Aerogel fiber as well as preparation method and application thereof

An aerogel fiber, aerogel technology, applied in the field of aerogel, to achieve the effect of protecting integrity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

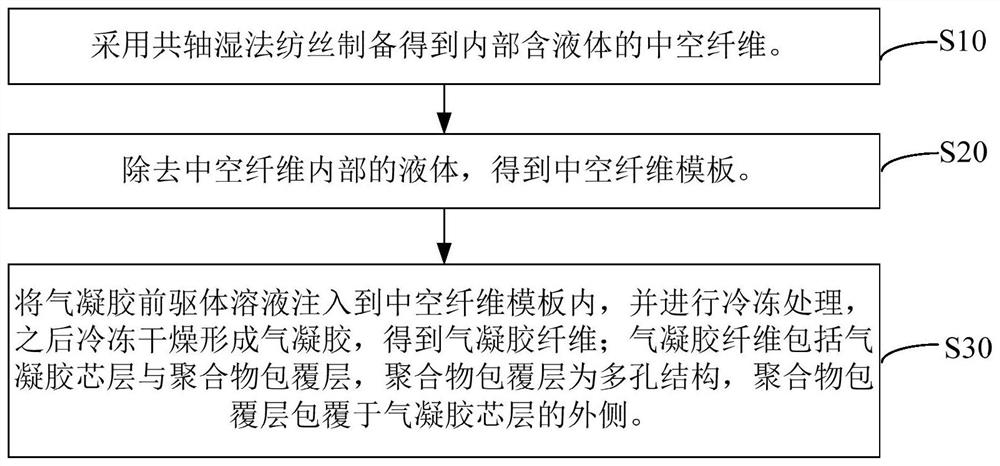

[0094] See figure 2 , the preparation method of the airgel fiber of one embodiment of the present invention, comprises the steps:

[0095] S10. Prepare a hollow fiber containing liquid inside by coaxial wet spinning.

[0096] Among them, the operation of preparing the hollow fiber containing liquid inside by coaxial wet spinning is:

[0097] The main spinning polymer is mixed with a solvent as the outer layer solution, and the liquid is used as the inner layer solution, and wet spinning is carried out in a liquid bath, and then impurities are removed to obtain a hollow fiber with a liquid inside.

[0098] Wherein, the impurities are solvents or other substances doped in the main spinning polymer.

[0099] S20, removing the liquid inside the hollow fiber to obtain a hollow fiber template.

[0100] Preferably, the operation of removing the liquid inside the hollow fiber is:

[0101] The hollow fibers are frozen and then freeze-dried; or air-dried at room temperature. Differ...

Embodiment 1

[0135] Preparation of cellulose fibers (CNFs): 1 g of rice straw (such as Figure 4 Shown) the cellulose in the alkaline solution of Ph=10.0 containing 0.016g TEMPO / 0.1gNaBr / 5mmol NaClO, by centrifugation and dialysis. The mixing speed is 37,00 rpm for 30 minutes; the centrifugation speed is 5,000 rpm for 15 minutes. The centrifuged supernatant was rotary evaporated to 0.7 wt% in a rotary evaporator, and stored at 4°C for future use.

[0136] Preparation of CA / PAA-coated airgel fibers:

[0137] In the wet spinning process, the hollow fiber first uses cellulose acetate (CA) as the main spinning polymer, and at the same time, polyacrylic acid (PAA) with a molecular weight of 4000kDa is added to CA, and dimethylacetamide (DMAc) is used as the solvent. , water fills the central channel.

[0138] Extrude 16wt% CA / PAA (23:2w / w) dissolved in DMAc into the water bath, the water inside and outside the hollow fiber can extract DMAc, and the phase change occurs simultaneously on the i...

Embodiment 2

[0152] Preparation of cellulose fibers (CNFs): 1 g of cellulose from rice straw was decomposed by centrifugation and dialyzed in an alkaline solution of Ph=10.0 containing 0.016 g TEMPO / 0.1 g NaBr / 5 mmol NaClO. The mixing speed is 37,00 rpm for 30 minutes; the centrifugation speed is 5,000 rpm for 15 minutes. The centrifuged supernatant was rotary evaporated to 0.7 wt% in a rotary evaporator, and stored at 4°C for future use.

[0153] Preparation of airgel precursor solution: 5.5 g of PEDOT / PSS solution (mass fraction 1.1 wt%) was added to 2.0 g of distilled water, and stirred at high speed for 30 min until uniformly dispersed, thereby preparing a mass fraction of 0.7% PEDOT / PSS dispersion. In order to obtain a PEDOT / PSS / CNF dispersion with a mass fraction of 0.7 wt%, add 5.5 g of PEDOT / PSS solution and CNF solution with equal mass fractions of 0.7 wt%, and stir at high speed for 30 minutes until the dispersion is uniform.

[0154] Preparation of TPE-coated conductive airgel fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com