Ultra-fine zinc oxide nonometer line and its preparation method

A zinc oxide nanowire, nanowire technology, applied in the direction of zinc oxide/zinc hydroxide, etc., achieves the effects of easy large-area synthesis, reduced production cost, simple and easy operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

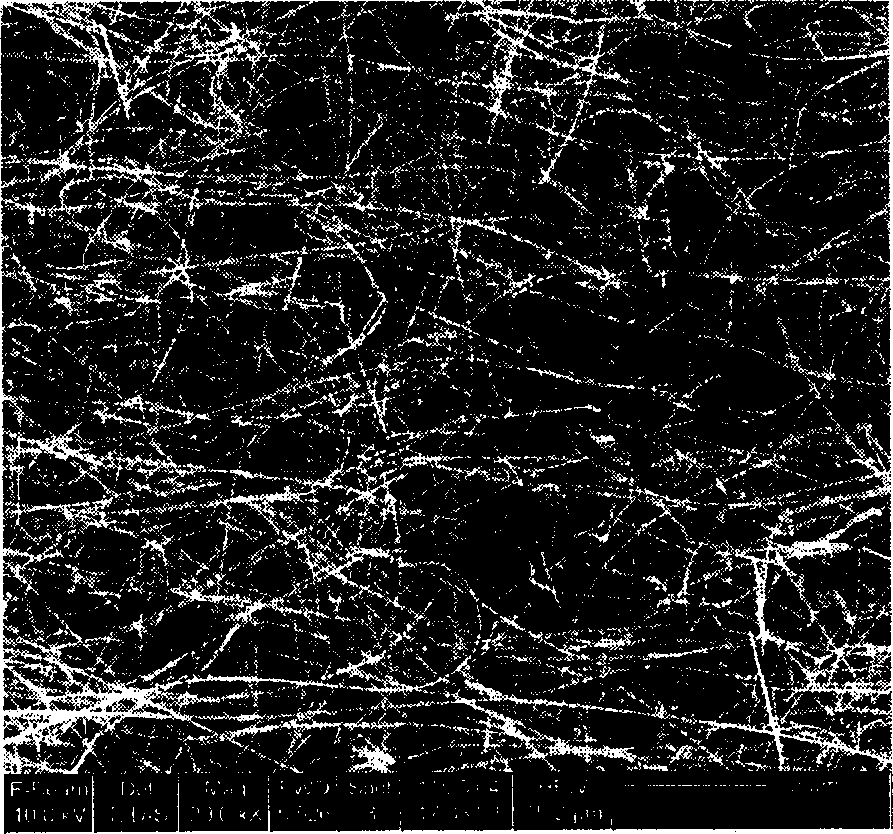

[0017] First, the n-type heavily doped silicon substrate coated with gold film was ultrasonically cleaned in acetone and alcohol for 10 minutes, and then rinsed with deionized water. The silicon wafer and the zinc evaporation source are placed on the glass wafer with a horizontal distance of 7 mm. Place the slide in the middle of the tube furnace with the evaporation source in the direction of the gas inlet. The system was evacuated and purged three times with argon. Then fill with 135 standard ml / min of high-purity Ar 2 As a protective atmosphere, the pressure in the reaction chamber is 0.03MPa. The temperature of the reaction chamber was raised to 500°C at a temperature increase rate of 20°C / min. Maintain high purity Ar at this time 2 flow rate, while introducing 1 standard ml / min of argon-oxygen mixed gas (O 2 / Ar: 5%), after 100 minutes of reaction, it was cooled to room temperature. The silicon wafer was removed and a layer of white product was deposited on it. The...

Embodiment 2

[0019] First, the n-type heavily doped silicon substrate coated with gold film was ultrasonically cleaned in acetone and alcohol for 10 minutes, and then rinsed with deionized water. The silicon wafer and the zinc evaporation source are placed on the glass wafer with a horizontal distance of 6 mm. Place the slide in the middle of the tube furnace with the evaporation source in the direction of the gas inlet. The system was evacuated and purged three times with argon. Then fill with 140 standard ml / min of high-purity Ar 2 As a protective atmosphere, the pressure in the reaction chamber is 0.05MPa. The temperature of the reaction chamber was raised to 460°C at a ramp rate of 15°C / min. Maintain high purity Ar at this time 2 flow rate, while introducing 2 standard milliliters / minute of argon-oxygen mixed gas (O 2 / Ar: 5 volume %), after 150 min of reaction, it was lowered to room temperature. The silicon wafer was removed and a layer of white product was deposited on it. Th...

Embodiment 3

[0021] First, the n-type heavily doped silicon substrate coated with gold film was ultrasonically cleaned in acetone and alcohol for 10 minutes, and then rinsed with deionized water. The silicon wafer and the zinc evaporation source are placed on the glass wafer with a horizontal distance of 8 mm. Place the slide in the middle of the tube furnace with the evaporation source in the direction of the gas inlet. The system was evacuated and purged three times with argon. Then fill with 150 standard ml / min of high-purity Ar 2 As a protective atmosphere, the pressure in the reaction chamber is 0.03MPa. The temperature of the reaction chamber was raised to 540°C at a temperature increase rate of 10°C / min. Maintain high purity Ar at this time 2 flow rate, while introducing 1 standard ml / min of argon-oxygen mixed gas (O 2 / Ar: 4%), after 100 minutes of reaction, it was cooled to room temperature. The silicon wafer was removed and a layer of white product was deposited on it. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com