Preparation method of monodispersed nano-calcium carbonate with low surface energy

A technology of nano-calcium carbonate and low surface energy, which is applied in nanotechnology, calcium carbonate/strontium/barium, nanotechnology, etc. for materials and surface science, and can solve the problems of increasing costs, affecting the performance of nano-calcium carbonate, and high surface energy. problems, achieve the effects of reducing specific surface energy, inhibiting re-aggregation, and inhibiting crystal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of low surface energy monodisperse nano-calcium carbonate, comprising the following steps:

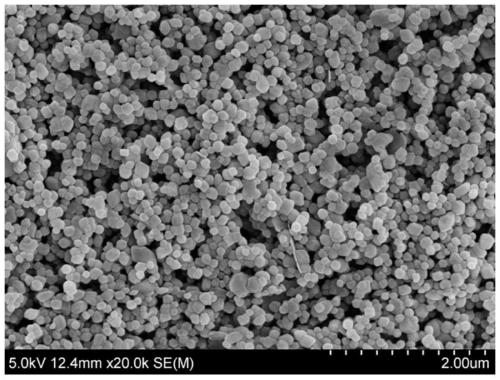

[0032] S1. Prepare nano-calcium carbonate cooked pulp. Nano-calcium carbonate cooked pulp was prepared by intermittent bubbling carbonization method, the solid content of the raw pulp was 9%, the carbonization starting temperature was 20°C, and CO 2 The content is 35%; the carbonization is completed until the slurry pH=7.0. After carbonization, the product obtained is in the form of a chain aggregate or a nearly spherical granular aggregate, the primary grain diameter is 50-100nm, and the aggregate is 3-5μm.

[0033] S2. Adding an aging agent to the cooked nano-calcium carbonate slurry prepared in S1, the aging temperature is 80° C., and the aging time is 24 hours to obtain an aged suspension of nano-calcium carbonate.

[0034] The aging agent is 1% ammonia water, 0.5% urea and 0.5% citric acid, and the amount of aging agent is calculated according to the ...

Embodiment 2

[0038] A preparation method of low surface energy monodisperse nano-calcium carbonate, comprising the following steps:

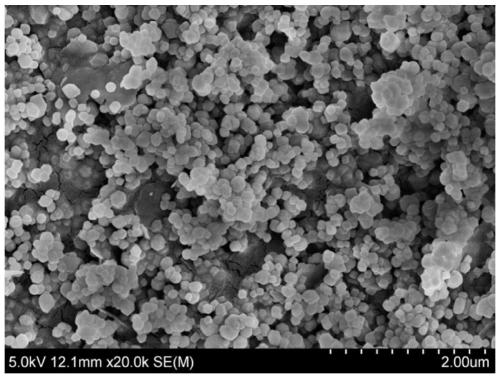

[0039] S1. Prepare nano-calcium carbonate cooked pulp. Adopt Venturi carbonization method to prepare nano-calcium carbonate cooked pulp, under room temperature, add the calcium hydroxide suspension that concentration is 8% in the carbonization tower, pass into carbon dioxide gas (CO 2 content 30%) to the pH of the reaction slurry=6.5 to obtain the cooked slurry of nano-calcium carbonate.

[0040] S2. Adding an aging agent to the cooked nano-calcium carbonate slurry prepared in S1, the aging temperature is 100° C., and the aging time is 12 hours to obtain an aged suspension of nano-calcium carbonate.

[0041] The seasoning agent is hydrochloric acid. The dosage of the aging agent is 0.5% of the mass of calcium carbonate on a dry basis.

[0042] S3. Adding a surface treatment agent to the aged suspension of nano-calcium carbonate prepared in S2 for surface ...

Embodiment 3

[0045] A preparation method of low surface energy monodisperse nano-calcium carbonate, comprising the following steps:

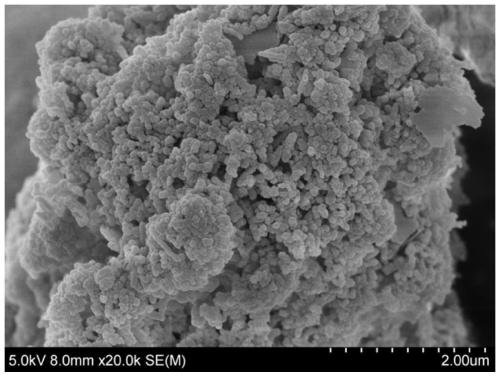

[0046] S1. Prepare nano-calcium carbonate cooked pulp. Nano-calcium carbonate cooked pulp was prepared by high-gravity carbonization method, the solid content of the raw pulp was 12%, and the carbonization starting temperature was room temperature, CO 2 Content 29%. When the reaction slurry reaches a pH of 6.0, the carbonization is stopped to obtain a cooked slurry of nano-calcium carbonate.

[0047] S2. Adding an aging agent to the cooked nano-calcium carbonate slurry prepared in S1, the aging temperature is 80° C., and the aging time is 48 hours to obtain an aged suspension of nano-calcium carbonate.

[0048] Described aging agent is acetic acid, and the consumption of aging agent is 3% of calcium carbonate dry weight.

[0049] S3. Adding a surface treatment agent to the aged suspension of nano-calcium carbonate prepared in S2 for surface treatment, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com