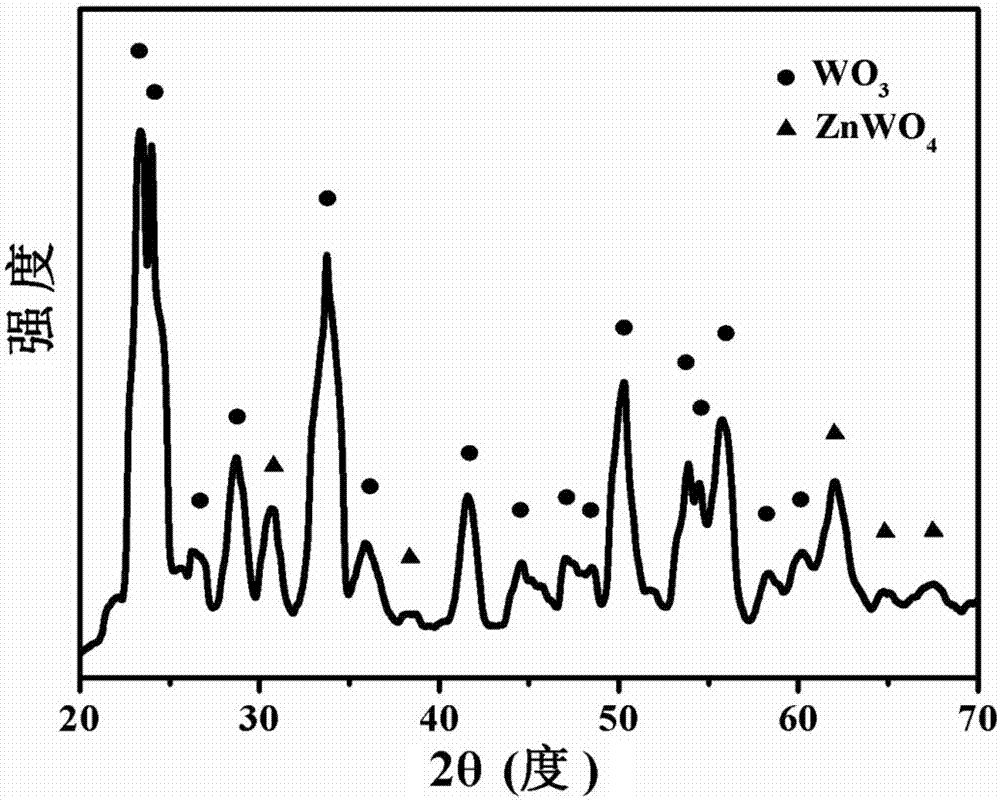

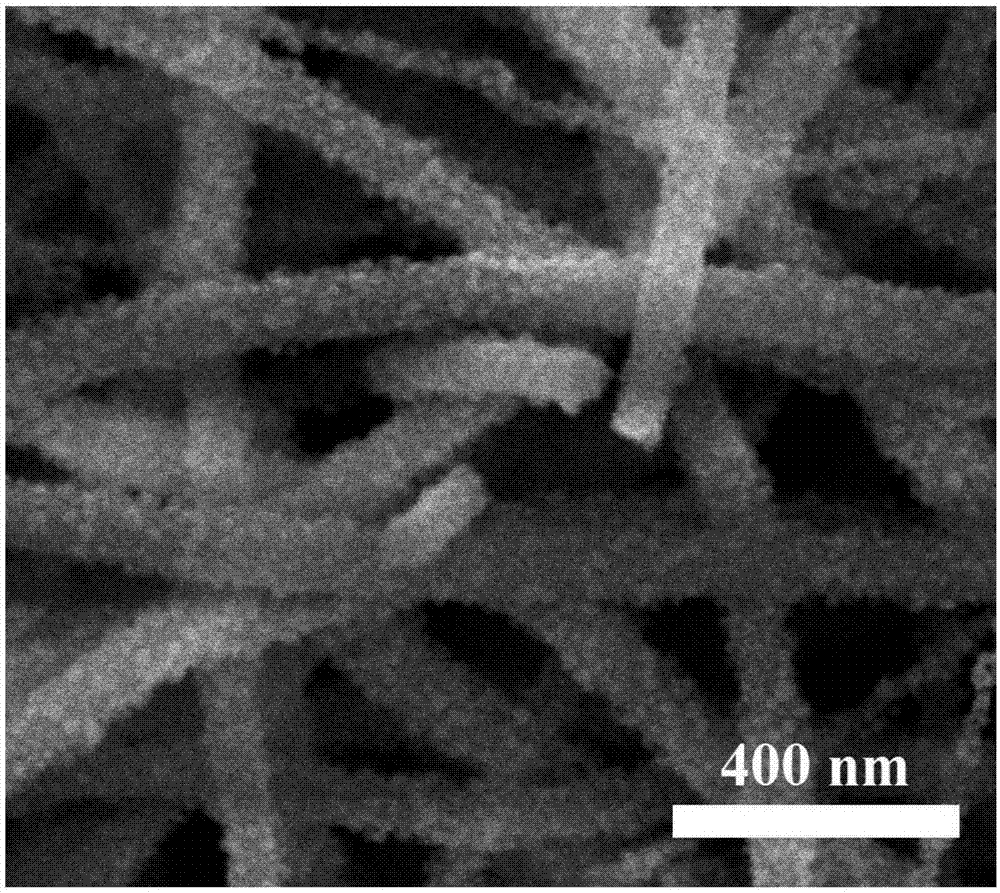

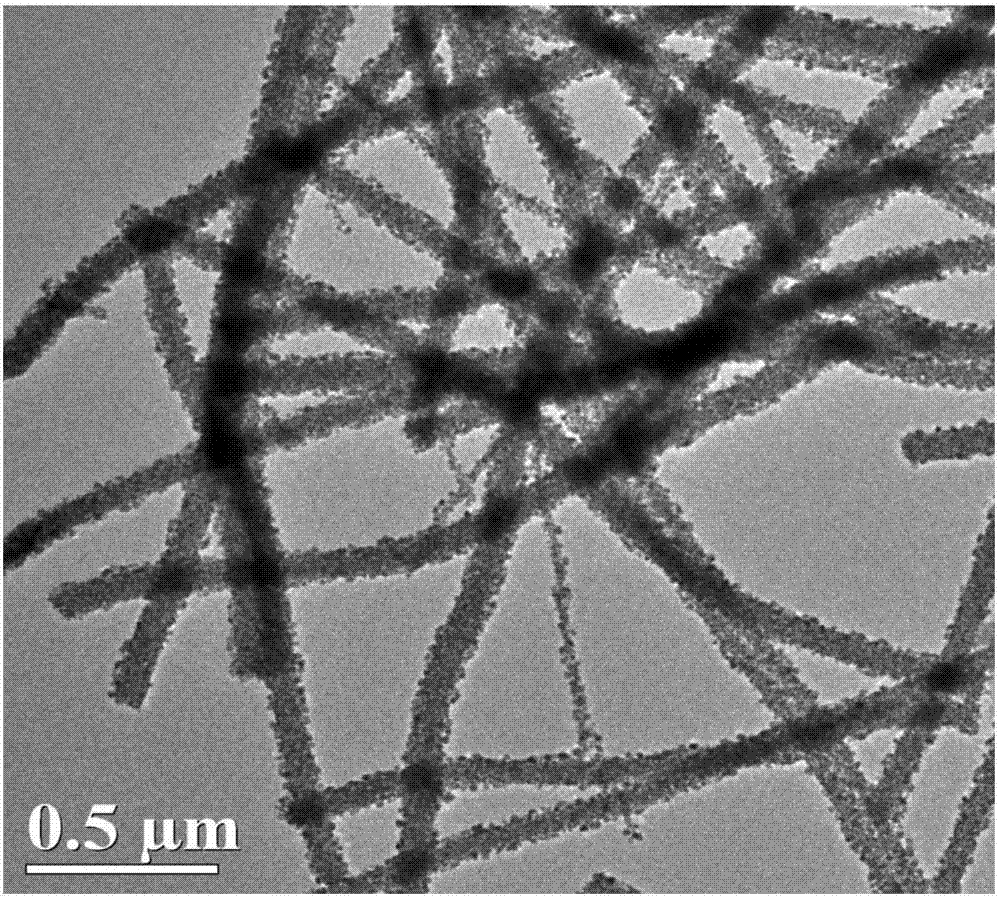

Preparation method of WO3/ZnWO4 composite micro-nano fiber and product of WO3/ZnWO4 composite micro-nano fiber

A micro-nano fiber, a certain amount of technology, applied in the direction of nanotechnology, nanotechnology, fiber processing, etc., to achieve the effect of strong operability, expansion of research fields, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Add 0.7419 g of zinc nitrate hexahydrate (Zn(NO 3 ) 2 ∙6H 2 O) and 0.8188 g of 2-methylimidazole were respectively dissolved in 50.0 mL of methanol solvent, stirred to obtain a transparent solution, mixed evenly, stirred for 1 h, left to stand for 24 h, centrifuged and washed with methanol solvent for 3 times, and then evaporated Dried naturally in a dish to obtain the Zif-8 product;

[0034] (2) Dissolve 1.0 mL of polyethylene glycol 200, 1.0 mL of formamide, and 0.0136 g of Zif-8 in 4.0 mL of Tris-HCl buffer in sequence, and stir to obtain a transparent solution 1;

[0035] (3) Dissolve 0.3000 g of tungstic acid in 6.0 mL of ammonia water, heat and stir to obtain a transparent solution 2;

[0036] (4) Dissolve 1.5540 g of PVP in a mixed solvent of 5.0 mL of absolute ethanol and 2.0 mL of deionized water, and stir to obtain a transparent solution 3;

[0037] (5) According to the volume ratio of 1:1:1.2, solution 1 and solution 2 were added dropwise to solution ...

Embodiment 2

[0041] (1) Add 0.7419 g of Zn(NO 3 ) 2 ∙6H 2 O and 0.7430 g of 2-methylimidazole were respectively dissolved in 46 mL of methanol solvent, stirred to obtain a transparent solution, mixed evenly, stirred for 2 h, left to stand for 24 h, washed with methanol solvent for 3 times, and placed in an evaporating dish Dry naturally in medium to obtain Zif-8 product;

[0042] (2) Dissolve 1.0 mL of polyethylene glycol 200, 1.2 mL of formamide, and 0.0075 g of Zif-8 in 3.8 mL of Tris-HCl buffer in sequence, and stir to obtain a transparent solution 1;

[0043] (3) Dissolve 0.2325 g of tungstic acid in 6.0 mL of ammonia water, heat and stir to obtain a transparent solution 2;

[0044] (4) Dissolve 1.2850 g of PVP in a mixed solvent of 5.0 mL of absolute ethanol and 2.0 mL of deionized water, and stir to obtain a transparent solution 3;

[0045] (5) According to the volume ratio of 1:1:1, solution 1 and solution 2 were added dropwise to solution 3 at a rate of 0.3 mL / min. After the th...

Embodiment 3

[0048] (1) Add 0.7419 g of Zn(NO 3 ) 2 ∙6H 2 O and 0.8915 g of 2-methylimidazole were respectively dissolved in 48 mL of methanol solvent, stirred to obtain a transparent solution, mixed evenly and stirred for 1 h, after standing for 24 h, washed with methanol solvent for 3 times, placed in an evaporating dish Dry naturally in medium to obtain Zif-8 product;

[0049] (2) Dissolve 1.0 mL of polyethylene glycol 200, 1.5 mL of formamide, and 0.1771 g of Zif-8 in 3.5 mL of Tris-HCl buffer in sequence, and stir to obtain a transparent solution 1;

[0050] (3) Dissolve 0.3600 g of tungstic acid in 6.0 mL of ammonia water, heat and stir to obtain a transparent solution 2;

[0051] (4) Dissolve 1.7871 g of PVP in a mixed solvent of 5.0 mL of absolute ethanol and 2.0 mL of deionized water, and stir to obtain a transparent solution 3;

[0052] (5) According to the volume ratio of 1:1:1.4, solution 1 and solution 2 were added dropwise to solution 3 at a rate of 0.5 mL / min. After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com