Preparation for general defoaming agent and its application

A defoamer and defoaming technology, applied in the directions of foam dispersion/prevention, dissolution, chemical instruments and methods, etc., can solve the problem of affecting product quality, affecting phosphating and spraying processes, and the defoaming and suppressing performance of non-organic silicon defoamer problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

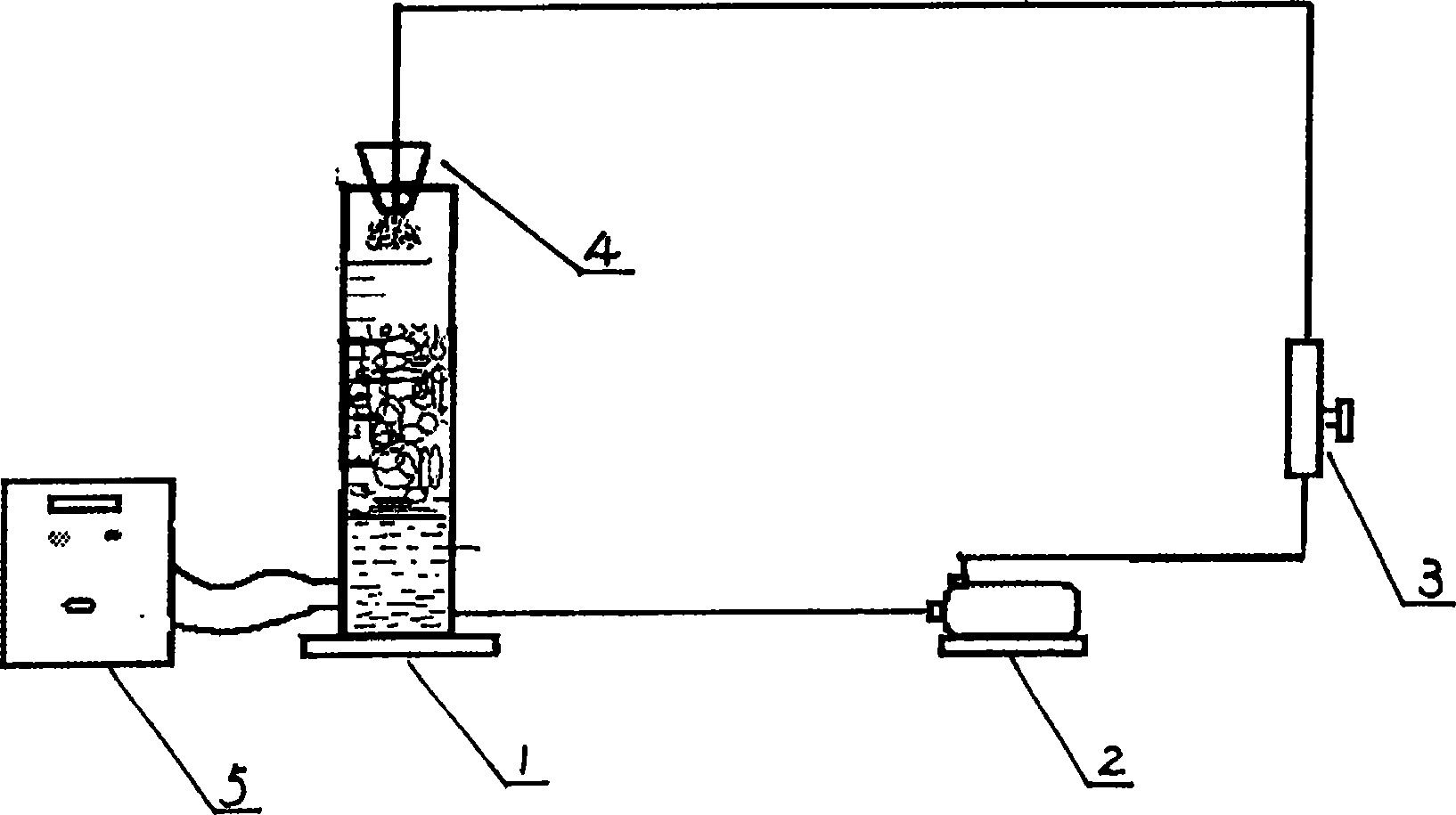

Image

Examples

Embodiment 1

[0039] Add 53 parts of liquid wax with a viscosity of 40 mPas and 4 parts of aluminum stearate into the reaction bottle, start stirring, and slowly raise the temperature. After the temperature rises to 135-140° C., keep the temperature for 2 hours. After the heat preservation is completed, add 30 parts of alkylbenzene to it, lower the temperature to 90°C, then add 3 parts of hydrophobic white carbon black and 7 parts of defoaming synergist (R 1 =CH 3 (CH 2 ) 17 -, R 2 =CH 3 (CH 2 ) 10 CO-, x=20, y=50), and kept at 85-90°C for 1h. After the heat preservation is over, lower the temperature to around 50°C, add 3 parts of nonylphenol polyoxyethylene ether (7) emulsifier, and mix well to obtain defoamer A.

Embodiment 2

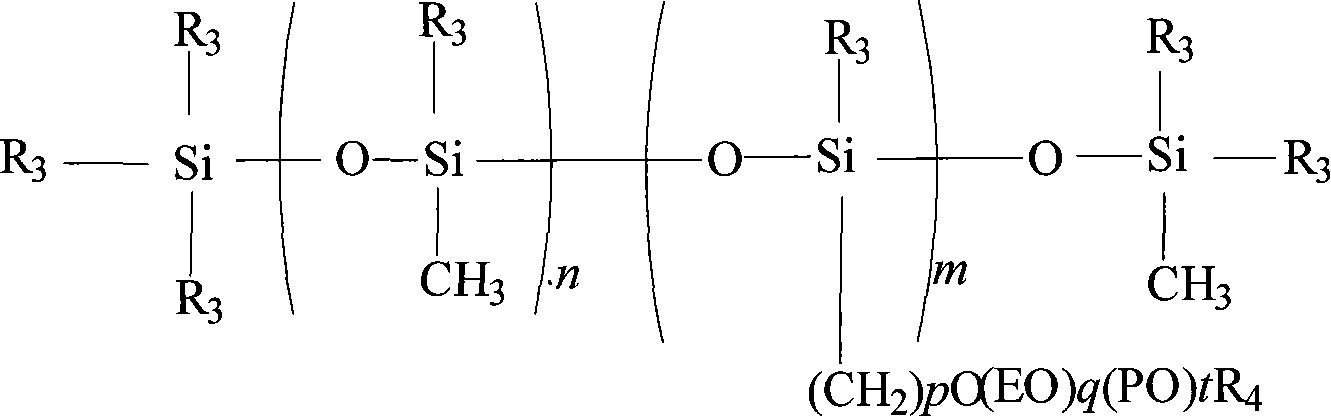

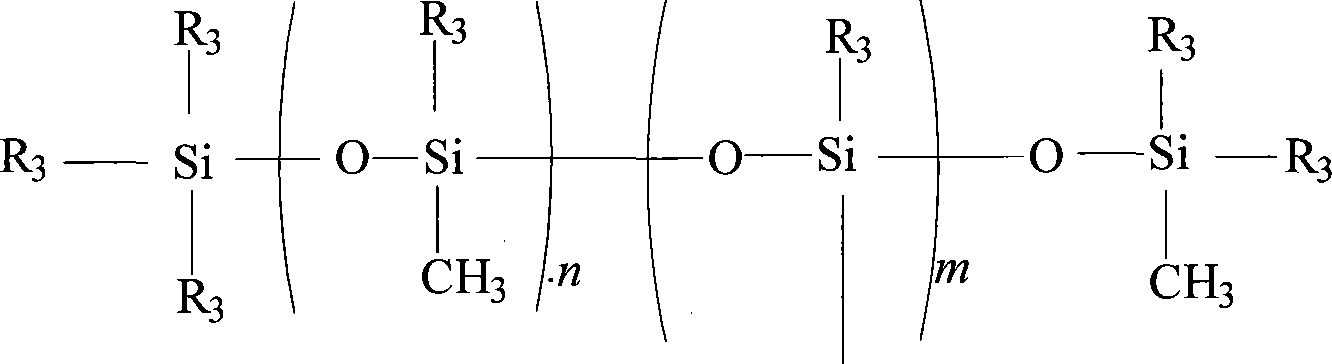

[0043] Add 41 parts of alkylbenzene, 2 parts of aluminum stearate and 3 parts of EBS into the reaction flask, start stirring, and slowly raise the temperature. After the temperature rises to 135-140°C, keep it warm for 1 hour. After the heat preservation is completed, add 40 parts of butter to it, when the temperature drops to around 80°C, add 4 parts of hydrophobic white carbon black and 5 parts of defoaming synergist (R 3 =-CH 3 , R 4 =H, p=3, q=5, t=6, m=20, n=70), and kept at 75-85°C for 1h. After the heat preservation is over, when the temperature drops to around 50°C, add 5 parts of oleic acid polyoxyethylene ether (6) and mix evenly to obtain defoamer B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com