Method for treating industrial waste water by means of photoelectrocatalysis

A photoelectric catalysis, industrial wastewater technology, applied in chemical instruments and methods, light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of powder falling off, photocatalytic effect attenuation, etc. Visible light response, the process is environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

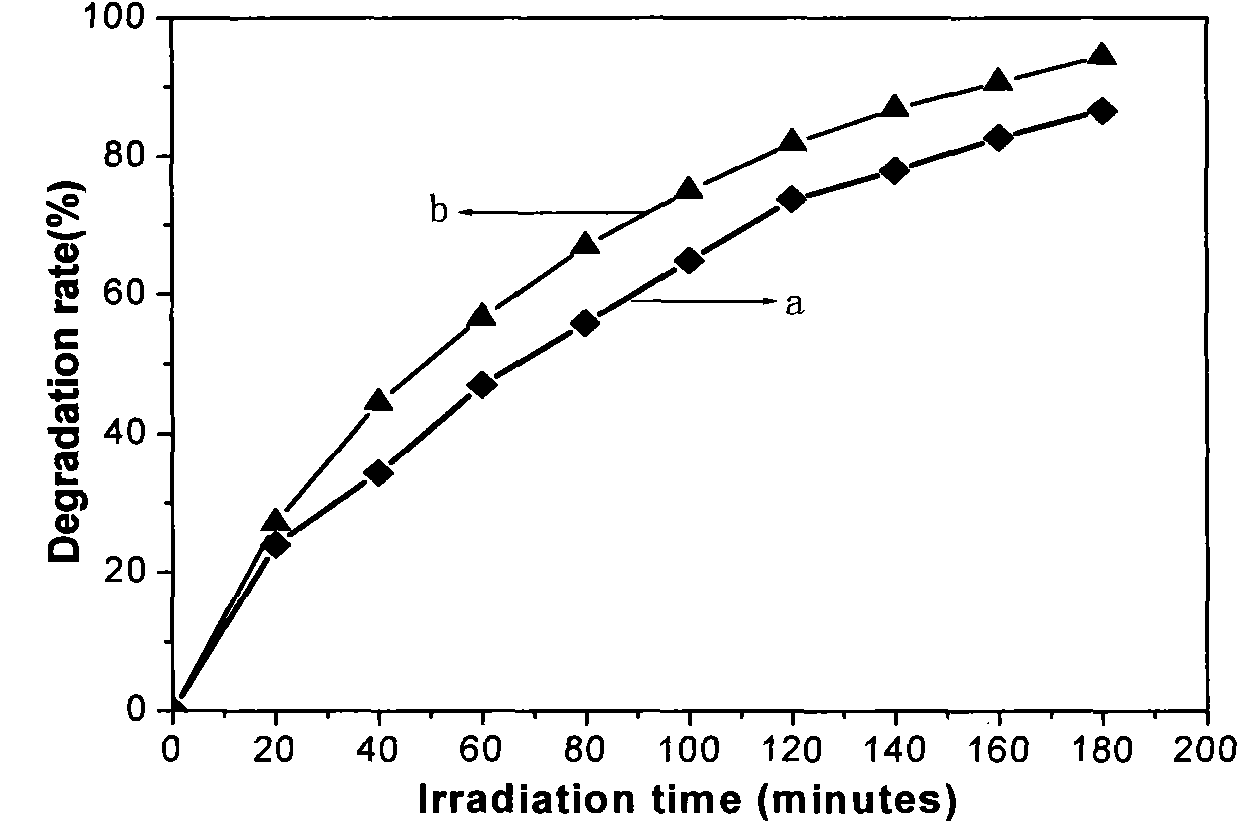

[0017] Using pure titanium sheet (99.6%) as the starting material, it is mechanically polished, chemically polished, and ultrasonically cleaned in sequence as the anode, high-purity graphite sheet as the cathode, and 0.5wt% HF aqueous solution as the electrolyte. The constant pressure oxidation condition is: 20V, 30min , 10±2°C; heat treatment conditions: 500°C, 120min. TiO prepared under this condition 2 The nanotube array is the photoelectrode, the high-purity graphite is the counter electrode, and the hexavalent chromium ion can be completely degraded by the method of the invention in about 3 hours.

example 2

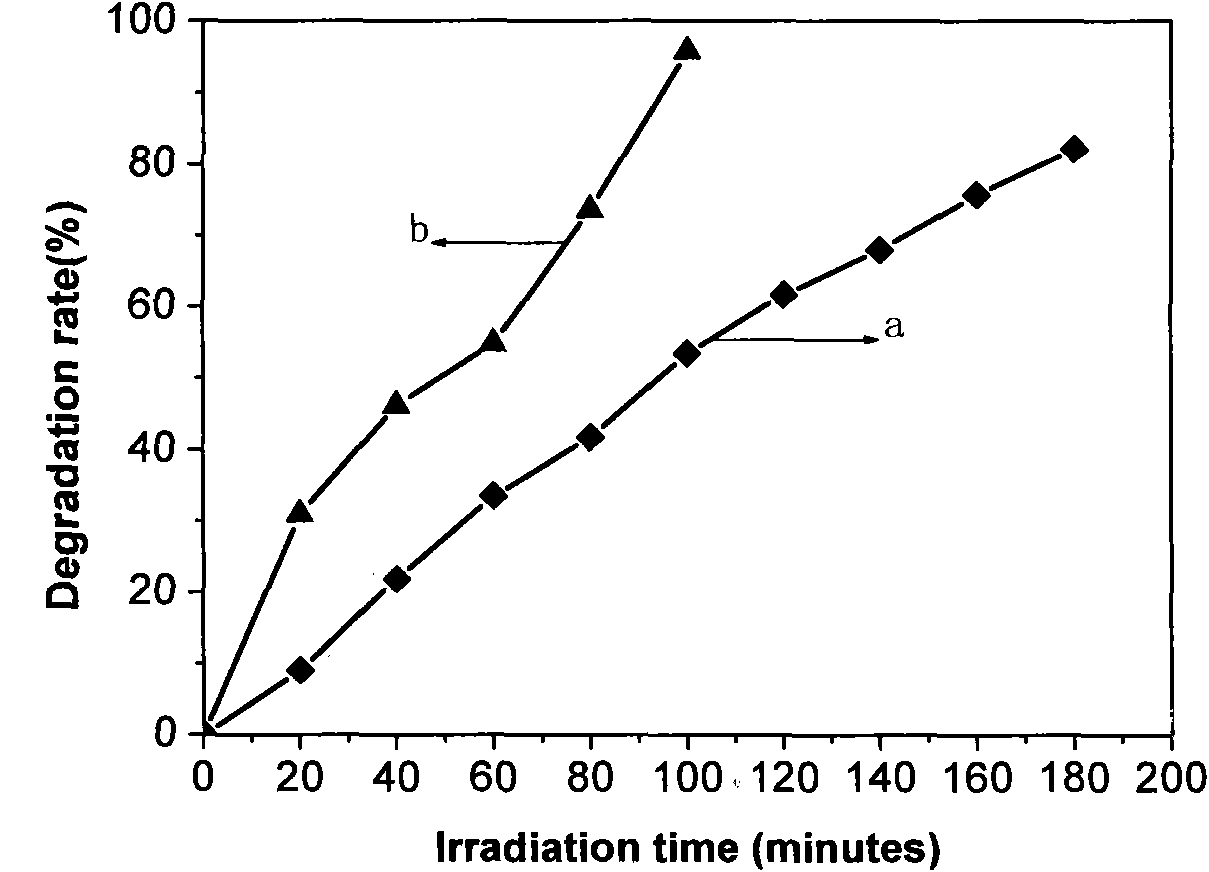

[0019] Using pure titanium sheet (99.6%) as the starting material, after mechanical grinding, chemical polishing, and ultrasonic cleaning, it is used as the anode, and high-purity graphite sheet is used as the cathode, 0.2wt% HF + 0.3wt% NH 4 F+C 3 h 8 o 3 The organic solution is the electrolyte, and the constant pressure oxidation condition is: 50V, 6h, 10±2°C; the heat treatment condition: 500°C, 120min. TiO prepared under this condition 2 The nanotube array is the photoelectrode, the high-purity graphite is the counter electrode, and 0.05M Na is added 2 SO 4 , the results of photoelectrocatalytic treatment of ammonia nitrogen wastewater are shown in image 3 , Test conditions: bias +1.0V, temperature 30±5°C, air flow 250ml / min (for 200ml solution), N initial concentration 100mg / L, pH=11 (adjusted with 10% NaOH solution). From image 3 It can be seen that under the condition of photoelectric catalysis and simultaneous stripping, the method of the present invention als...

example 3

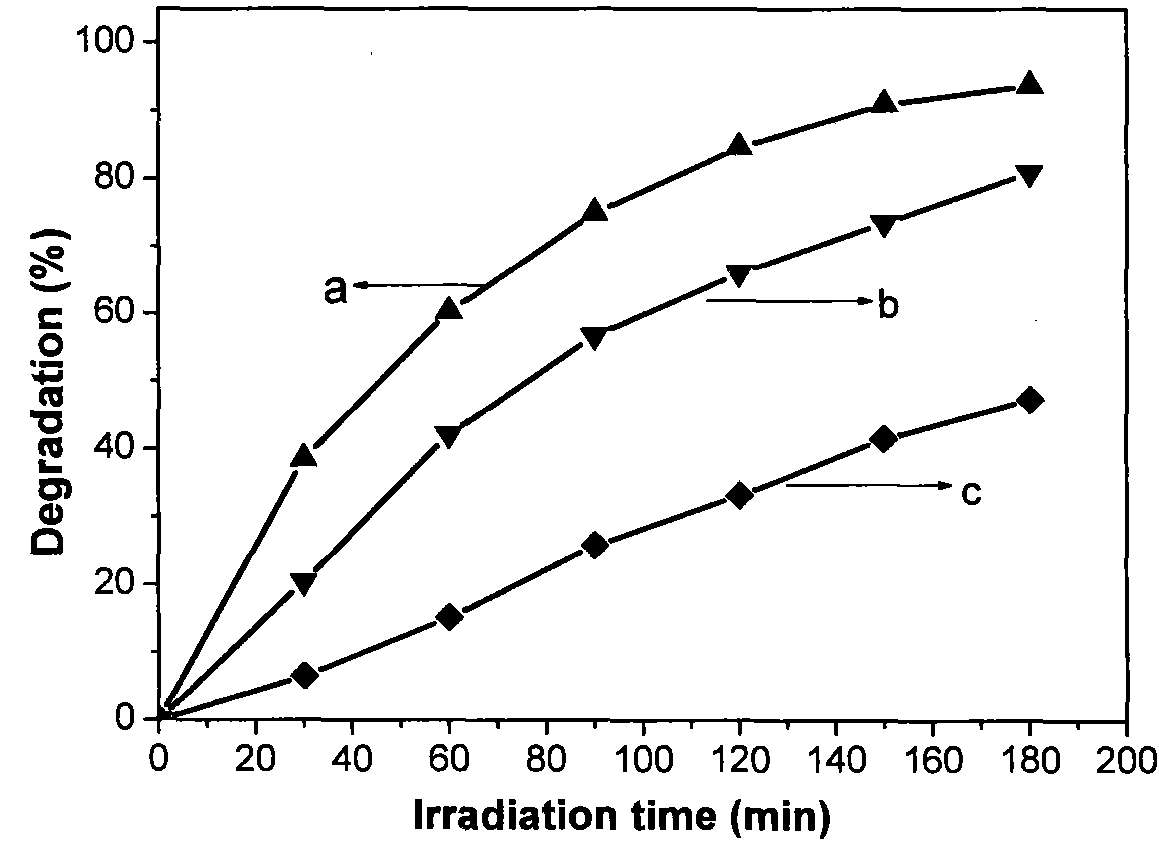

[0021] Using pure titanium sheet (99.6%) as the starting material, after mechanical grinding, chemical polishing, and ultrasonic cleaning, it is used as the anode, and high-purity graphite sheet is used as the cathode, 0.2wt% HF + 0.3wt% NH 4 F+C 3 h 8 o 3 The organic solution is the electrolyte, and the constant pressure oxidation condition is: 50V, 6h, 10±2°C; the heat treatment condition: 500°C, 120min. TiO prepared under this condition 2 The nanotube array is used as the photoelectrode, and the high-purity graphite is used as the counter electrode. The experimental results of the photoelectrocatalytic treatment of the composite wastewater of methylene blue and hexavalent chromium ions are shown in Figure 4 . Obviously, for the hexavalent chromium ion, it can be completely degraded in about 40 minutes by the method of the present invention. For methylene blue, the 2h degradation rate can reach 76.49%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com