Dyeing and printing waste clearing, synthetic wastewater advanced treatment circulation production and recycle technique

A comprehensive wastewater and advanced treatment technology, applied in the direction of water/sewage multi-stage treatment, flotation water/sewage treatment, oxidized water/sewage treatment, etc. High requirements and other issues, to achieve the effect of increasing infrastructure and maintenance costs, improving ozone utilization rate, and good denitrification function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

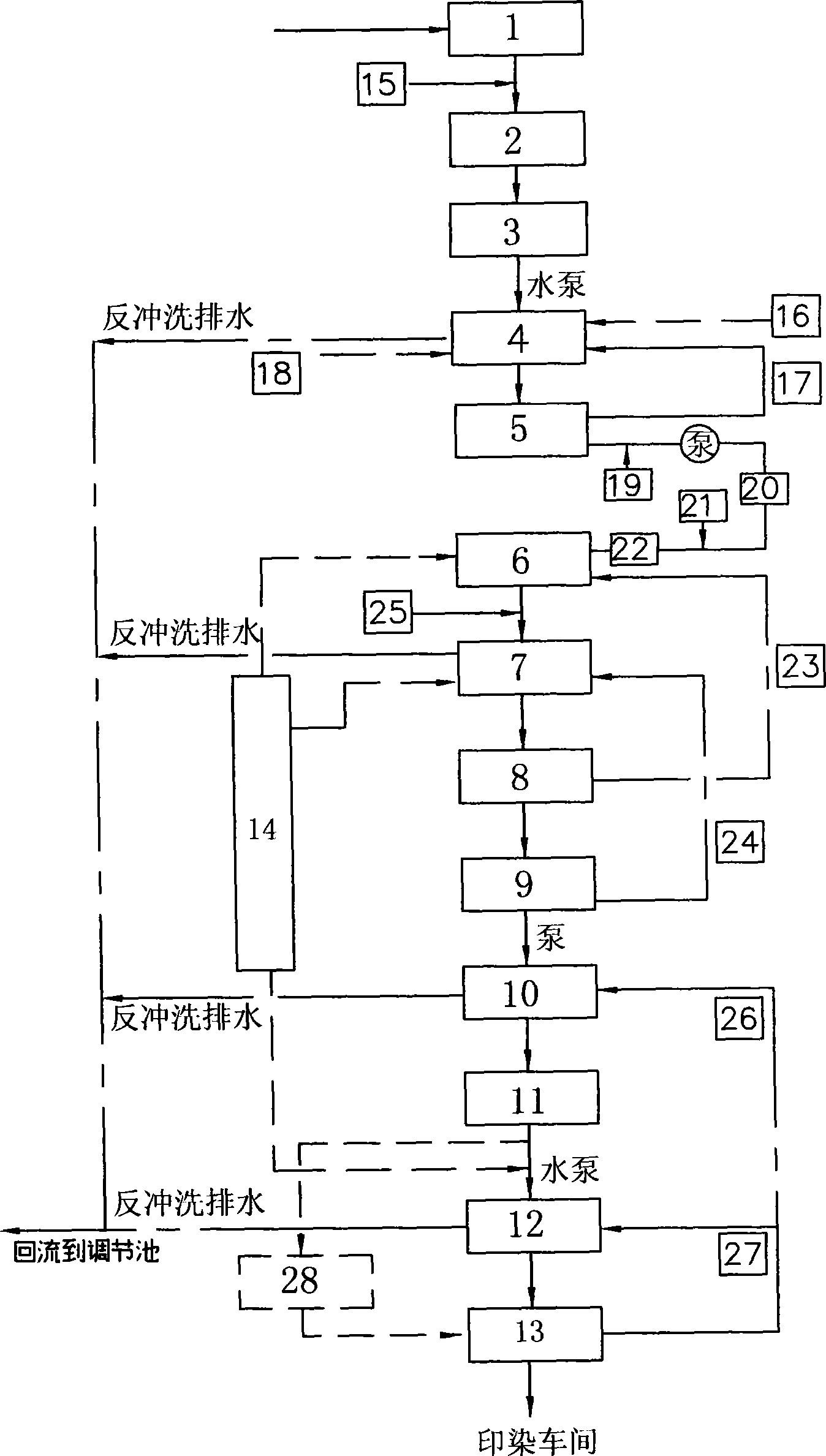

[0029] The present invention will be further described below in conjunction with accompanying drawings and examples of implementation.

[0030]As shown in the attached figure, the waste water discharged after cleaning and diversion or the comprehensive printing and dyeing waste water that meets the second-level discharge standard of the Discharge Standard of Water Pollutants for Textile Dyeing and Finishing Industry (GB4287-92) is collected by the pipe network and passes through the grid. 1 and fiber concentrator 2 remove the large suspended solids and long fibers in the wastewater, and then flow into the regulating tank 3 by itself. At the same time, according to the different properties of printing and dyeing wastewater, the structure of the regulating tank can be changed to make it have both hydrolysis and acidification, so as to improve the quality of wastewater. Biodegradability, reducing the processing load of the subsequent aerobic process. There is a mechanical agitato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com