A nanometer or nanometer porous carbon fiber bundle, a preparing method thereof and applications of the bundle

A nanoporous carbon and fiber bundle technology, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, hybrid capacitor electrodes, etc., can solve the problems that the diameter of the drawn fiber cannot be easily controlled, it is difficult to prepare carbon fiber bundles on a large scale, and the conditions are harsh, etc., to achieve Good electrochemical performance, controllable microstructure, and controllable diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

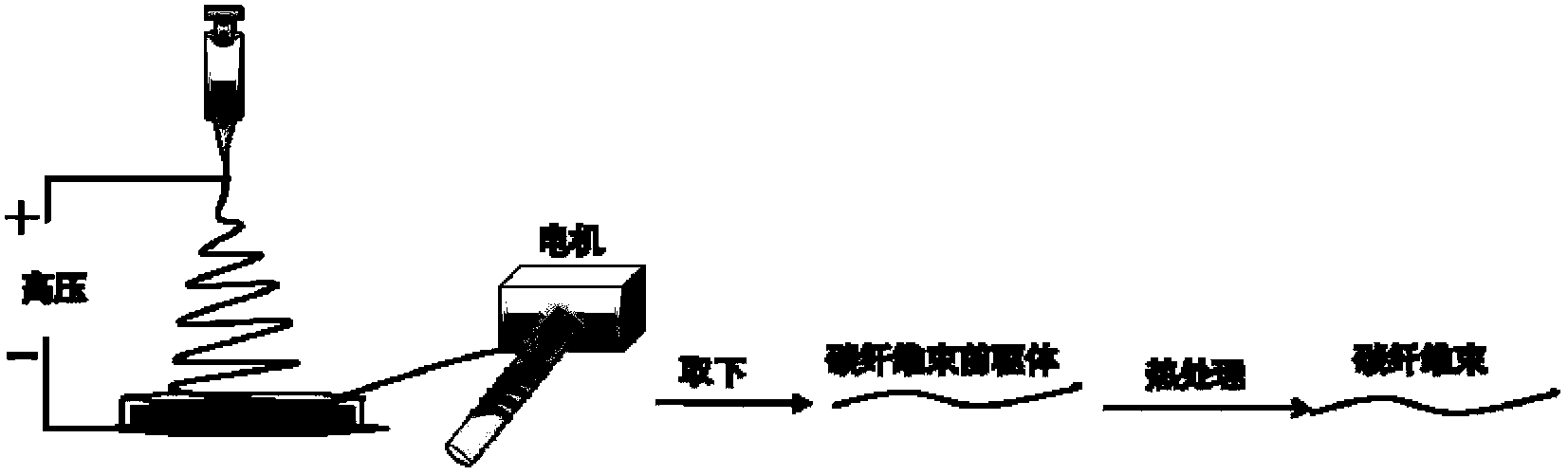

[0023] The present invention provides a method for preparing nanometer or nanoporous carbon fiber bundles, wherein the method comprises the following steps: (1) Suspending the precursors prepared by electrospinning a solution or melt containing spinnable polymers in the liquid phase In the receiving screen; (2) extracting the raw silk in the liquid-phase receiving screen at a speed of 5-60 rpm and winding the raw silk onto the silk take-off shaft to obtain a continuous directional array of raw silk bundles; ( 3) Heating and carbonizing the raw filament bundles in sections.

[0024] According to the present invention, the spinnable polymer can be any polymer that can be suspended in the liquid-phase receiving screen by nano wire bundles through electrospinning technology, preferably, it can be polyacrylonitrile, polymethacrylate, One or more of polyvinylpyrrolidone, polyvinyl alcohol, polystyrene and polylactic acid, preferably one or more of polyacrylonitrile, polymethacrylate...

Embodiment 1

[0064]At 80°C, polyacrylonitrile was dissolved in N,N-dimethylformamide at a mass ratio of 1:9 to prepare a solution of polyacrylonitrile in N,N-dimethylformamide. Then carry out electrospinning, wherein the consumption of solution is 1mL, the diameter of the metal needle of the glass tube is 0.7mm, and the metal needle of the glass tube is inclined at 35.9 degrees with the horizontal line, the voltage of the high-voltage power supply is 15kV, and the liquid-phase receiving screen is Distilled water, the distance between the spinning nozzle and the liquid-phase receiving screen is 15 cm, and the extrusion rate of the nozzle is 1 ml / hour; after the raw silk prepared by electrospinning is suspended in the liquid-phase receiving screen to form a fiber film, the The raw silk in the liquid-phase receiving screen is extracted at a speed of 1 minute and the raw silk is wound on the take-off shaft to obtain a continuous directional arrangement of the raw silk; then, the raw silk is hea...

Embodiment 2

[0066] Carbon nanofiber bundles were prepared in the same manner as in Example 1, except that the raw filaments in the liquid-phase receiving screen were extracted at a speed of 10 rpm. As a result, continuous nanocarbon fiber bundles with an average diameter of 300 microns, an average length of 5 cm, and an average specific surface area of 10 square meters per gram were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com