Zero discharge processing EBM method for dyeing waste water

A printing and dyeing wastewater and zero-discharge technology, which is applied in textile industry wastewater treatment, water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of high water consumption, high energy consumption, low turbidity, etc., and reduce product production cost, reduce the load of purification and reuse, and improve the effect of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention proposes a zero-discharge EBM method for printing and dyeing wastewater, such as figure 2 As shown, it is an integrated system of electric biochemical membrane technology, referred to as EBM (Electricity-Biochemistry-Membrane) system, which includes the following steps:

[0031] Step 1: Implement the centrifugal drying and countercurrent washing process in the dyeing and rinsing process;

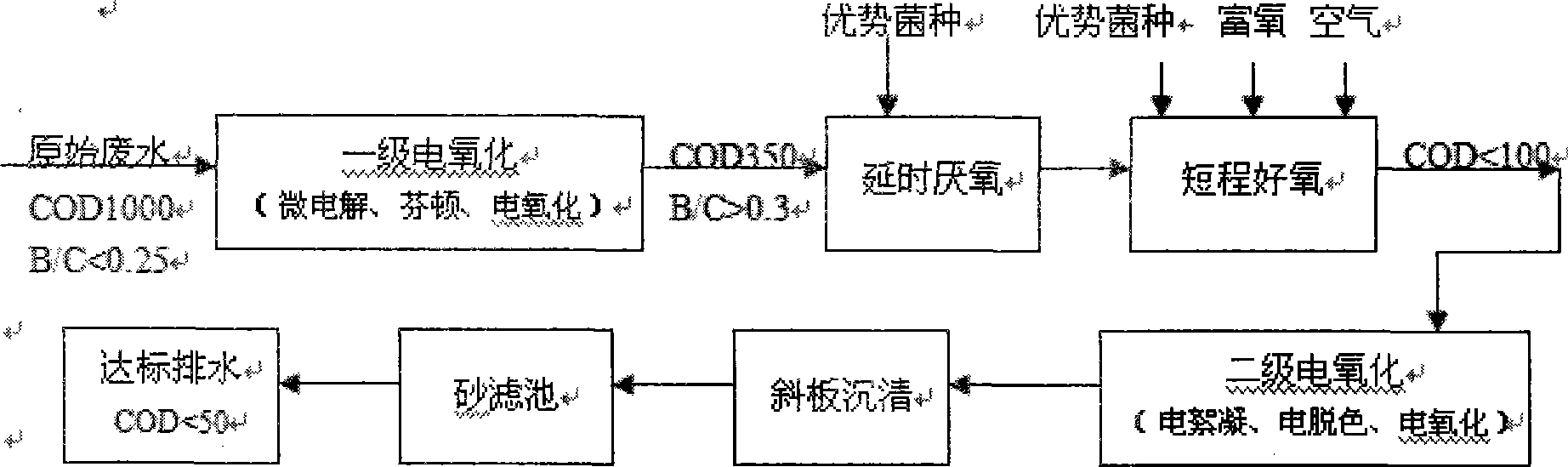

[0032] Step 2: If image 3 As shown, the printing and dyeing raw wastewater is treated up to the standard to obtain the standard discharge water;

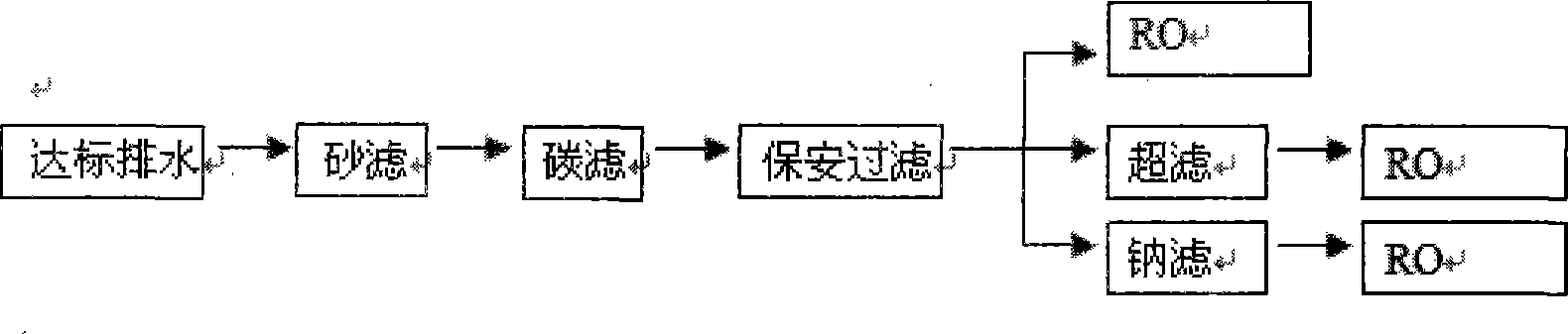

[0033] Step 3: If Figure 4 As shown, deep purification treatment is carried out on the discharge water up to the standard to obtain fresh water and high-concentration water, and the fresh water is reused;

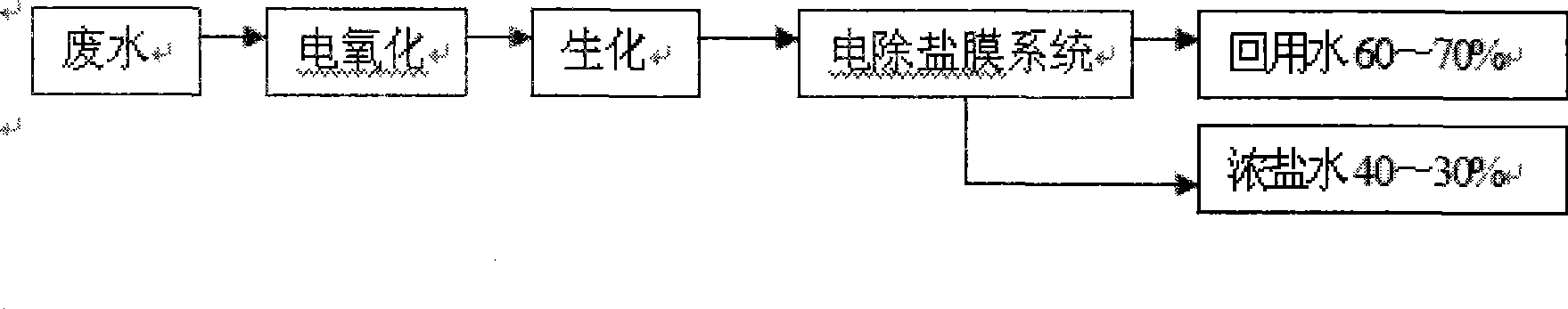

[0034] Step 4: If Figure 5 As shown, the high concentration water is treated.

[0035] Each step is described in detail below.

[0036] In step 1, the most commonly used and most mature centrifugal drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com