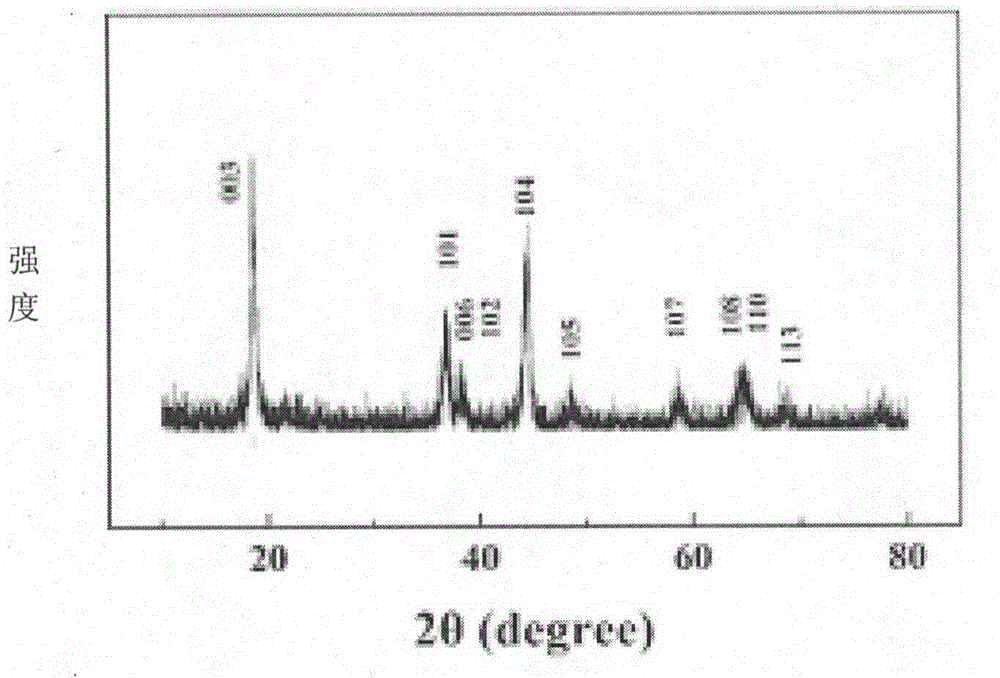

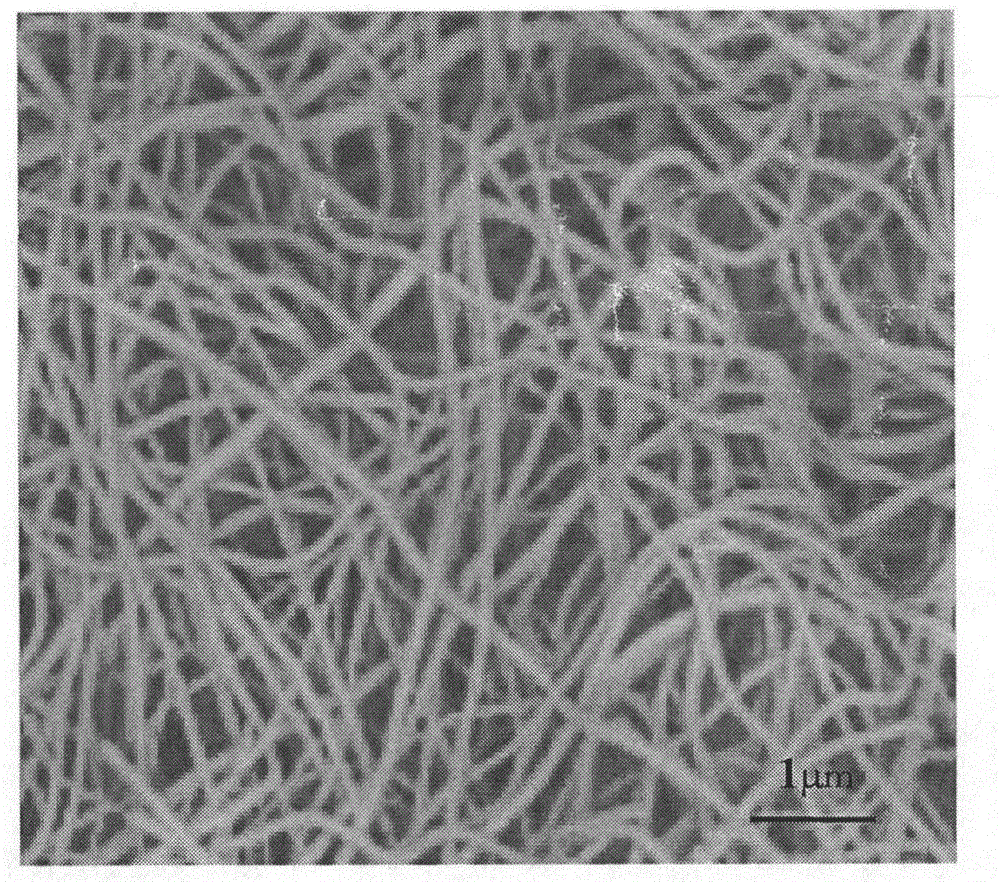

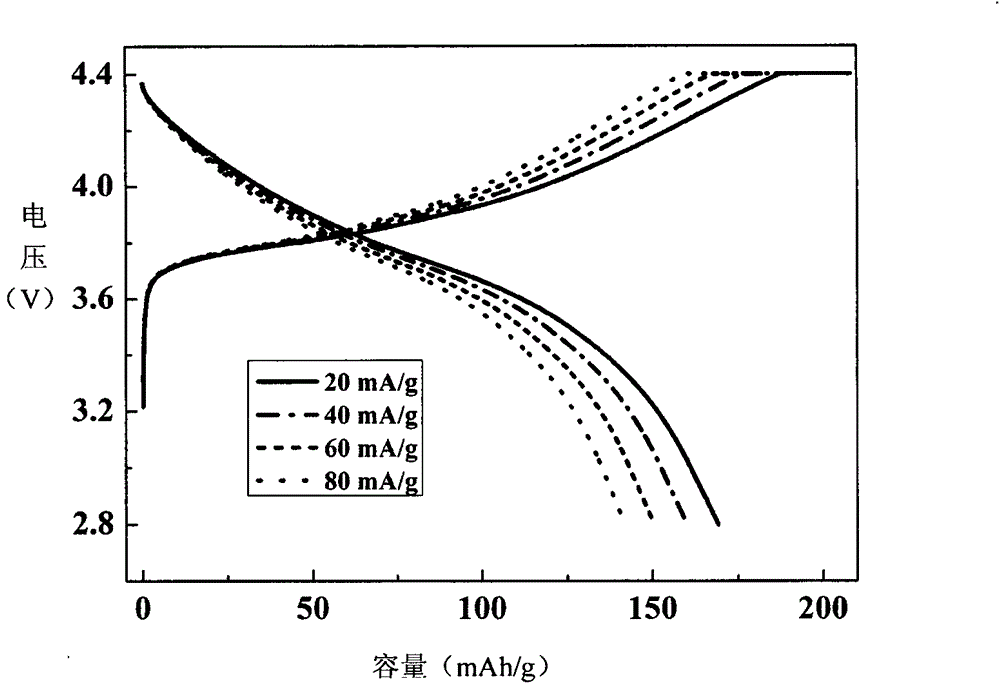

Preparation method for synthesizing LiNi1/3Co1/3Mn1/3O2 nanometer fiber by using electro-spinning technique

An electrospinning technology and nanofiber technology are applied in the field of lithium ion battery electrode materials and their preparation, which can solve the problems of lack of lithium ion positive electrode materials, difficulty in lithium ion deintercalation, poor crystal stability, etc., so as to improve electrochemical performance, Simple preparation method and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Synthesis of LiNi by an electrospinning technique 1 / 3 co 1 / 3 mn 1 / 3 o 2 The preparation method of nanofiber, the method step is as follows,

[0022] Lithium nitrate, nickel nitrate, cobalt nitrate and manganese acetate are dissolved in deionized water in a molar ratio of 3:1:1:1, and then complexing agent polyacrylic acid (relative molecular mass is 1000, solid content is 30%), It is configured so that the total concentration of cations (Li+Ni+Co+Mn) is a mixed solution of 0.6mol / L, and the amount of polyacrylic acid added is based on polyacrylic acid and metal cations (Li + +Ni 2+ +Co 2+ +Mn 2+ ) is measured by the molar ratio R of the total amount of substances, and R is 0.75. The mixed solution is heated and stirred in a water bath at 60° C. for 2 h to obtain a transparent red solution. Then add polyvinylpyrrolidone (PVPK90) that is ground (grinding 10min before polyvinylpyrrolidone is used), and its content is 5% (percentage by weight) of the sum of the conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com