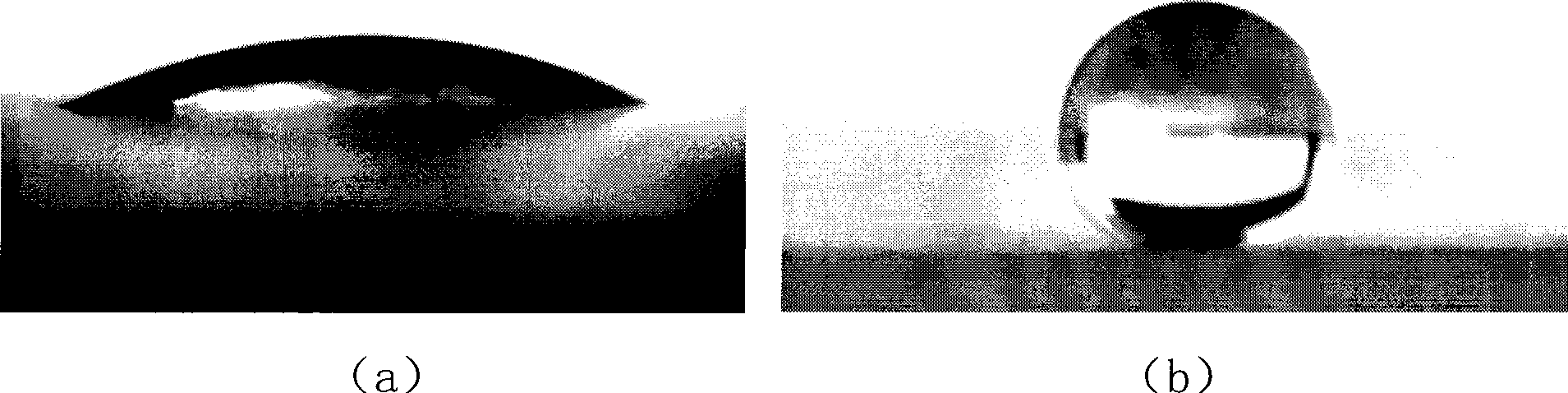

Method for preparing porcelain insulator surface super-hydrophobic coating

A ceramic insulator and super-hydrophobic technology, which is applied in the field of preparation of super-hydrophobic interfaces, can solve the problems of unpublished reports, complex preparation methods and high costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Using tetraethyl orthosilicate (TEOS) as the precursor and absolute ethanol as the flux, after mixing according to the mass ratio of tetraethyl orthosilicate: absolute ethanol: ammonia water = 1:20:1, at a temperature of 50°C Stir down, prepare silica sol;

[0017] (2) Silica sol was modified by adding 8wt% of N-β-aminoethyl-γ-aminopropylmethyldimethoxysilane and stirred at room temperature. Then carry out vacuum defoaming treatment;

[0018] (3) Clean the surface of the porcelain insulator, dip it in a methanol solution containing 3wt% N-β-aminoethyl-γ-aminopropylmethyldimethoxysilane for 5 minutes, take it out and dry it naturally;

[0019] (4) Put the porcelain insulator in the modified silica sol for pulling coating, form a coating on the surface of the porcelain insulator, dry it naturally and put it in an oven for heat treatment at 110 degrees Celsius;

[0020] (5) Add curing agent DACH (1,2, diaminocyclohexane) to the addition-type RTV liquid silicone rubbe...

Embodiment 2

[0023] (1) Using tetraethyl orthosilicate (TEOS) as the precursor and absolute ethanol as the flux, after mixing according to the mass ratio of tetraethyl orthosilicate: absolute ethanol: ammonia water = 1:20:1, at a temperature of 65°C Stir down, prepare silica sol;

[0024] (2) The silica sol was modified, and 10 wt% of epoxy silane coupling agent Coatosil 1770GE was added, and stirred at room temperature. Then carry out vacuum defoaming treatment;

[0025] (3) Clean the surface of the porcelain insulator, dip it in a methanol solution containing 3wt% N-β-aminoethyl-γ-aminopropylmethyldimethoxysilane for 10 minutes, take it out and dry it naturally;

[0026] (4) Put the porcelain insulator in the modified silica sol for pull-coating, form a coating on the surface of the porcelain insulator, dry it naturally and put it in an oven for heat treatment at 100 degrees Celsius;

[0027] (5) Add curing agent DACH (1,2, diaminocyclohexane) to the addition-type RTV liquid silicone r...

Embodiment 3

[0030] (1) Using tetraethyl orthosilicate (TEOS) as the precursor and absolute ethanol as the flux, after mixing according to the mass ratio of tetraethyl orthosilicate: absolute ethanol: ammonia water = 1:20:1, at a temperature of 30°C Stir down, prepare silica sol;

[0031] (2) The silica sol was modified by adding 5 wt% of N-β-aminoethyl-γ-aminopropyltrimethoxysilane and stirring at room temperature. Then carry out vacuum defoaming treatment;

[0032] (3) Clean the surface of the porcelain insulator, dip it in a methanol solution containing 3wt% N-β-aminoethyl-γ-aminopropylmethyldimethoxysilane for 5 minutes, take it out and dry it naturally;

[0033] (4) Put the porcelain insulator in the modified silica sol for pulling coating, form a coating on the surface of the porcelain insulator, dry it naturally and put it in an oven for heat treatment at 120 degrees Celsius;

[0034] (5) Add curing agent DACH (1,2, diaminocyclohexane) to the addition-type RTV liquid silicone rubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com