Preparation method of HAp blended silver and copper antibacterial composite coating

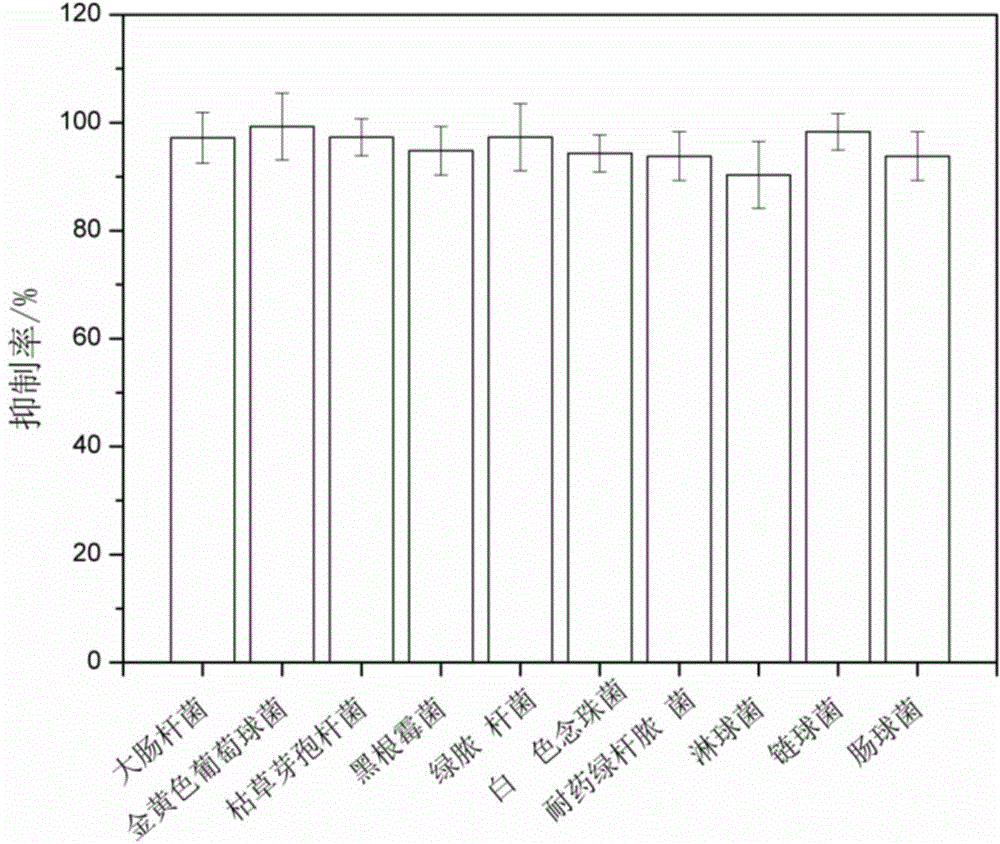

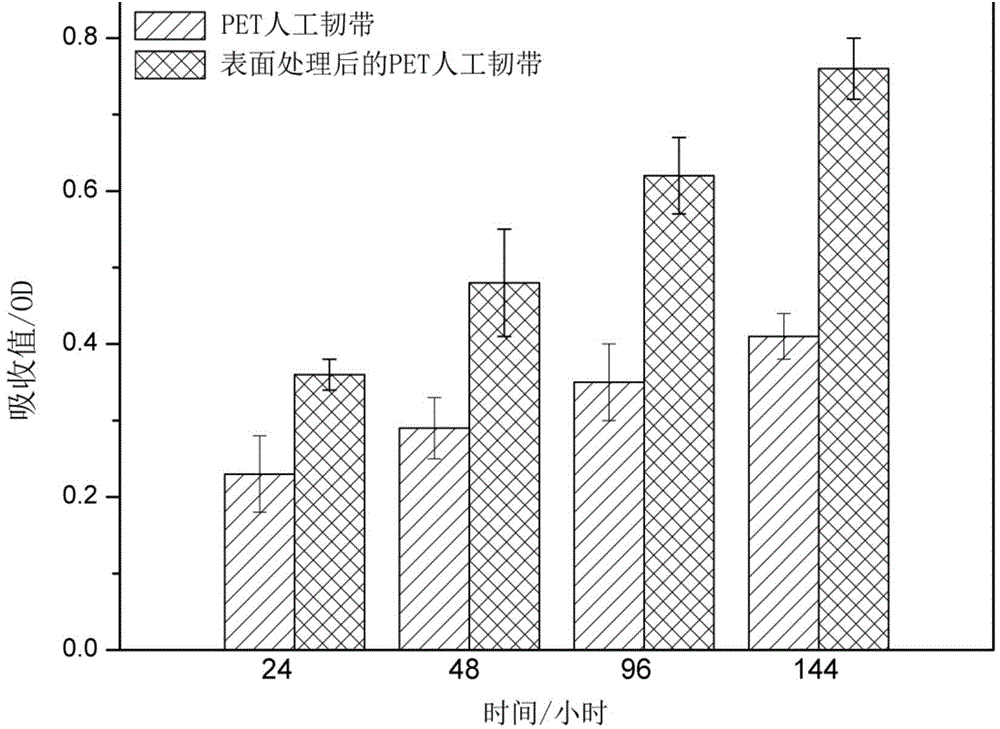

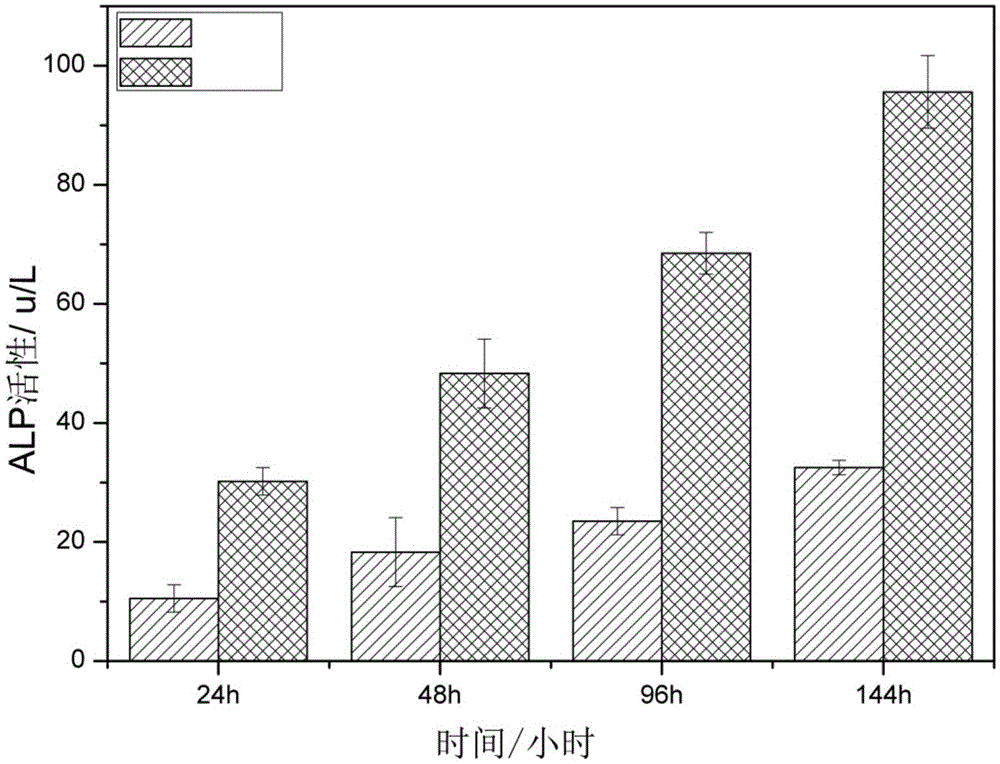

A technology of composite coating and antibacterial agent, which is applied in the field of preparation of HAp mixed with silver and copper antibacterial agent composite coating, can solve the problems of literature and patent reports that do not use silver and copper antibacterial agent to modify bionic artificial ligament, etc. Achieve the effects of promoting clinical application, improving osseointegration ability, and reducing synovitis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Present embodiment relates to a kind of preparation method of HAp blending silver and copper antibacterial agent composite coating, described method comprises the steps:

[0034] The first step is the pretreatment of the artificial ligament. The surface of the artificial ligament is ultrasonically cleaned for 30 minutes, rubbed repeatedly with steel grit with a surface roughness of 50um for 5 times, rinsed with distilled water for 3 times, and dried in vacuum;

[0035] In the second step, with water as solvent, 1 ml of 25 mmol / L CaSO 4 , Ag source (silver nitrate: silver bromide = 1:1 mixed) and CuSO 4 and 5 ml of 25 mg / L bovine gelatin solution, adjust the pH value to 8, and stir for 5 minutes at 25°C, then soak the artificial ligament in this mixture, and stir for 30 minutes to make the free Ca and Ag in the system Fully combined with copper ions and amino residues in gelatin;

[0036] The third step is to take out the artificial ligament, blot dry with filter paper...

Embodiment 2

[0042] Present embodiment relates to a kind of preparation method of HAp blending silver and copper antibacterial agent composite coating, described method comprises the steps:

[0043] The first step is the pretreatment of the artificial ligament. The surface of the artificial ligament is ultrasonically cleaned for 30 minutes, rubbed repeatedly with steel grit with a surface roughness of 50um for 5 times, rinsed with distilled water for 3 times, and dried in vacuum;

[0044] In the second step, using water as solvent, 5 ml of 15 mmol / L CaCO 3 , AgNO 3 and CuSO 4 and 5 ml of 25 mg / L porcine gelatin solution, adjust the pH value to 7, and stir for 5 minutes at 25°C, then soak the artificial ligament in this mixture, and stir for 45 minutes to make the free Ca and Ag in the system Fully combined with copper ions and amino residues in gelatin;

[0045] The third step is to take out the artificial ligament, blot it dry with filter paper, and put in 10 ml of 50 mmol / L freshly prep...

Embodiment 3

[0048] Present embodiment relates to a kind of preparation method of HAp blending silver and copper antibacterial agent composite coating, described method comprises the steps:

[0049] The first step is the pretreatment of the artificial ligament. The surface of the artificial ligament is ultrasonically cleaned for 30 minutes, rubbed repeatedly with steel grit with a surface roughness of 25-50um for 10 times, rinsed with distilled water for 3 times, and dried in vacuum;

[0050] In the second step, using water as solvent, 5 ml of 15 mmol / L CaCO 3 , AgNO 3 Mix with copper source (copper nitrate: copper sulfate = 2:1 mixture) and 5 ml of 25 mg / L rabbit source gelatin solution, adjust the pH value to 8, stir at 25 ° C for 5 minutes, and then soak the artificial ligament in this mix In the solution, stir and react for 15 minutes, so that the free Ca and Ag and copper ions in the system can fully combine with the amino residues in the gelatin;

[0051] The third step is to take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com