Method for green synthesis of fluorescent chiral carbon dots

A green synthesis, chiral carbon technology, applied in the fields of nanomaterials science and biomedical engineering, can solve the problems of complex preparation scheme, difficult separation and purification, etc., and achieve the effects of controllable particle diameter, simple synthesis method and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

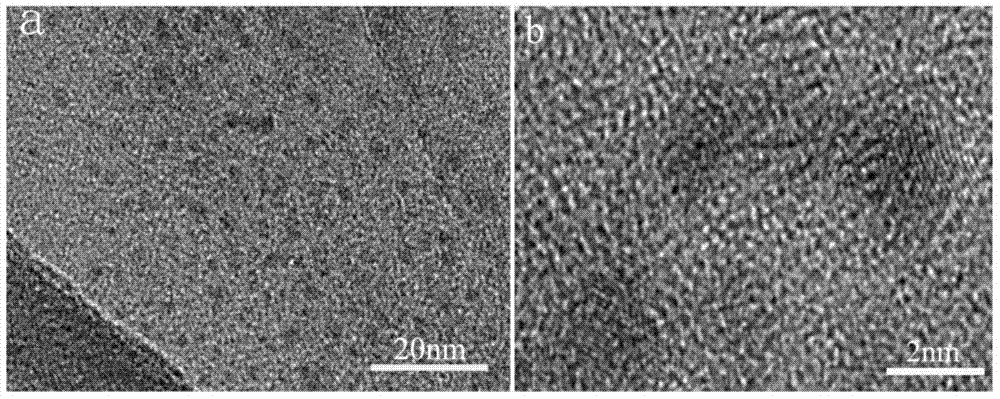

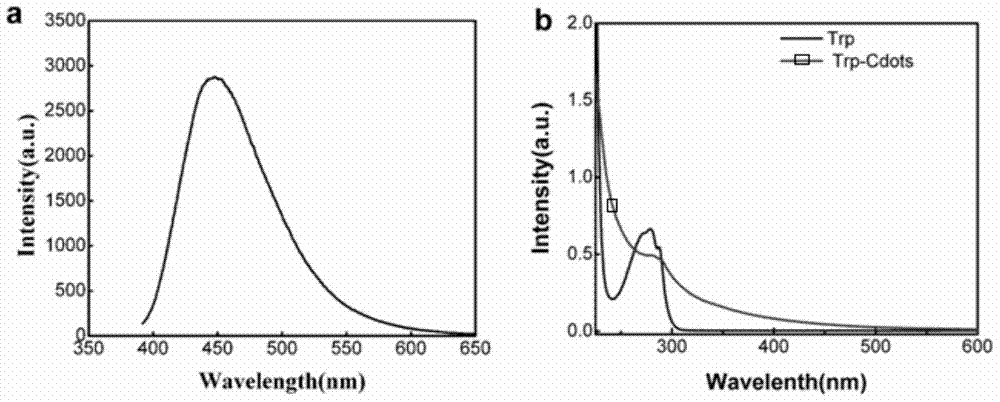

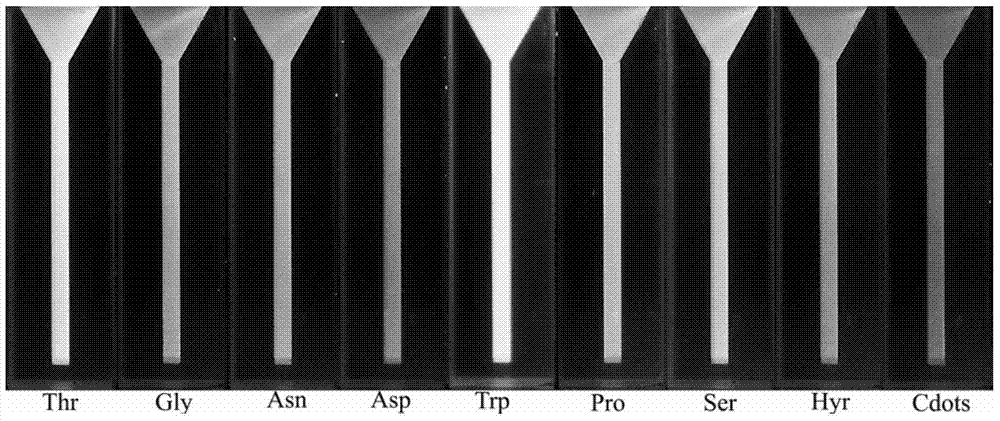

[0029] Example 1, using citric acid as a precursor and L-tryptophan (L-Trp) as an auxiliary reagent to prepare fluorescent carbon dots.

[0030] Step 1: At room temperature, weigh 1g of citric acid, 10mg of L-tryptophan, and 5mL of H 2 O was added to a 25mL glass reaction bottle, and ultrasonic treatment was performed at a working frequency of 40kHz and an ultrasonic power of 200W for 1min to obtain a transparent aqueous solution.

[0031]Step 2: Put the mixed solution obtained in Step 1 into a microwave oven for 4 minutes at a power of 800W, and obtain a brownish-yellow liquid after reaction.

[0032] Step 3: Dialyze the product obtained in Step 2 with a dialysis bag with a molecular weight cut-off of 1000 for 36 hours. During the dialysis process, the ultrapure water should be replaced continuously to remove unreacted citric acid and tryptophan to obtain the fluorescence of the surface amino acid The carbon quantum dots have a fluorescence quantum yield of 19.27%.

Embodiment 2

[0033] Example 2, using glucose as a precursor and d-tryptophan (D-Trp) as a biosynthetic template to prepare fluorescent carbon dots.

[0034] Step 1: At room temperature, weigh 1 g of glucose, 5 mg of D-tryptophan, and 5 mL of H 2 O was added to a 25mL glass reaction bottle, and the working frequency was 40kHz, and the ultrasonic power was 200W, and the ultrasonic treatment was performed for 1min to obtain a uniform aqueous solution.

[0035] Step 2: Put the mixed solution obtained in Step 1 into a microwave oven for 4 minutes at a power of 800W, and obtain a brownish-yellow liquid after reaction.

[0036] Step 3: Dialyze the product obtained in Step 2 with a dialysis bag with a molecular weight cut-off of 1000 for 36 hours. During the dialysis process, the ultrapure water should be replaced continuously to remove unreacted glucose and tryptophan to obtain surface tryptophan-modified fluorescence Carbon dots have a fluorescence quantum yield of 9.57%.

Embodiment 3

[0037] Example 3, using glucose as a precursor and L-cysteine and D-cysteine as auxiliary synthesis reagents to prepare chiral fluorescent carbon dots.

[0038] Step 1: At room temperature, weigh 1g of glucose, 5mg of L-cysteine and R-cysteine, and put them into 5mL H 2 In a 25mL glass reaction vial of O, the ultrasonic treatment was performed for 1min at a working frequency of 40kHz and an ultrasonic power of 200W to obtain a uniform aqueous solution.

[0039] Step 2: The mixed solutions obtained in Step 1 were respectively placed in a microwave oven for 4 min at a power of 800 W, and a brownish-yellow liquid was obtained after the reaction.

[0040] Step 3: Put the products obtained in step 2 into dialysis bags with a molecular weight cut-off of 1000 for dialysis for 36 hours respectively. During the dialysis process, the ultrapure water should be replaced continuously to remove unreacted glucose and cysteine, and obtain different molecular weights. The fluorescent ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com