Electrically conductive polymer-graphene composite electrochromic film and preparation method thereof

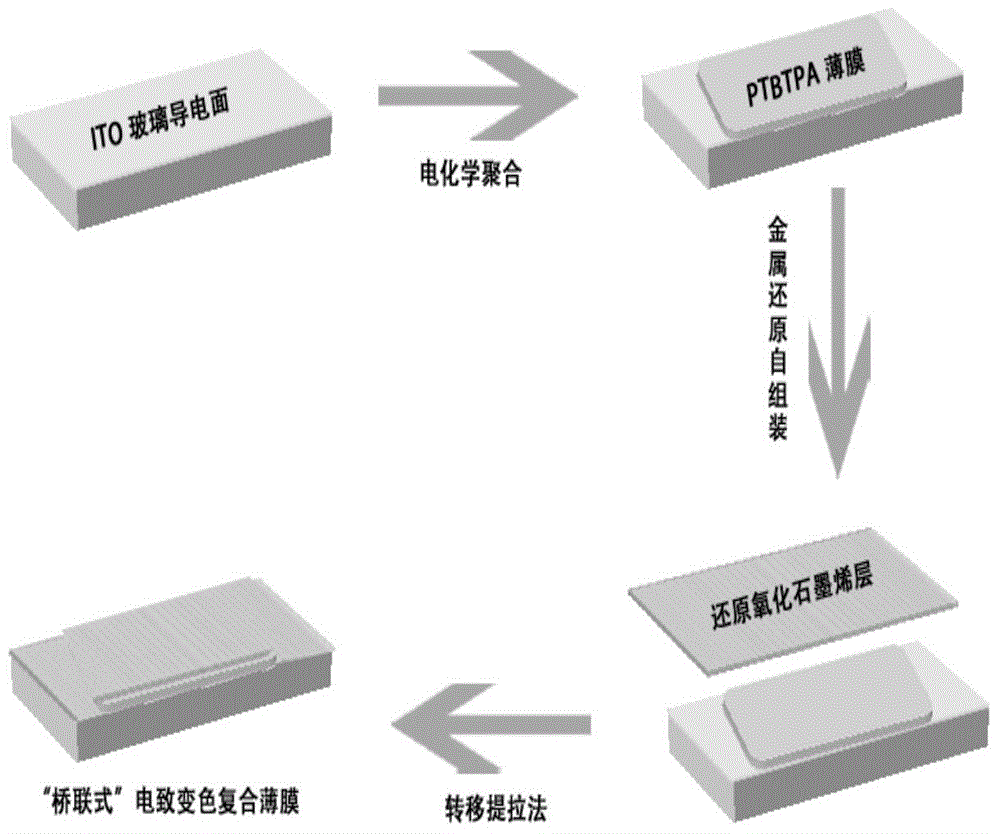

A technology of conductive polymer and graphene film, which is applied in the field of composite electrochromic film and its preparation, can solve the problems of poor electrode conductivity, no change in response time and contrast, and low quality of composite film, so as to achieve easy transfer and simple operation , the effect of controllable film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The conductive polymer monomer is 4,4',4"-tris(bithiophene)triphenylamine (TBTPA)

[0034] (1) Preparation of conductive polymer film: Mix 50ml of electrolytic solvent acetonitrile and dichloromethane (volume ratio 3:7), monomer (0.0276g, 0.75mM) and supporting electrolyte tetrabutylammonium perchlorate (TBAP , 1.71g, 0.1M) were uniformly mixed and prepared as an electrolyte, and then added to a three-electrode electrolytic cell, wherein the working electrode was an ITO glass electrode (its size was 0.9×4cm), the auxiliary electrode was a platinum electrode, and the reference electrode was silver - Silver chloride electrodes. Under the condition of 1.2V, the constant potential method is used to carry out the polymerization reaction. When the power consumption of the polymerization reaches 0.06C, the polymerization ends, and a layer of blue polymer film is deposited on the surface of the working electrode ITO conductive glass. When the potential is controlled to -0.6V, ...

Embodiment 2

[0038] The monomer is replaced by 1,4-di(3-thienyl)benzene (DTB)

[0039] (1) Preparation of conductive polymer film: 50ml of electrolytic solvent dichloromethane, monomer (0.0242g, 2mM) and supporting electrolyte tetrabutylammonium perchlorate (TBAP, 1.71g, 0.1M) were evenly mixed to prepare electrolyte , and then added to a three-electrode electrolytic cell, wherein the working electrode is ITO glass (its size is 0.9 × 4cm), the auxiliary electrode is a platinum electrode, and the reference electrode is a silver-silver chloride electrode. Under the condition of polymerization potential 1.3V, the polymerization reaction is carried out by constant potential method. When the power consumption of polymerization reaches 0.04C, the polymerization ends, and a layer of yellow polymer film is deposited on the surface of the working electrode ITO glass electrode. When the potential is controlled to -0.6V , dedoped the working electrode after the polymerization reaction for 100s, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com