Method for manufacturing silver nanowires

A technology of silver nanowires and silver salts, which is applied in the field of preparation of silver nanowires, can solve problems such as the inability to form silver nanowires in series, complex post-processing, and large sewage problems, and achieve large-scale production, convenient operation, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

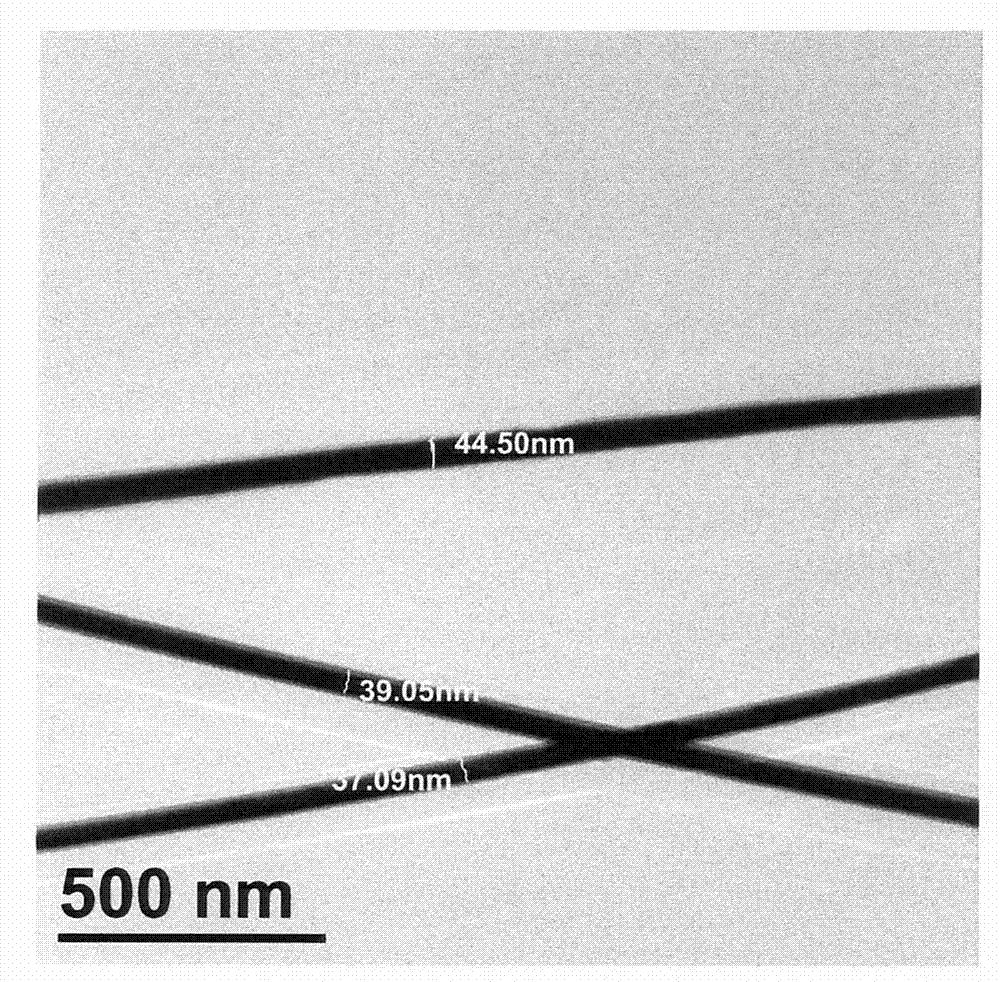

[0050] A method for preparing silver nanowires, comprising the steps of: (1) taking 1 gram of potassium chloride, 1 gram of polyvinylpyrrolidone, and adding 0.5 gram of glucose into 50 milliliters of water to stir or ultrasonically dissolve to obtain a mixed solution A; (2 ) Weigh 1 gram of gelatin and add it into 25 milliliters of water for ultrasonic vibration until it is completely dissolved; then take 0.75 grams of silver nitrate and add it to the above solution and fully stir and dissolve to obtain a mixed solution B; (3) mix the mixed solution A with the mixed solution B and stir evenly, then transfer to the reaction kettle, heat up to 140°C and keep it for 150 minutes, then stop heating to obtain the silver nanowire stock solution; (4) take water and ethanol in any ratio mixed solvent to dilute the silver nanowire stock solution by 5 times, and then use Centrifuge at 8000 rpm for 5 minutes and concentrate to obtain a silver nanowire concentrate; (5) place the silver nano...

Embodiment 2

[0053] On the basis of Example 1, only the consumption of silver nitrate in the step (2) is reduced to 0.5 gram in the preparation process, and other technological parameters remain unchanged, and the silver nitrate that the diameter is 40 nanometers, length is 30~40 microns is prepared. Nanowires.

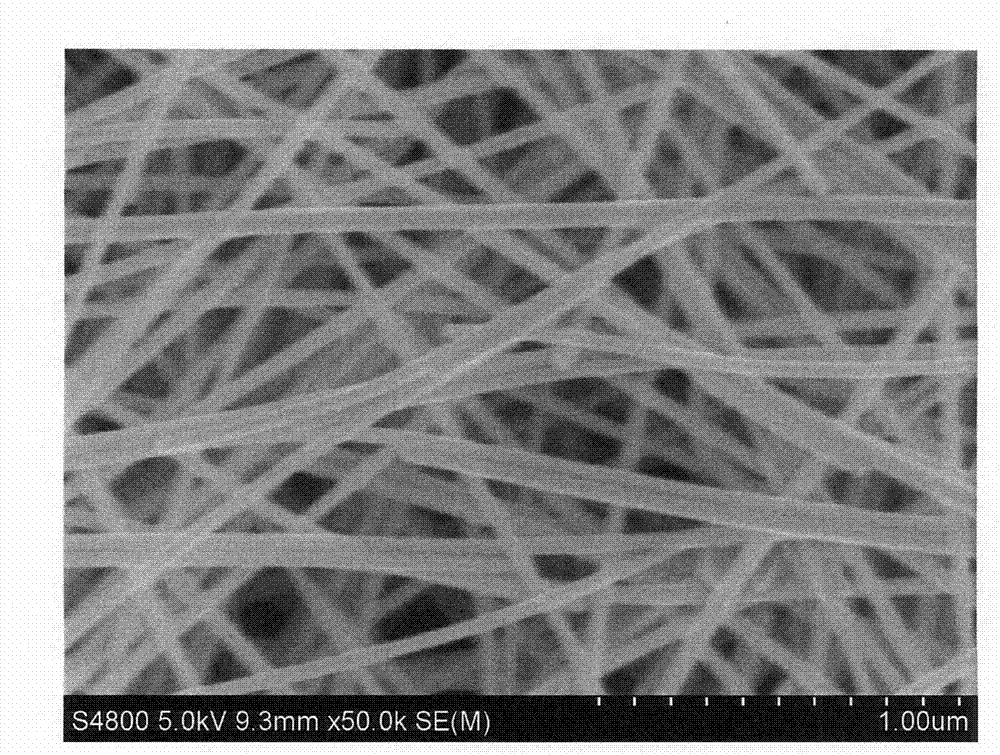

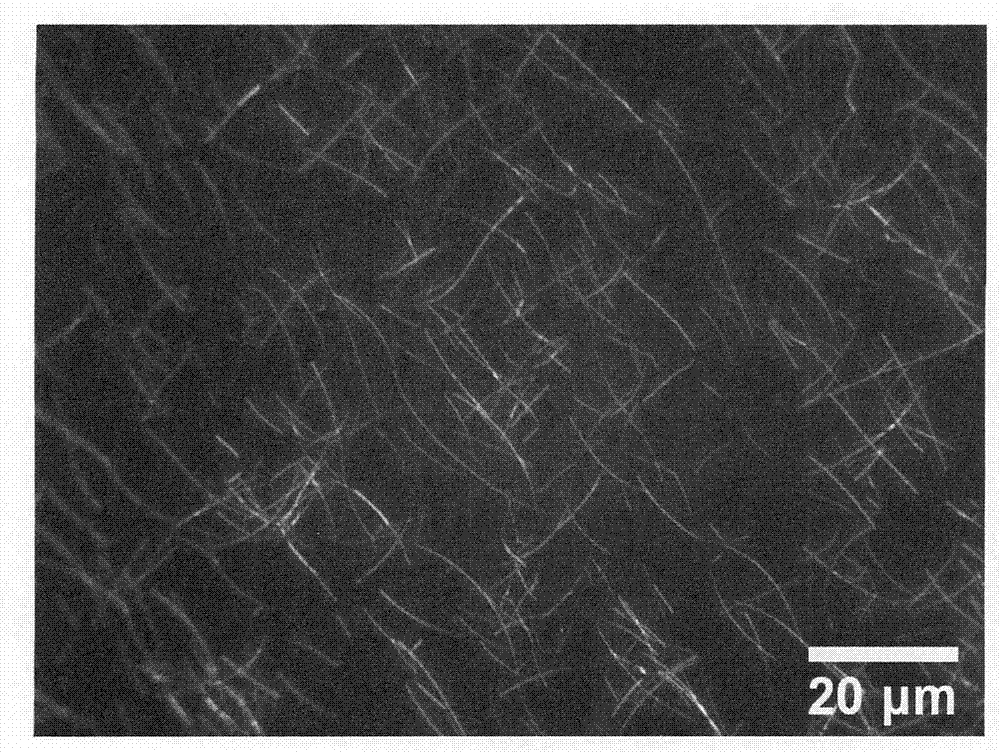

[0054] Figure 4 For the scanning electron micrograph of the silver nanowire powder product that this embodiment makes, by Figure 4 It can be seen that the silver nanowires are uniformly distributed. Figure 5 It is an optical microscope photo of the product. It can be seen from the figure that the obtained silver nanowires are evenly distributed, and the length is about 30-40 microns.

Embodiment 3

[0056] On the basis of Example 1, in the preparation process, the consumption of polyvinylpyrrolidone in step (1) is reduced to 0.75 grams, the consumption of silver nitrate in step (2) is reduced to 0.5 grams, and other process parameters remain unchanged. Silver nanowires with a diameter of 40 nanometers and a length of 1-5 micrometers are obtained.

[0057] Image 6 The scanning electron microscope picture of the silver nanowire powder product that is made in this embodiment, Figure 7 An optical microscope photograph of the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com