Plasma injection method and apparatus for insulation material spare parts

A technology of insulating materials and plasma, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems that the potential of insulating materials cannot be applied and is difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

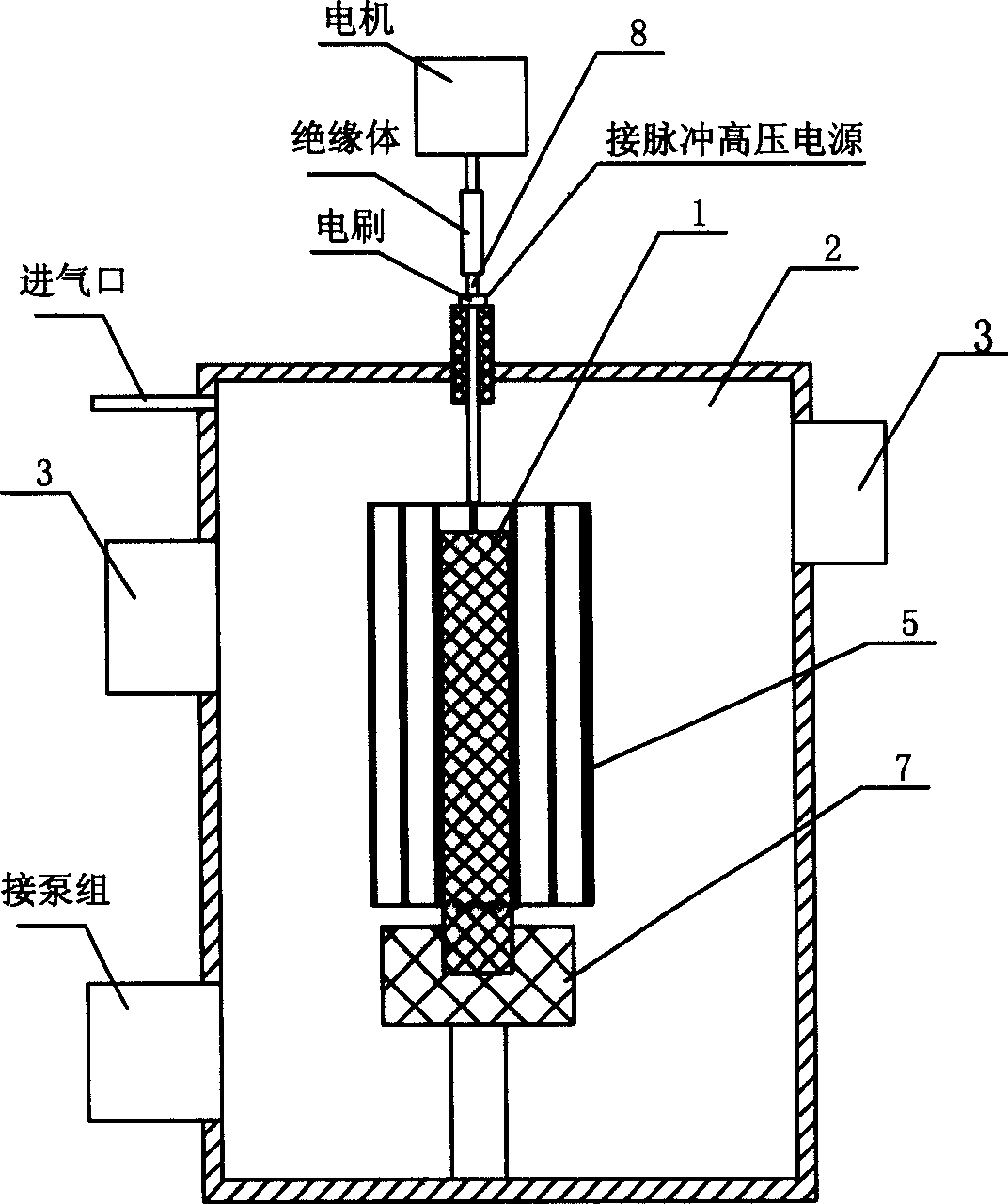

[0005] Embodiment 1: Insulating material parts plasma injection method, insulating material parts 1 are arranged in the vacuum chamber 2, the vacuum chamber 2 communicates with the plasma source 3, and a pulsed high-voltage power supply is arranged outside the insulating material parts 1 The metal strip 4 or the metal cylinder grid 5 of the negative electrode controls the relative rotation between the metal strip 4 or the metal cylinder grid 5 and the insulating material component 1 to realize the plasma injection of the insulating material component. The core of the invention is to obtain an equivalent negative potential near the surface of the columnar insulating part to attract ions in the plasma to promote the injection effect.

specific Embodiment approach 2

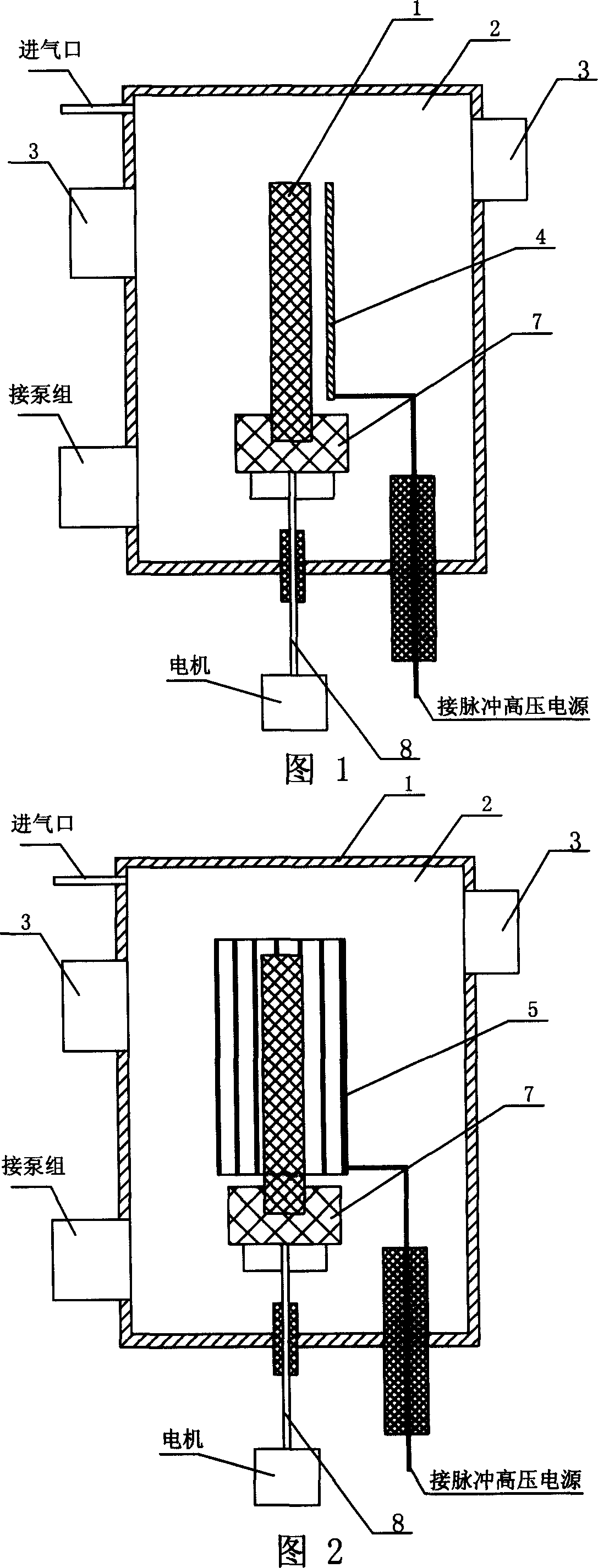

[0006] Specific embodiment two: Referring to Fig. 1, the plasma injection device for insulating material parts in this embodiment includes a vacuum chamber 2 communicated with a plasma source 3, and a columnar insulating material part 1 is arranged in the vacuum chamber 2, and the columnar Parts 1 made of insulating material are placed on a workpiece platform 7, which is connected to the external motor shaft 8 through a dynamic seal, and metal strips 4 are fixed around the parts 1 of insulating material, and the metal strip 4 is connected to the parts made of insulating material. The axes of the components 1 are parallel, and the metal strip 4 is connected to the negative pole of the pulse high-voltage power supply.

specific Embodiment approach 3

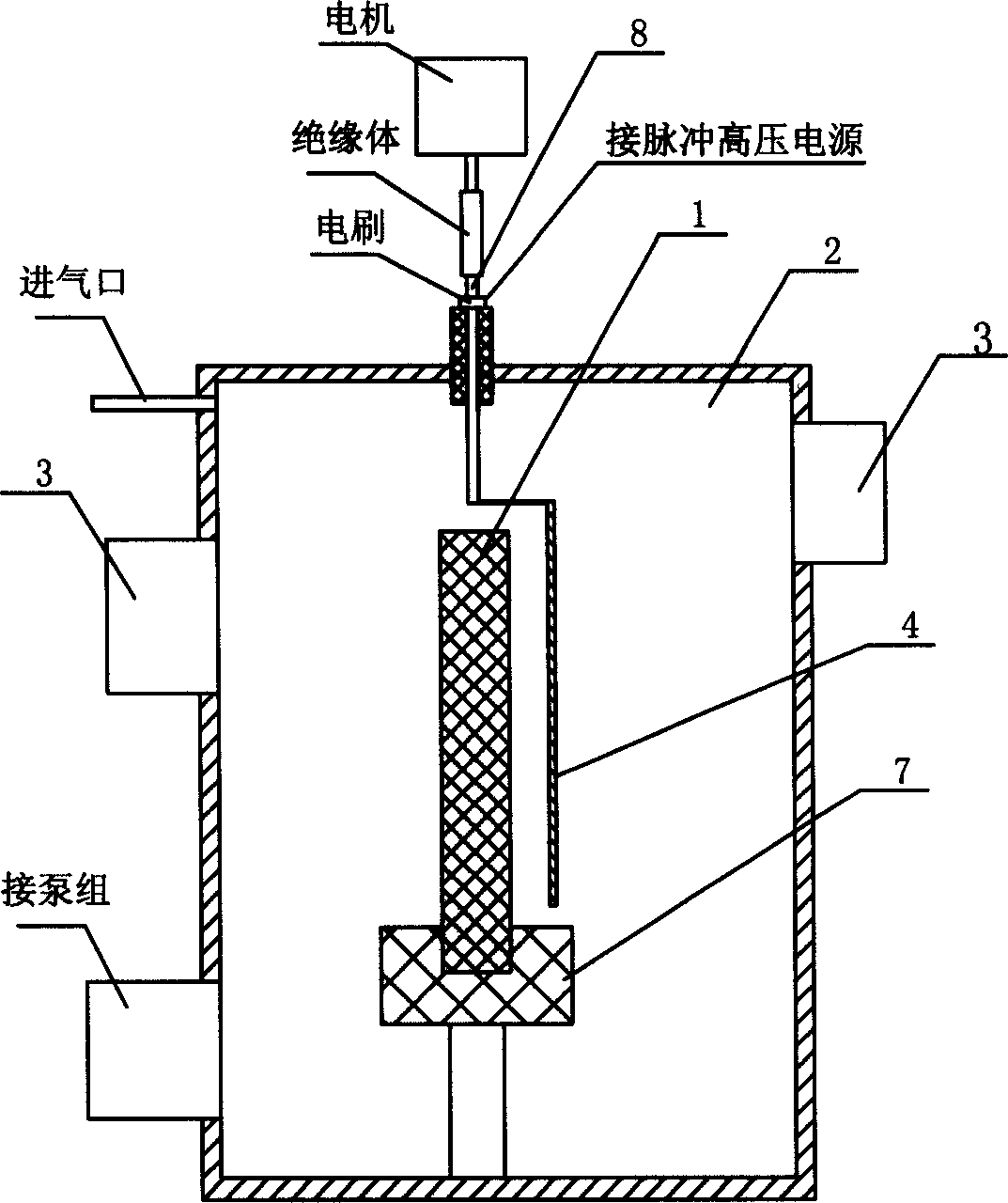

[0007] Specific embodiment three: Referring to Fig. 2, the difference between this embodiment and specific embodiment two is that the metal strip 4 is replaced by a metal barrel grid 5, and the metal barrel grid 5 is cylindrical, and the cylindrical metal barrel grid 5 Sleeved on the outside of the columnar insulating material part 1, and its axis coincides with the axis of the columnar insulating material part 1, the metal cylinder grid 5 has only warp threads and no weft threads.

[0008] The rotation of the motor can form the relative rotation of the insulating workpiece and the conductive cylindrical metal cylinder grid. When the high-voltage pulse is applied to the metal grid, the ions in the plasma will fly to the grid under the influence of the sub-potential of the grid. Since the grid has a large gap, most of the ions will fly through the grid gap. Injection into the interior of the workpiece of insulating material. But at this time, the shadow effect caused by the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com