahydrofuran was added to a 250mL there-necked flask, placed in a salt water bath at -10°C, and 0.1mol of terephthalene (that is, p-divinylbenzene, the same below) was added under stirring, and then 0.1mol of SO 3 , after the reaction is complete, add 0.1 mol of Grignard reagent of p-ethylbenzyl magnesium chloride dropwise, keep the reaction for 1 h after the dropwise addition, then add n-hexane to precipitate the product, and finally wash with n-hexane for more than three times. The product obtained by the nuclear magnetic test is the monomer X (m=1, n=2) having the structure represented by formula (5).

preparation example 2

[0087] 100mL of tetrahydrofuran was added to a 250mL three-necked flask, placed in a salt water bath at -10°C, and 0.1mol of terephthalene and 0.1mol of sodium chloromethanesulfonate were added under stirring (purchased from Bailingwei Technology Co., Ltd.) , then add 0.2g of boron trichloride as a catalyst, an addition reaction occurs, and after the reaction is complete, 0.1mol of Grignard reagent of p-hexylbenzyl magnesium chloride is added dropwise, and cuprous chloride is used as a catalyst. Incubate the reaction for another 1h, then add n-hexane to precipitate the product, and finally wash with n-hexane for more than three times. The product obtained by the nuclear magnetic test is confirmed to be the monomer X (m=2, n=6) with the structure shown in formula (5). ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com