Method for preparing ultra-flat copper monocrystalline film

A single crystal thin film and single crystal technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as difficulty in preparing large-sized thin films, limiting the application of copper thin films, and damage to copper single crystals, etc. High repeatability, smooth surface, diameter controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, preparation of 4 inch copper single crystal by magnetron sputtering

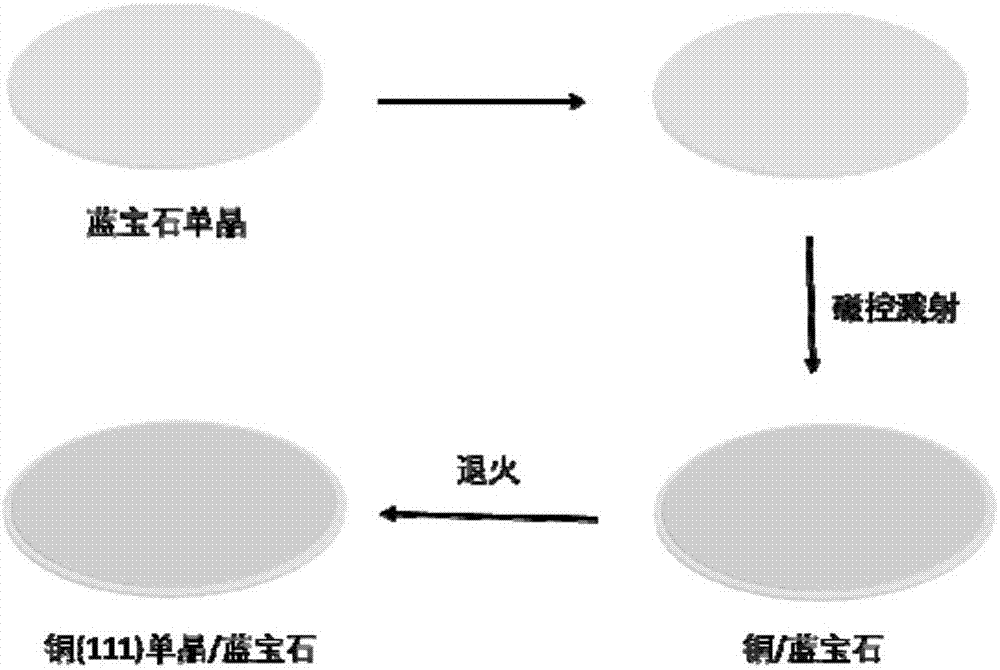

[0039] The overall process is as figure 1 shown.

[0040] Step (1): Use a sapphire single crystal purchased from Jiangyin Ruibo Electronic New Material Co., Ltd.; the sapphire single crystal is c-plane (0001); the thickness of the sapphire single crystal is not limited, usually 0.65mm, and the size is 4 inches. its photo as figure 2 shown.

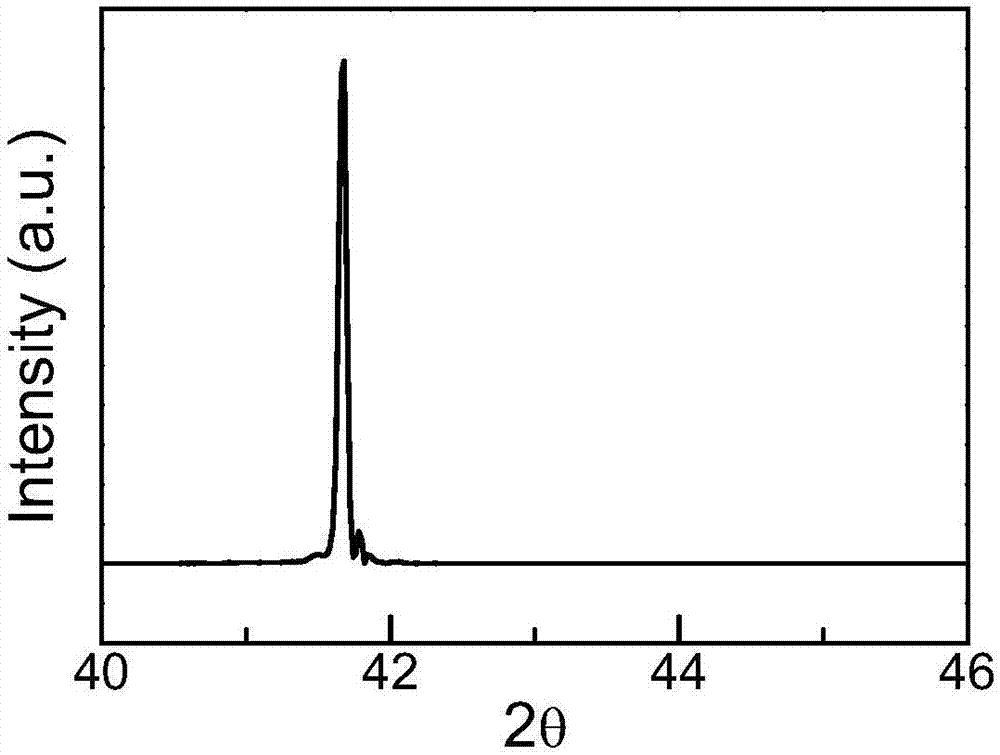

[0041] Step (2): Cleaning to improve the surface state of the sapphire and remove defects, fractures or impurities generated during the cutting process. The cleaning conditions are: phosphoric acid: sulfuric acid = 3.1 (v / v), temperature: 300°C, cleaning time: 1h ; then rinse several times in deionized water, and finally blow dry with a nitrogen gun. The X-ray diffraction pattern of the cleaned sapphire is as follows image 3 As shown, it can be seen that only Al 2 o 3 (0006) peak, indicating that the sapphire used is a single crystal.

[00...

Embodiment 2

[0045] Embodiment 2, preparation of twinned copper single crystal by magnetron sputtering

[0046] 1) step is with embodiment 1 step 1);

[0047] 2) step is the same as embodiment 1 step 2);

[0048] 3) Step: Do not anneal the sapphire single crystal

[0049] 4) step is the same as embodiment 1 step 4);

[0050] 5) step is the same as embodiment 1 step 5); adopt high-resolution X-ray diffraction characterization to the copper after stepping back, its in-plane scanning is as follows Figure 10 As shown in , it can be seen that there are 6 peaks in the plane of copper, which indicates that copper is a single crystal with twins. Electron microscopy was used to characterize the annealed copper, as shown in Figure 11 As shown, it can be seen that the copper surface becomes very flat after annealing, but there are twin grain boundaries. The annealed copper was characterized by atomic force microscopy, as shown in Figure 12 As shown, it can be seen that the copper surface bec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com