Polypyrrole-sensitized hollow titanium dioxide nanometer photocatalyst and preparation method thereof

A nano-photocatalyst, titanium dioxide technology, applied in the field of preparation of new photocatalytic materials, can solve the problems that have not yet been seen and limit the application of industrialization, and achieve the effects of low cost, simple preparation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

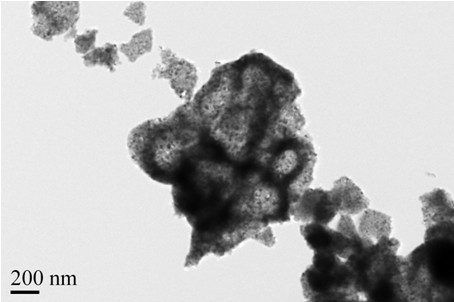

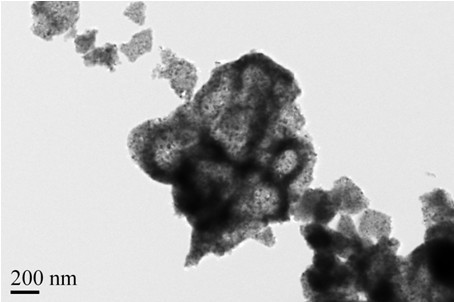

Image

Examples

Embodiment 2

[0025] 1) Prepare carbon spheres by hydrothermal synthesis of 0.15 g / ml glucose solution at a hydrothermal temperature of 180 °C for 8 h;

[0026] 2) Hydrolyze butyl titanate into titanium dioxide sol by sol-gel method, and load it on the surface of carbon spheres prepared in step 1) by stirring, the mass ratio of butyl titanate to carbon spheres is 10:1, Preparation of C / titania microspheres;

[0027] 3) Calcining the C / titanium dioxide microspheres prepared in step 2) at 350 °C for 2 h to obtain hollow titanium dioxide microspheres;

[0028] 4) Pyrrole was oxidized into polypyrrole by chemical in-situ polymerization in a solution with a hydrochloric acid concentration of 1 mol / l, and it was loaded onto the surface of hollow titanium dioxide microspheres prepared in step 3) by stirring. In the synthesis system, pyrrole and hollow The molar ratio of titanium dioxide microspheres is 1:100, and finally a polypyrrole-sensitized hollow titanium dioxide nanometer photocatalyst is ...

Embodiment 3

[0031] 1) Prepare carbon spheres by hydrothermal synthesis of 0.5 g / ml glucose solution at a hydrothermal temperature of 180 °C for 8 h;

[0032] 2) Hydrolyze butyl titanate into titanium dioxide sol by sol-gel method, and load it on the surface of carbon spheres prepared in step 1) by stirring, the mass ratio of butyl titanate to carbon spheres is 10:1, prepare C / titanium dioxide microspheres;

[0033] 3) Calcining the C / titanium dioxide microspheres prepared in step 2) at 450°C for 2 h to obtain hollow titanium dioxide microspheres;

[0034] 4) Pyrrole was oxidized into polypyrrole by chemical in-situ polymerization in a solution with a hydrochloric acid concentration of 1.5 mol / l, and it was loaded onto the surface of hollow titanium dioxide microspheres prepared in step 3) by stirring. In the synthesis system, pyrrole and hollow The molar ratio of titanium dioxide microspheres is 1:100, and finally a polypyrrole-sensitized hollow titanium dioxide nanometer photocatalyst ...

Embodiment 4

[0037] 1) Prepare carbon spheres by hydrothermal synthesis of 0.15 g / ml glucose solution at a hydrothermal temperature of 150 °C for 8 h;

[0038] 2) Hydrolyze butyl titanate into titanium dioxide sol by sol-gel method, and load it on the surface of carbon spheres prepared in step 1) by stirring, the mass ratio of butyl titanate to carbon spheres is 10:1, prepare C / titanium dioxide microspheres;

[0039] 3) Calcining the C / titanium dioxide microspheres prepared in step 2) at 450 °C for 2 h to obtain hollow titanium dioxide microspheres;

[0040] 4) Pyrrole was oxidized into polypyrrole by chemical in-situ polymerization in a solution with a hydrochloric acid concentration of 0.5 mol / l, and it was loaded onto the surface of hollow titanium dioxide microspheres prepared in step 3) by stirring. In the synthesis system, pyrrole and hollow The molar ratio of titanium dioxide microspheres is 1:100, and finally a polypyrrole-sensitized hollow titanium dioxide nanometer photocatalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com