Method for preparing superhydrophobic coating by nano-crystalline cellulose template method

A nano-cellulose and super-hydrophobic coating technology, applied in the direction of cellulose coatings, coatings, etc., can solve the problems of poor water resistance and mechanical properties, achieve low surface energy, enhance hydrophobic properties, and guarantee the wear resistance of the coating film Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

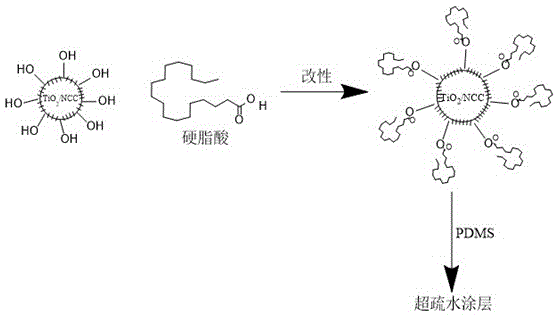

[0029] A method for preparing a superhydrophobic coating with a nanocellulose template method, comprising the steps of:

[0030] One, take microcrystalline cellulose as raw material sulfuric acid hydrolysis method to prepare nanocellulose solution, specific material dosage ratio is MCC:H 2 SO 4 =1: 8.45g / ml, react in a constant temperature water bath at 40°C for 95min. Add volume ratio to H 2 SO 4 :H 2 O=1:2.5 deionized water terminates the acid hydrolysis reaction. The sample was centrifuged at 6000r / m for 5min, the supernatant was poured off, the centrifugation was repeated 3 times, and ultrasonic treatment was performed at 70% power for 20min. Get nanocellulose solution (NCC); 2. Press V (TiCl 4 ):V(NCC)=1:10 will TiCl 4 Slowly drop into the nanocellulose solution, and stir mechanically at 70°C for 4 hours; 3. Add stearic acid dissolved in ethanol (according to adding TiCl 4 8% by mass), distilled water: absolute ethanol: stearic acid = 50: 4.5: 0.8, stirred at 70°C...

Embodiment 2

[0033] A method for preparing a superhydrophobic coating with a nanocellulose template method, comprising the steps of:

[0034] One, take microcrystalline cellulose as raw material sulfuric acid hydrolysis method to prepare nanocellulose solution, specific material dosage ratio is MCC:H2 SO 4 =1: 8.74g / ml, react in a constant temperature water bath at 40°C for 100min. Add volume ratio to H 2 SO 4 :H 2 O=1:2.8 deionized water terminates the acid hydrolysis reaction. The sample was centrifuged at 6000r / m for 5min, the supernatant was poured off, the centrifugation was repeated 3 times, and ultrasonic treatment was performed at 70% power for 25min. Get nanocellulose solution (NCC); 2. Press V (TiCl 4 ):V(NCC)=1:10 will TiCl 4 Slowly drop into the nanocellulose solution, and stir mechanically at 70°C for 4 hours; 3. Add stearic acid dissolved in ethanol (according to adding TiCl 4 Mass 8.2%), distilled water: absolute ethanol: stearic acid=50:6:1.5, stirred at 70°C for 2h,...

Embodiment 3

[0037] A method for preparing a superhydrophobic coating with a nanocellulose template method, comprising the steps of:

[0038] One, take microcrystalline cellulose as raw material sulfuric acid hydrolysis method to prepare nanocellulose solution, specific material dosage ratio is MCC:H 2 SO 4 =1: 9.3g / ml, react in a constant temperature water bath at 40°C for 98min. Add volume ratio to H 2 SO 4 :H 2 O=1:3.2 deionized water terminates the acid hydrolysis reaction. The sample was centrifuged at 6000r / m for 5min, the supernatant was poured off, the centrifugation was repeated 4 times, and ultrasonic treatment was performed at 70% power for 28min. Get nanocellulose solution (NCC); 2. Press V (TiCl 4 ):V(NCC)=1:10 will TiCl 4 Slowly drop into the nanocellulose solution, and stir mechanically at 70°C for 4 hours; 3. Add stearic acid dissolved in ethanol (according to adding TiCl 4 8.2% by mass), distilled water: absolute ethanol: stearic acid = 50: 6.5: 0.7, stirred at 70°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com