Packaging stage-type film bioreactor device for treating sewage or micro-polluted raw water

A membrane bioreactor, micro-pollution technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., to achieve the effect of convenient use and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

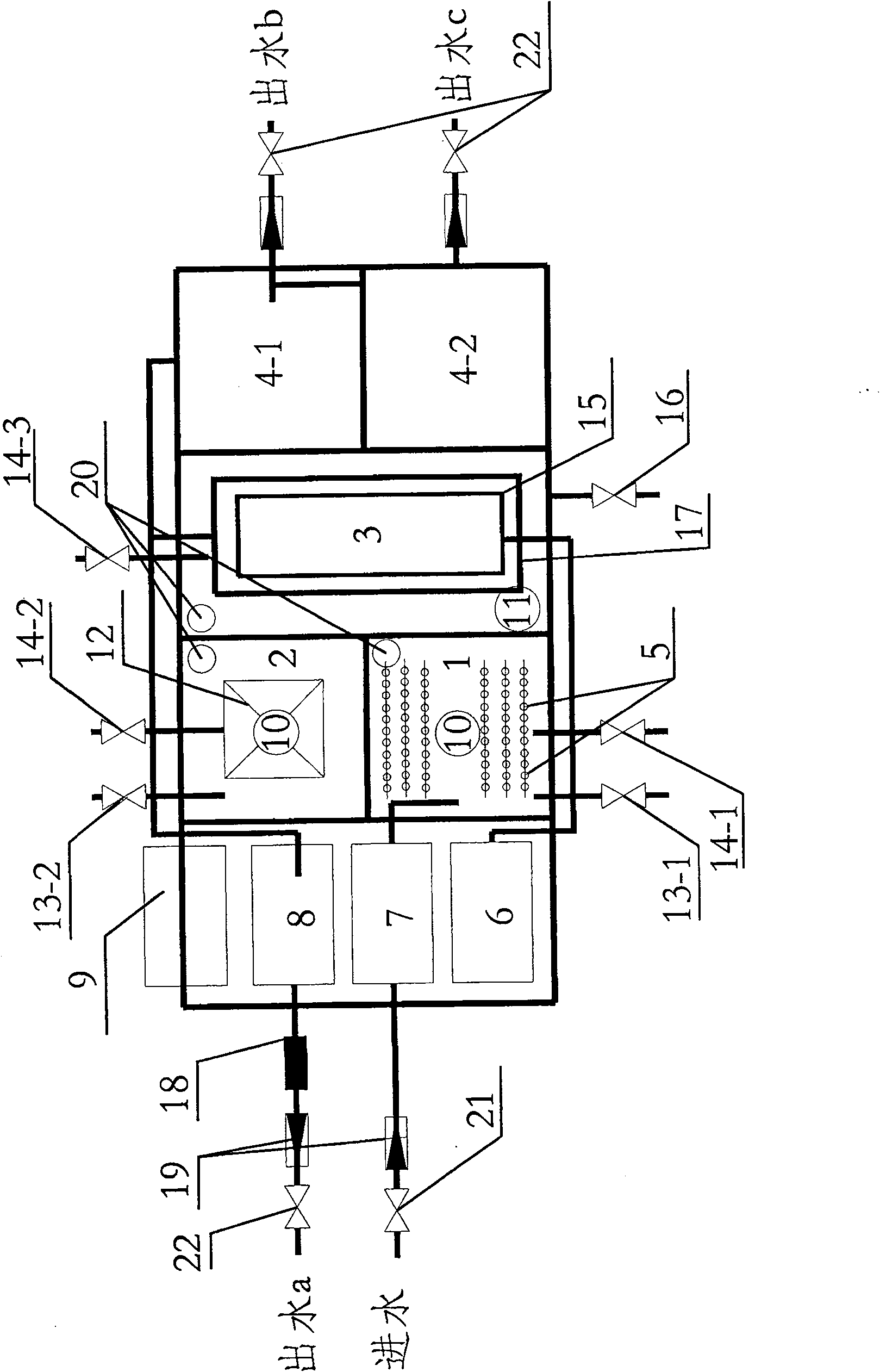

[0048] The container-type staged membrane bioreactor device is in the structure of a container body, which is sequentially composed of a semi-reaction zone 1, anaerobic reaction zone 2, aeration reaction zone 3, pure water zone 4-1, and pure water zone 4-2 (the other structured as figure 1 As shown), except that the reaction zones are separated by partitions, the pure water zone is not connected to the bottom of the anaerobic zone, but the semi-reaction zone is connected to the bottom of the aeration zone, which has the function of separating and defining each functional zone.

[0049] The water inlet system is composed of filler 5, water inlet pump 7, mixer 10, vent valve 14-1, flow meter 19 and water inlet valve 21. The water inlet is sucked by the water inlet pump 7 located on the side of the half-reaction area to the half-reaction area 1; the water inlet valve 21 is connected to the water inlet pump 7 through the flow meter 19 to control the flow rate; the filler 5 is loca...

Embodiment 2

[0058] The container-type staged membrane bioreactor device is a container body structure, which is composed of a half reaction zone 1, anaerobic reaction zone 2, and aerated reaction zone 3 (its structure is as follows: figure 1 shown), the reaction zones are separated by partitions, and the half-reaction zone is connected to the bottom of the aeration zone.

[0059] The water inlet system is composed of filler 5, water inlet pump 7, mixer 10, vent valve 14-1, flow meter 19 and water inlet valve 21. The water inlet is sucked by the water inlet pump 7 located on the side of the half-reaction area to the half-reaction area 1; the water inlet valve 21 is connected to the water inlet pump 7 through the flow meter 19 to control the flow rate; the filler 5 is located in the semi-reaction zone 1, with a ring arrangement as the main body, and is mainly used to strengthen the denitrification and hydrolysis functions of the semi-reaction zone The mixer 10 is located at the top of the s...

Embodiment 3

[0068] The container-type staged membrane bioreactor device is a container body structure, which is composed of a flocculation tank 1, a sedimentation tank 2, a reaction tank 3, a pure water area 4-1, and a pure water area 4-2 (its structure is as follows: figure 1 As shown), each reaction zone is separated by a partition, and the pure water zone is not connected to the bottom of other zones, which has the function of separating and defining each functional zone.

[0069] The water inlet system is composed of water inlet pump 7, mixer 10, dosing port 13-1, vent valve 14-1, flow meter 19 and water inlet valve 21. In the flocculation tank 1; the water inlet valve 21 is connected to the water inlet pump 7 through the flow meter 19 to control the flow rate; at the same time, the dosing port 13-1 is enabled to add the flocculation agent, and the mixer 10 is located at the top of the half reaction zone 1 to promote the flow of the agent. Dissolving and flocculation net capture; if m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com