A nozzle sleeve connector, gas injection wellhead fluid monitoring pipeline and system

A monitoring system and connector technology, which are applied in the fields of production fluids, wellbore/well components, wellbore/well valve devices, etc., can solve the problem of lack of effective means for metering monitoring, reduce flow monitoring costs, and improve regulation. Efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

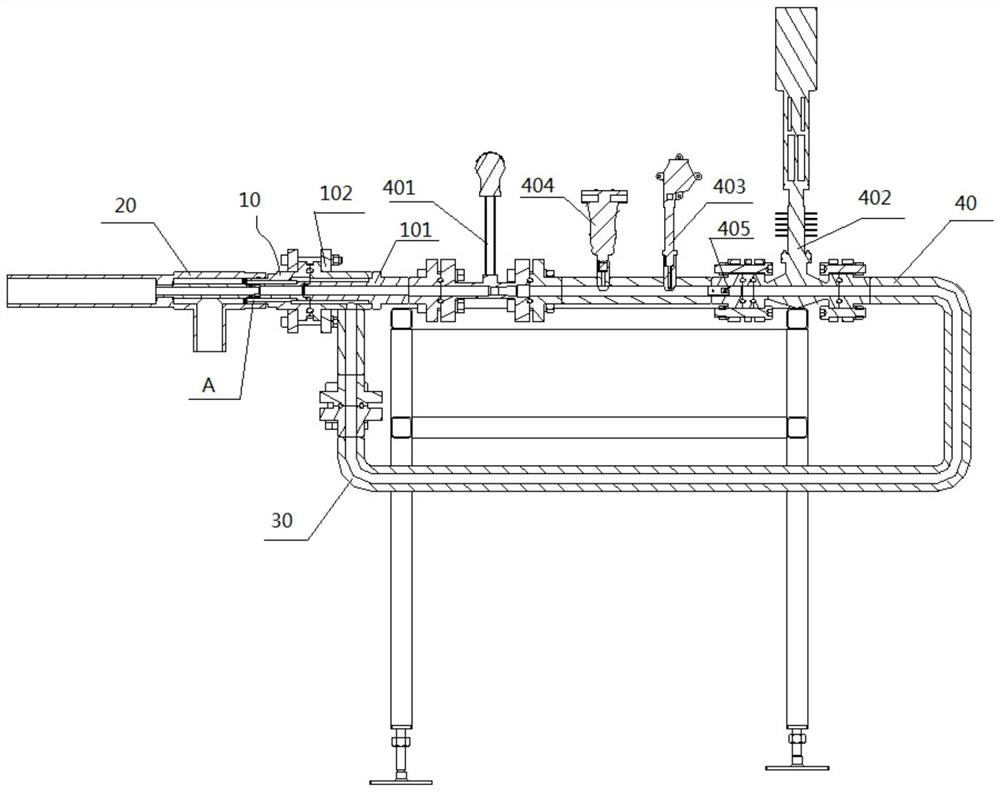

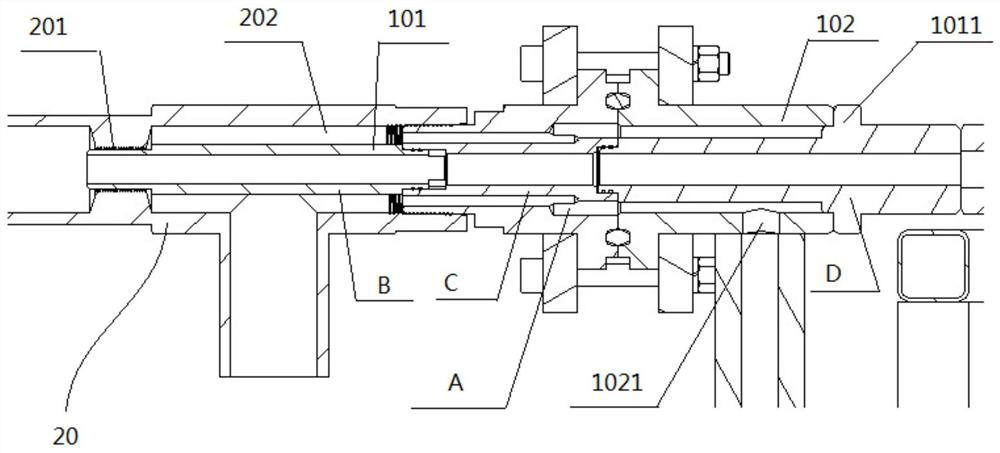

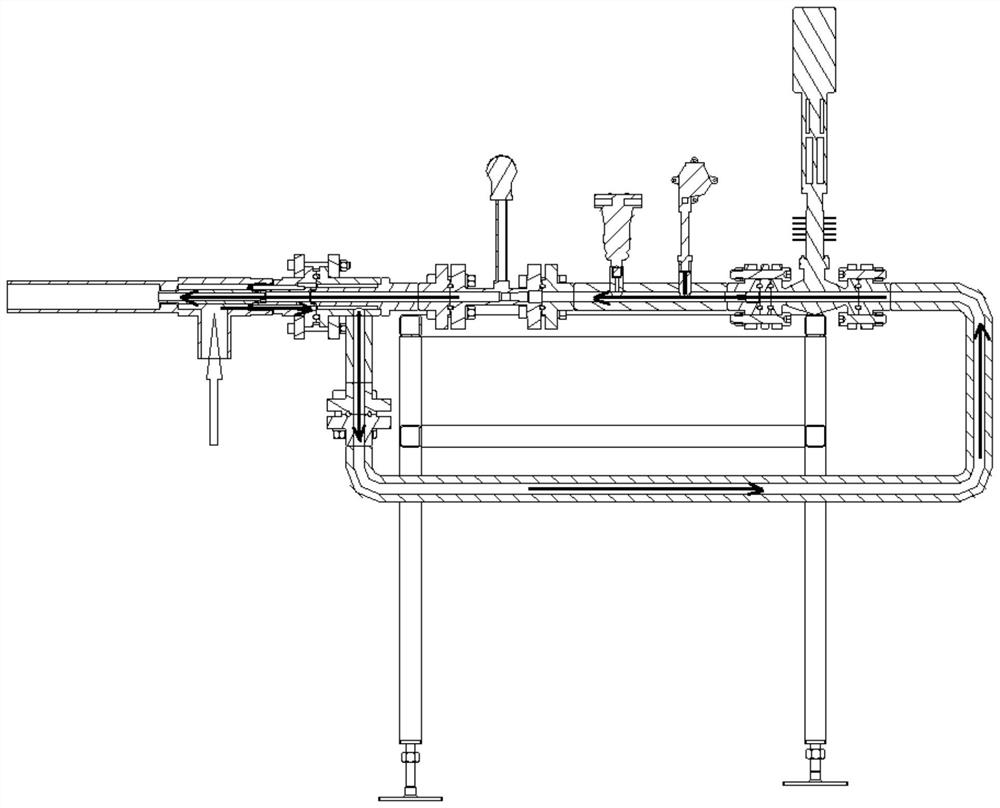

[0037] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

[0038] In order to realize injection with a limited flow rate when injecting into the wellhead, the present invention effectively utilizes the three-way structure of the nozzle sleeve, so that after the fluid is injected into the nozzle sleeve, the fluid is introduced into the fluid monitoring pipeline to monitor the fluid and adjust it to an appropriate value Then inject heavy oil multi-element thermal fluid thermal recovery gas injection wellhead through the nozzle sleeve to form a fluid closed-loop monitoring pipeline, and divide the cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com