Carbon nano tube composite film and preparation method thereof

A technology of carbon nanotube composite and carbon nanotubes, which is applied in the direction of carbon compounds, nanotechnology, nanotechnology, etc., can solve the problems of complexity, weak non-covalent interaction, time-consuming processing, etc., and achieve low equipment requirements, Mild reaction conditions and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

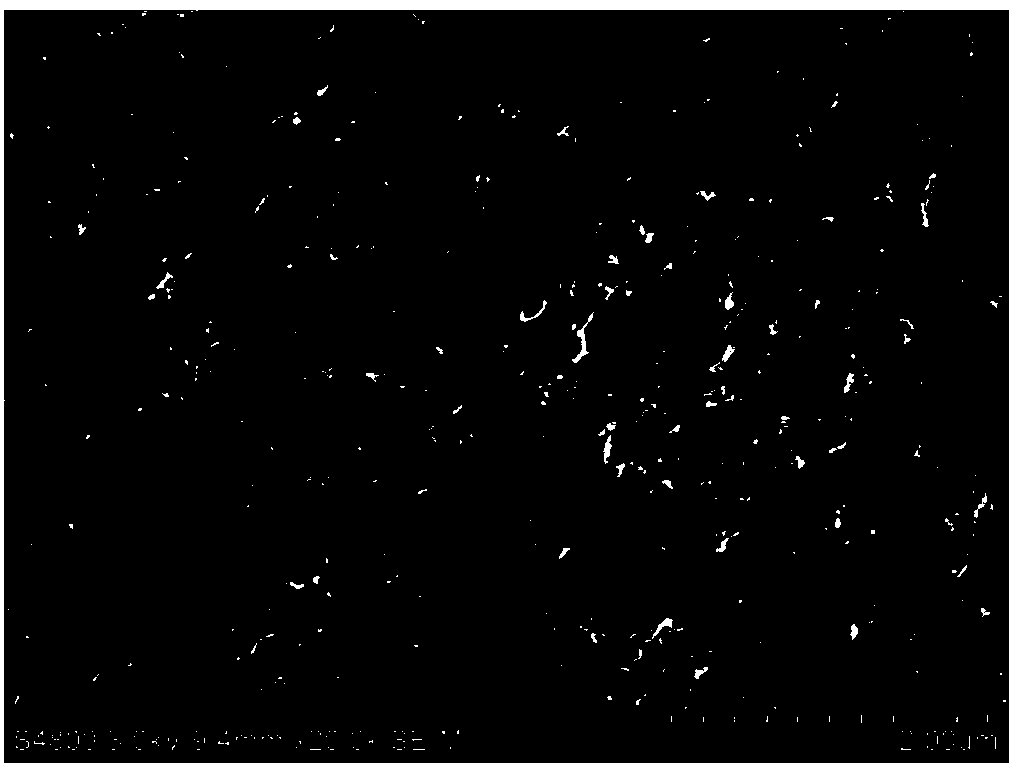

Image

Examples

Embodiment 1

[0051] (1) Ultrasonically disperse carbon nanotubes (1mg / mL) in a solution of 10mM tris-hydrochloric acid at pH=8.5, then add one part per ten thousand of dopamine and stir for 48 hours to obtain polydopamine-modified Dispersion of carbon nanotubes (CNTPDA);

[0052] (2) Dissolve polyethyleneimine (PEI) in deionized water (adjust the pH to 9 with hydrochloric acid) to prepare a 2 mg / mL PEI solution;

[0053] (3) Soak the cleaned silicon wafer completely in 2mg / mL PEI solution, take it out after 15 minutes, wash it with deionized water, and then dry it with nitrogen;

[0054] (4) Soak the silicon wafer obtained in step (3) completely in the CNTPDA dispersion, take it out after 15 minutes, wash it with deionized water, and then dry it with nitrogen;

[0055] (5) After repeating steps (3) to (4) 20 times, take out the silicon wafer, wash it with deionized water and blow it dry with nitrogen, then soak the silicon wafer in 2 mg / mL PEI solution for 15 minutes, then use After wash...

Embodiment 2

[0059] (1) Ultrasonically disperse carbon nanotubes (2 mg / mL) in a solution of 10 mM tris-hydrochloric acid at pH = 8.5, then add one part per ten thousand of dopamine and stir for 16 hours to obtain polydopamine-modified Dispersion of carbon nanotubes (CNTPDA);

[0060] (2) Dissolve polyethyleneimine (PEI) in deionized water (adjust the pH to 9 with hydrochloric acid) to prepare a 0.5 mg / mL PEI solution;

[0061] (3) Coat the surface of the cleaned silicon wafer with a layer of acetone solution of cellulose acetate; wait for the acetone to volatilize naturally for later use.

[0062] (4) Soak the silicon wafer pre-coated with cellulose acetate in 0.5 mg / mL PEI solution, take it out after 15 minutes, wash it with deionized water, and then dry it with nitrogen;

[0063] (5) Soak the silicon wafer obtained in step (3) completely in the CNTPDA dispersion, take it out after 15 minutes, wash it with deionized water, and then dry it with nitrogen;

[0064] (6) After repeating step...

Embodiment 3

[0070] (1) Ultrasonically disperse carbon nanotubes (1mg / mL) in a solution of 10mM tris-hydrochloric acid at pH=8.5, then add one part per ten thousand of dopamine and stir for 48 hours to obtain polydopamine-modified Dispersion of carbon nanotubes (CNTPDA);

[0071] (2) Dissolve polyethyleneimine (PEI) in deionized water (adjust the pH to 9 with hydrochloric acid) to prepare a 2 mg / mL PEI solution;

[0072] (3) Soak the cleaned silicon wafer completely in 2mg / mL PEI solution, take it out after 15 minutes, wash it with deionized water with pH=9, and then dry it with nitrogen;

[0073] (4) Soak the silicon wafer obtained in step (3) completely in the CNTPDA dispersion, take it out after 15 minutes, wash it with deionized water, and then dry it with nitrogen;

[0074] (5) After repeating steps (3) to (4) 20 times, take out the silicon wafer, wash it with deionized water, and then dry it with nitrogen, then soak the silicon wafer in 2 mg / mL PEI solution for 15 minutes, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com