Polyimide nano-fiber and preparation method thereof

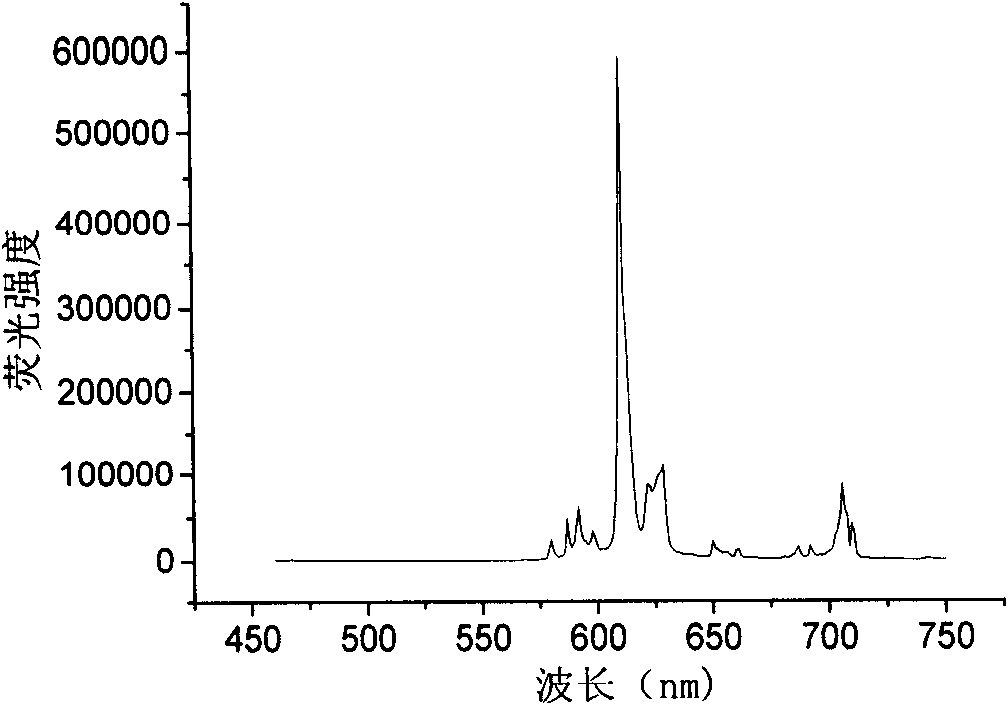

A nanofiber and polyimide technology, applied in fiber treatment, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problems of polyimide without fluorescence effect and coarse particle size, and achieve excellent fluorescence effect and Heat-resistant stability, low decomposition temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

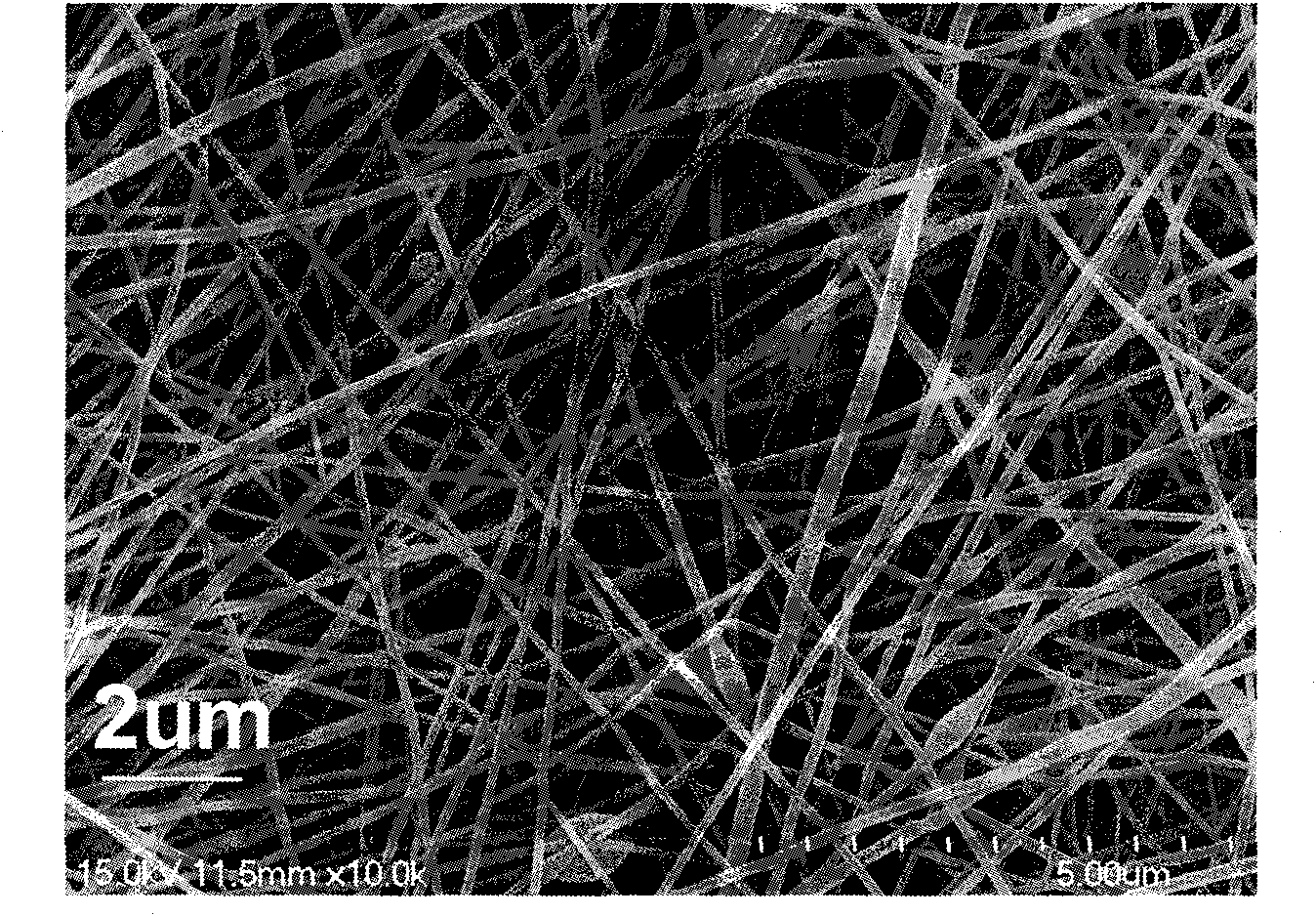

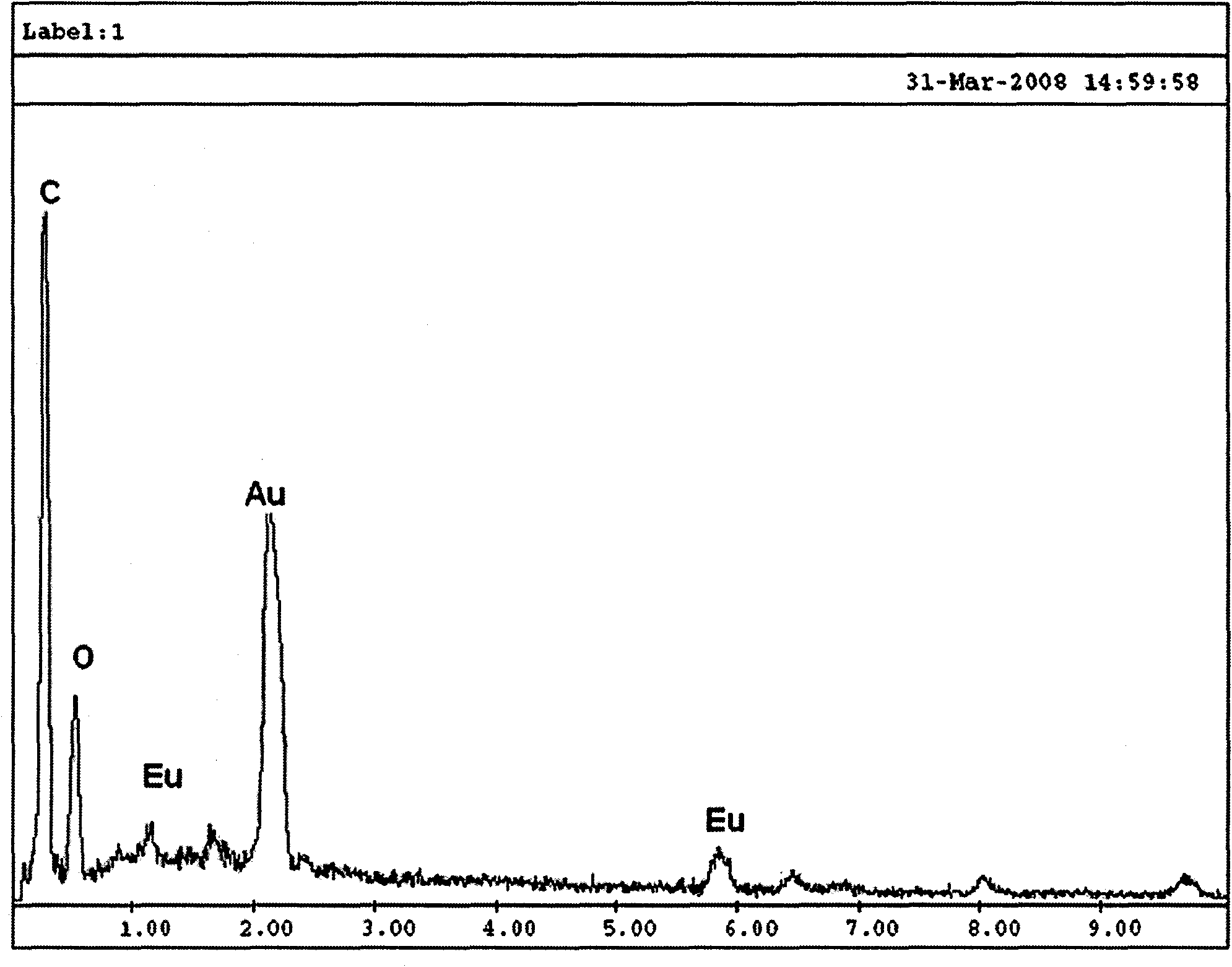

[0021] By weight, dissolve 1 part of 4,4'-diaminodiphenyl ether (ODA) in 4 parts of N,N-dimethylacetamide (DMAC) solvent, stir until ODA is completely dissolved in DMAC, and react Temperature at room temperature (about 0-10°C), add 1.025 parts of pyromellitic anhydride (PDMA) in four times, with an interval of half an hour between each addition. After the PDMA was added completely, a polyamic acid solution was obtained; 3 wt% of europium oxide based on the weight of the polyamic acid solution was added to continue the reaction. When the viscosity of the reaction system increases suddenly, it indicates that the system reaches the equivalence point, and the reaction is continued for 2 hours until the viscosity of the system is stable, and a PAA / europium oxide solution is obtained.

[0022] The above solution was injected into the spinning solution container of the electrospinning machine, the spinning temperature was room temperature, the output voltage of the high voltage power...

Embodiment 2

[0027] Add the europium oxide particles into the coupling agent solution, wherein the ratio of the europium-containing oxide particles to the coupling agent is 1:5g / ml, react under magnetic stirring, and dry naturally until the solvent evaporates after the reaction is completed. drying in an oven to obtain coupled surface-modified europium-containing oxide particles; the coupling agent is one or a combination of organic silane coupling agents and titanate coupling agents.

[0028] By weight, 1 part of 4,4'-diaminodiphenyl ether (ODA) was dissolved in 43 parts of N,N-dimethylacetamide (DMAC) solvent, stirred until ODA was completely dissolved in DMAC; reaction Temperature at room temperature (about 0-10°C), add 1.025 parts of pyromellitic anhydride (PDMA) in four times, with an interval of half an hour between each addition. After the PDMA was added completely, 1 wt% europium oxide treated with a coupling agent was added to continue the reaction. When the viscosity of the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com