Modified carbon fiber reinforced resin-based composite material and preparation method thereof

A fiber-reinforced resin and composite material technology, applied in the field of modified carbon fiber-reinforced resin-based composite materials and their preparation, can solve the problems of interface coordination and insufficient strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

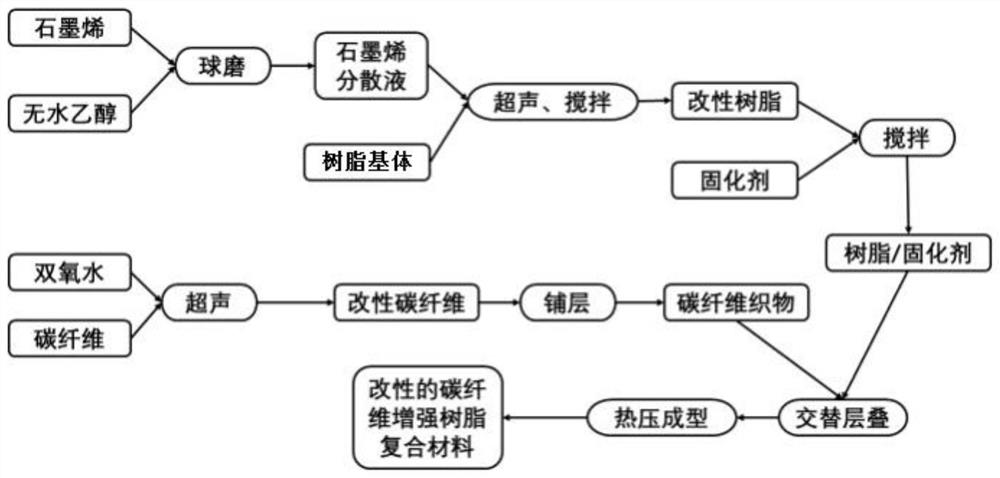

[0022] like figure 1 As shown, the invention provides a kind of preparation method of modified carbon fiber reinforced resin matrix composite material, comprises the following steps:

[0023] mixing the graphene dispersion with the resin matrix to modify it to obtain a modified resin matrix;

[0024] Immerse the carbon fiber in the hydrogen peroxide solution and perform ultrasonic treatment to obtain the modified carbon fiber;

[0025] laying up the modified carbon fiber to obtain a carbon fiber fabric;

[0026] The modified resin matrix and the curing agent are mixed, and the obtained modified resin matrix-curing agent mixture and the carbon fiber fabric are alternately laminated and hot-pressed in sequence to obtain the modified carbon fiber reinforced resin matrix composite material.

[0027] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0028] In the ...

Embodiment 1

[0050] Commercially available graphene sheet and dehydrated alcohol are placed in the ball mill tank of planetary ball mill, carry out ball milling 12h, the graphene (graphene particle diameter 100nm, thickness 2~3nm) that ball mills is redispersed in dehydrated alcohol, Be made into the graphene dispersion liquid that concentration is 1mg / mL;

[0051] The graphene dispersion is added into the epoxy resin according to the ratio of 0.2% by mass fraction, then ultrasonicated for 30min, then stirred for 30min (rotational speed is 1000rpm), then vacuum-dried at 80°C for 24h to remove the epoxy resin. ethanol and air bubbles to obtain a modified resin matrix;

[0052] Use deionized water to dilute the hydrogen peroxide solution to a hydrogen peroxide solution with a mass fraction of 5%, cut the carbon fiber to 30mm (length) × 30mm (width), immerse it in the hydrogen peroxide solution, and ultrasonically treat it for 30min with a power of 150W. Ultrasonic cleaning with deionized wa...

Embodiment 2

[0058] The difference between this embodiment and embodiment 1 is that the graphene dispersion is added to the epoxy resin at a mass fraction of 0.3%.

[0059] The test was carried out according to the method of Example 1. The results showed that the modified carbon fiber reinforced resin matrix composite had a viscosity of 4138.22mPa·s, a bending strength of 737.16MPa, a tensile strength of 2.98GPa, and an interlaminar shear strength of 39.52MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com