Preparation method of self-cleaning antireflection film with photocatalytic function on surface

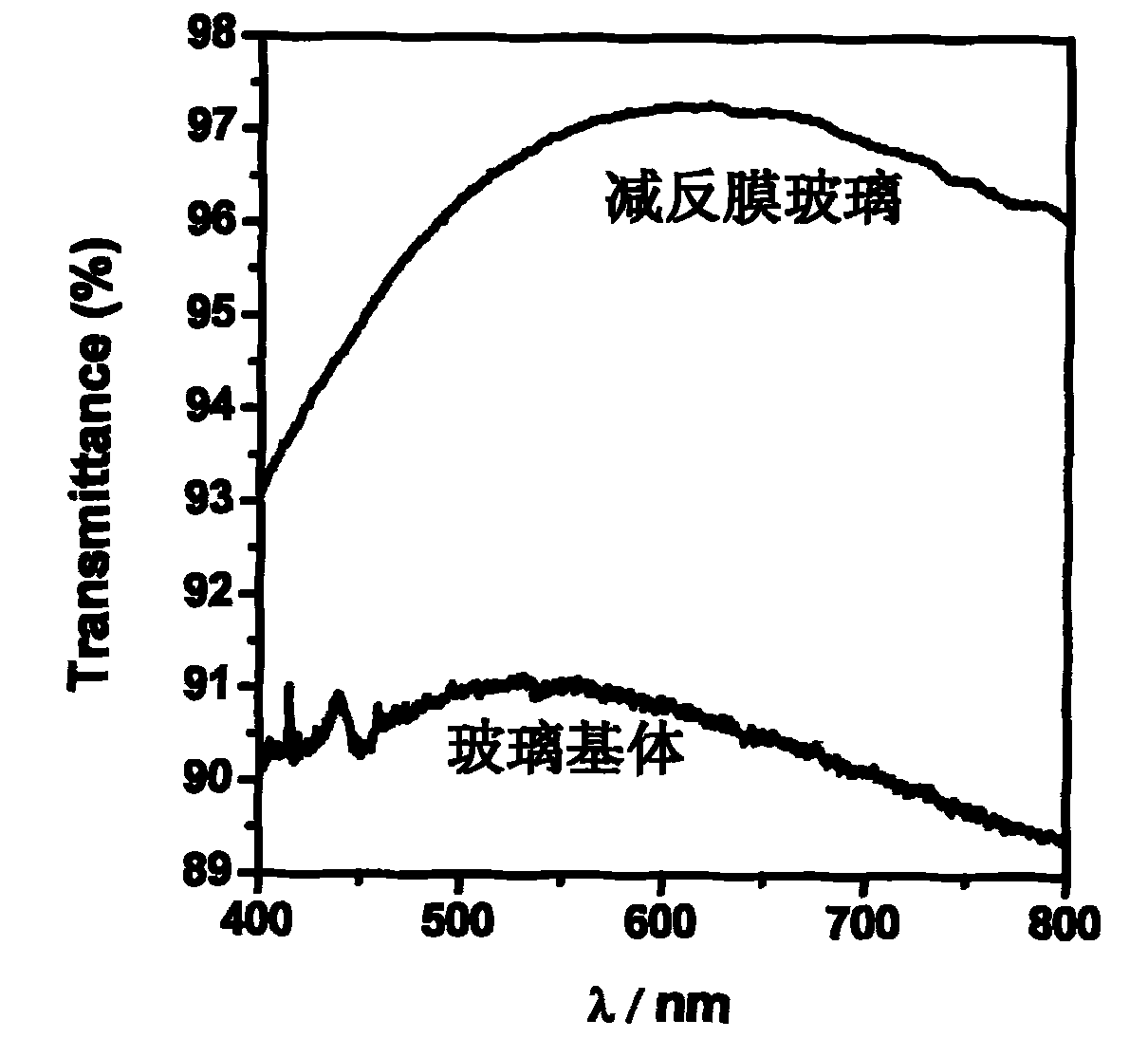

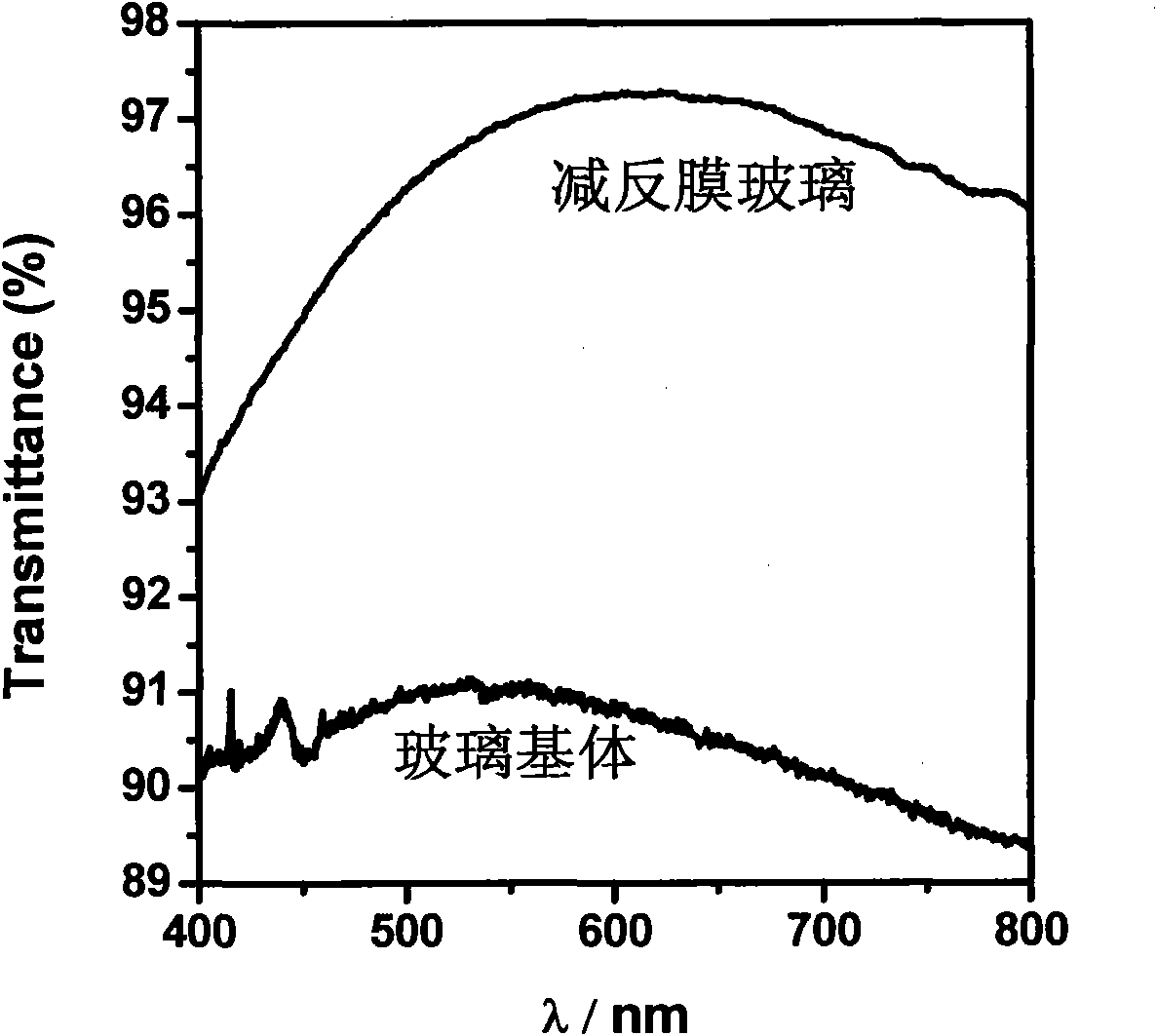

A technology of anti-reflection film and photocatalysis, which is applied in the field of solar photocatalysis, can solve the problems of high refractive index of titanium oxide film, reduce the light transmittance of anti-reflection film, etc., and achieve the effect of high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1: Add 53mL of absolute ethanol, 3.2mL of deionized water and about 0.04mL of concentrated hydrochloric acid (mass fraction is 37%) in a clean beaker successively, and under magnetic stirring conditions, add 10mL of ethyl orthosilicate dropwise, wherein ethanol : tetraethyl orthosilicate: water: the molar ratio of hydrochloric acid is 20: 1.0: 4.0: 0.01, sealed and stirred for 5 hours, and aged at room temperature for 3 days to obtain Sol I. Add 95mL of absolute ethanol and 2.5mL of concentrated ammonia water (mass fraction 28%) in a clean beaker, stir magnetically, and add 10mL of TEOS solution dropwise, wherein the molar ratio of ethyl silicate: water: ethanol: ammonia water is 1:2 : 37: 0.8, magnetically stirred for 6 hours, aged at room temperature for 5 days, and refluxed at 78°C for 8 hours to obtain Sol II. Sol II and Sol I were mixed at a volume ratio of 4:1, and after stirring for 1 hour, an acid-base mixed silica sol was obtained, which was designated ...

Embodiment 2

[0017] Example 2: Mix Sol II and Sol I in Example 1 at a volume ratio of 3:1, and stir for 1 hour to obtain an acid-base mixed silica sol, which is designated as Sol V. Add 64.5mL absolute ethanol, 1.05mL deionized water and 2.85mL hydrochloric acid successively in a clean beaker, place the beaker on a magnetic stirrer and add 15ml of butyl phthalate solution dropwise while stirring, wherein ethanol: butyl phthalate : water: the molar ratio of hydrochloric acid is 25: 1.0: 4.0: 0.75; the sol prepared above is placed on a magnetic stirrer and stirred for about 4 hours in a sealed manner, and aged for 1 day. Then dilute the above titanium sol with absolute ethanol, the molar ratio of ethanol and butyl phthalate after dilution is 150:1 to obtain the titanium sol, denoted as sol VI.

[0018] Put 2×10cm glass substrates (light transmittance 90%) into 10% hydrochloric acid and 10% NaOH solution for 2 hours in sequence, then fully wash with absolute ethanol and distilled water by ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com