Method for modifying nano hydroxyapatite, nano hydroxyapatite/polylactic acid compound material and preparation method of nano hydroxyapatite/polylactic acid compound material

A technology of nano-hydroxyapatite and composite materials, which is applied in the preparation of nano-hydroxyapatite/polylactic acid composite materials and the modification of nano-hydroxyapatite, which can solve the problem of high reaction temperature and reduced purity of hydroxyapatite , high equipment and process requirements, etc., to achieve good dispersion performance, improve interface compatibility, and short process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

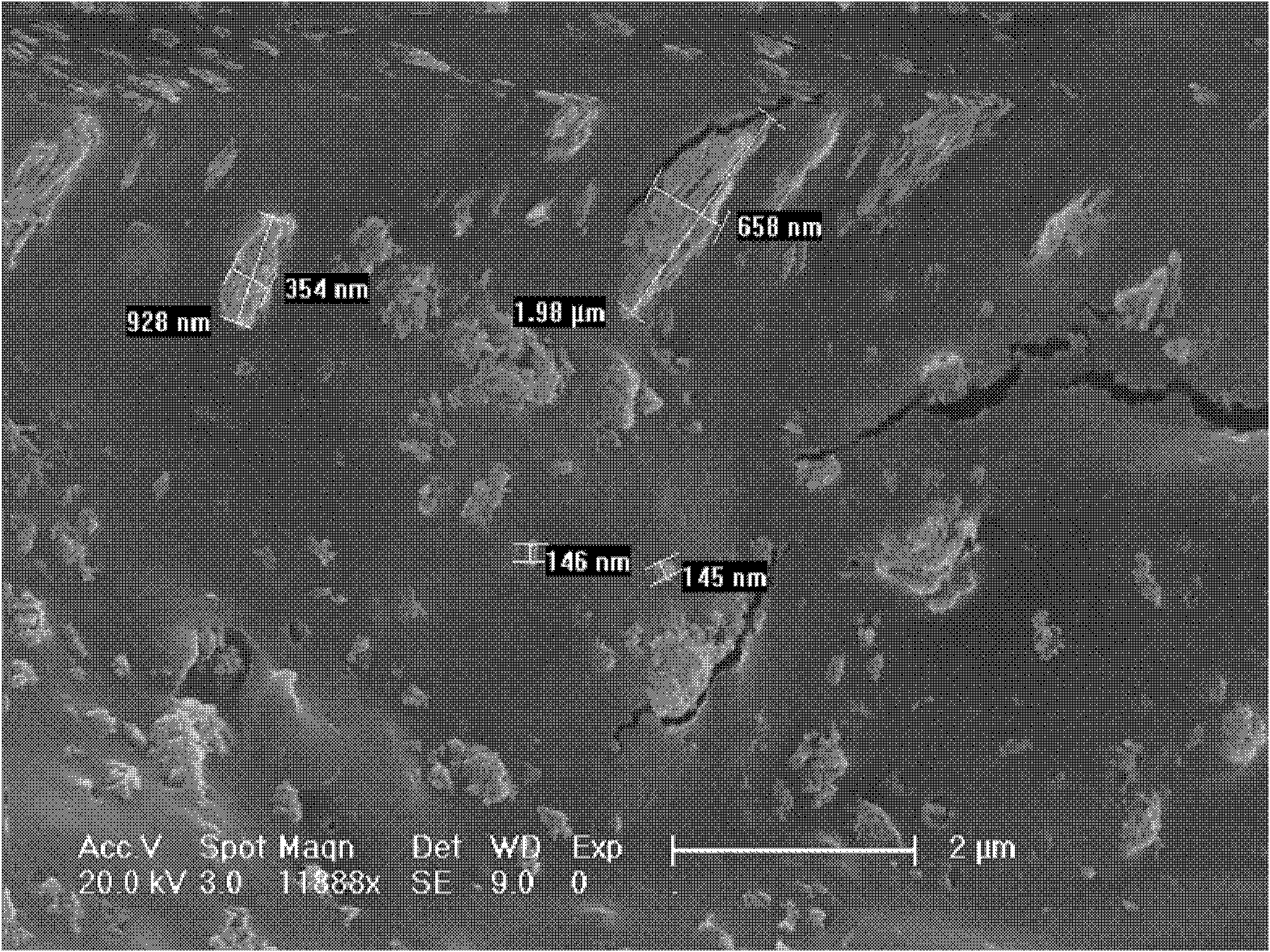

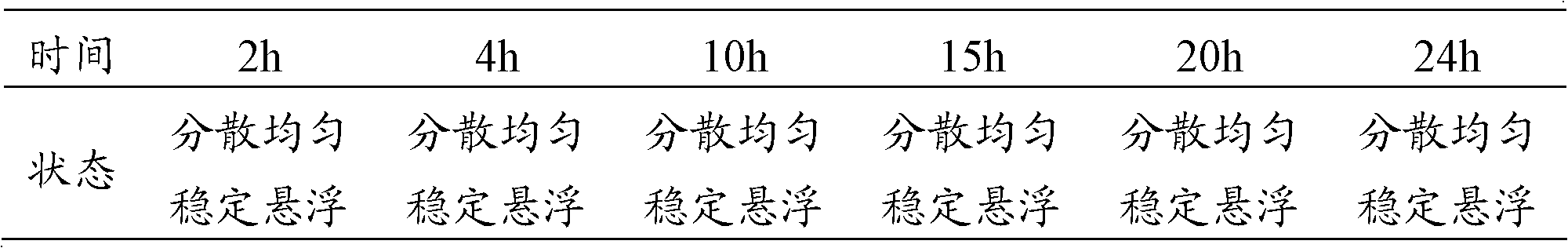

[0063] The modification of embodiment 1 nano-hydroxyapatite

[0064] 20g of oligomeric lactic acid with a number average molecular weight of 600 is heated and dissolved in 300mL of acetone to obtain a oligomeric lactic acid acetone solution; 75g of nano-hydroxyapatite hydrosol is added to the oligomeric lactic acid-acetone solution, and the nano-hydroxyapatite The mass of water in the hydrosol is 2.5 times the mass of nano-hydroxyapatite. After ultrasonic treatment for 40 minutes, add 300 mL of distilled water. After filtration, the obtained filtrate is dried under reduced pressure at 40°C for 72 hours to obtain nano-hydroxyapatite and oligomers. a mixture of lactic acids;

[0065] Dissolve the mixture of nano-hydroxyapatite and oligomeric lactic acid in 100 mL of chloroform, sonicate for 15 minutes, then centrifuge at high speed for 15 minutes, repeat the operation 3 times to remove excess oligomeric lactic acid, and dry under reduced pressure at 40°C for 72 hours to obtain o...

Embodiment 2

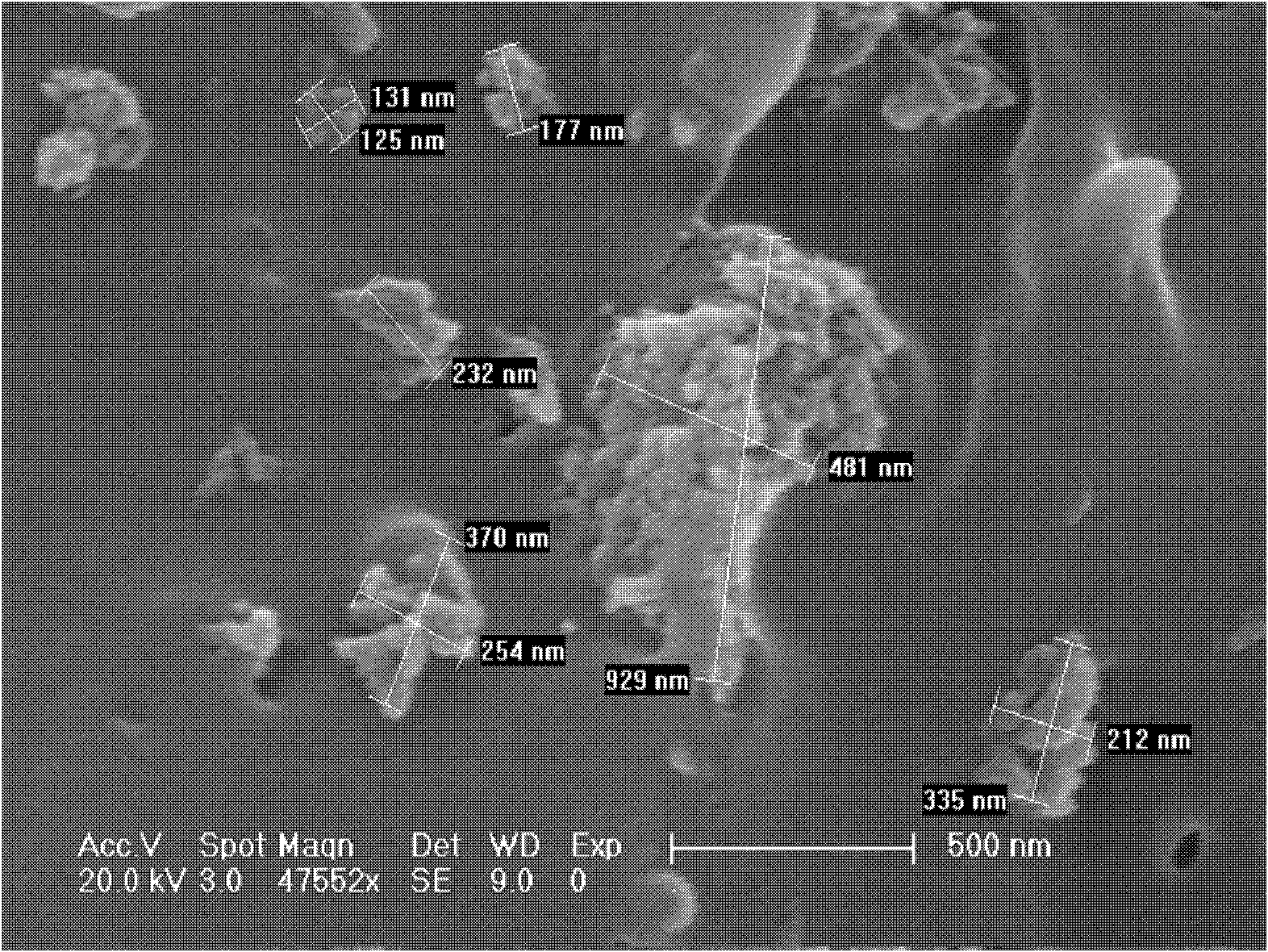

[0071] Modification of embodiment 2 nanometer hydroxyapatite

[0072] 20g of oligomeric lactic acid with a number average molecular weight of 2300 is heated and dissolved in 300mL of acetone to obtain a oligomeric lactic acid acetone solution; 75g of nano-hydroxyapatite hydrosol is added to the oligomeric lactic acid-acetone solution, and the nano-hydroxyapatite The mass of water in the hydrosol is 2.5 times the mass of nano-hydroxyapatite. After ultrasonic treatment for 40 minutes, 300 mL of distilled water is added, and after filtration, the obtained filtrate is dried under reduced pressure at 60°C for 72 hours to obtain nano-hydroxyapatite and oligomers. a mixture of lactic acids;

[0073] Dissolve the mixture of nano-hydroxyapatite and oligomeric lactic acid in 100 mL of chloroform, sonicate for 15 minutes, then centrifuge at high speed for 15 minutes, repeat the operation 3 times to remove excess oligomeric lactic acid, and dry under reduced pressure at 40°C for 72 hours ...

Embodiment 3

[0076] Modification of embodiment 3 nanometer hydroxyapatite

[0077] 20g of oligomeric lactic acid with a number average molecular weight of 4700 was heated and dissolved in 300mL of acetone to obtain a oligomeric lactic acid acetone solution; 75g of nano-hydroxyapatite hydrosol was added to the oligomeric lactic acid-acetone solution, and the nano-hydroxyapatite The mass of water in the hydrosol is 2.5 times that of nano-hydroxyapatite. After ultrasonic treatment for 40 minutes, add 300 mL of distilled water. After filtration, dry the obtained filtrate at 80°C for 72 hours under reduced pressure to obtain nano-hydroxyapatite and oligomers. a mixture of lactic acids;

[0078] Dissolve the mixture of nano-hydroxyapatite and oligomeric lactic acid in 100 mL of chloroform, sonicate for 15 minutes, then centrifuge at high speed for 15 minutes, repeat the operation 3 times to remove excess oligomeric lactic acid, and dry under reduced pressure at 40°C for 72 hours to obtain oligom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com