Deep plugging control system for heavy oil thermal production well and steam steering method

A technology of plugging adjustment and system, applied in the direction of production fluid, wellbore/well components, chemical instruments and methods, etc., can solve the problems of low plugging strength, low oil recovery efficiency, deep steam cannot reach the effective remaining oil area, etc., to achieve Good plugging strength and erosion resistance, the effect of enhancing oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1 A kind of plugging adjusting and channeling agent

[0060] The plugging adjustment and channeling agent is composed of the following components and their contents: 1.0wt% elastic rubber powder, 1.0wt% molten oxidized asphalt, 0.05wt% partially hydrolyzed polyacrylamide, 0.03wt% sodium lauryl sulfate, and The amount is water.

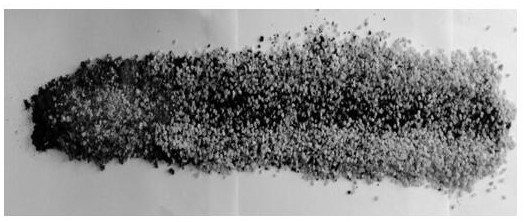

[0061] Performance test of the plugging agent for plugging adjustment and channeling

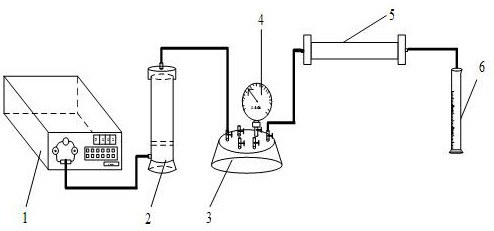

[0062] (1) Deep injection test. use as figure 1 The device shown is used for the deep injectability test of the plugging agent. The test steps are as follows: (1) Fill the sand filling pipe with white quartz sand. The particle size of the quartz sand is 5-10 mesh, and the size of the sand filling pipe is: 2.5cm in diameter and 50cm in length. (2) According to figure 1 Schematic connection of the experimental setup. (3) Inject the plugging adjustment and channeling agent described in Example 1 into the sand packing pipe. The particle size of e...

Embodiment 2

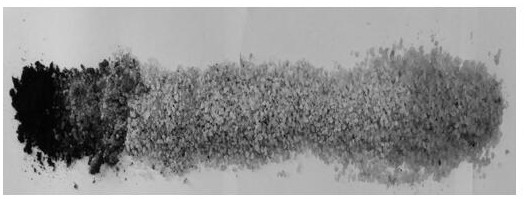

[0081] Embodiment 2 A plugging agent for regulating plugging and channeling

[0082] The plugging adjustment and channeling agent is composed of the following components and their contents: elastic rubber powder 0.5wt%, molten oxidized asphalt 1.0wt%, partially hydrolyzed polyacrylamide 0.05wt%, sodium dodecylbenzenesulfonate 0.03wt% , and the balance is water.

Embodiment 3

[0083] Embodiment 3 A kind of plugging adjusting and channeling agent

[0084] The plugging adjustment and channeling agent is composed of the following components and their contents: elastic rubber powder 0.5wt%, molten oxidized asphalt 2.0wt%, partially hydrolyzed polyacrylamide 0.05wt%, sodium dodecylbenzenesulfonate 0.03wt% , and the balance is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com