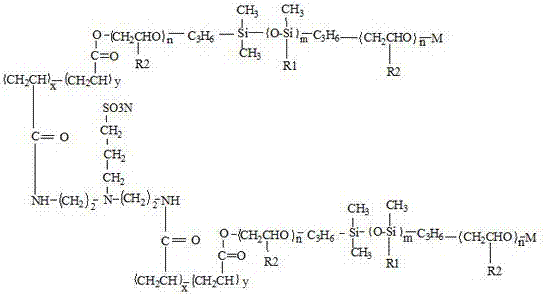

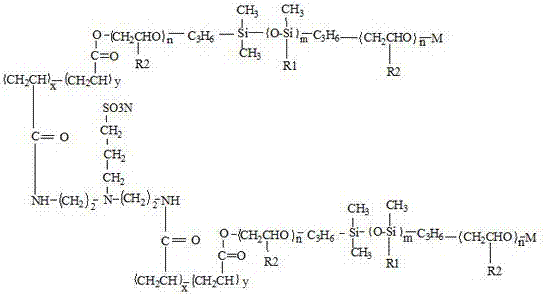

Gemini organic silicon defoamer

An organosilicon defoamer and twin-type technology, applied in the direction of foam dispersion/prevention, etc., can solve the problem of inability to adapt to the foaming system, and achieve the effect of good foam suppression performance, good foam suppression effect and good defoaming activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

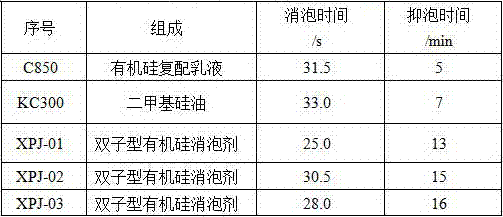

Examples

Embodiment 1

[0022] The preparation method of described gemini type organosilicon defoamer, comprises the following steps:

[0023] .Add 1.5g of sodium hydroxide into the autoclave, then add 58g of initiator propylene alcohol, and quickly press the lid of the autoclave. Vacuum at room temperature to make the reaction initial pressure reach -0.1 MPa. Mix 396g EO and 168g PO in the storage tank, press in about 50 g of EO / PO through the storage tank, turn on the stirring and heating device, and raise the temperature to react. After the reaction is stable, the remaining EO / PO is added in batches, 30-40 g each time, and the reaction temperature is maintained at about 115°C. After the reaction was complete, the temperature was lowered to 105°C. After the feeding is completed, the aging reaction is carried out until the pressure in the kettle returns to -0.1 MPa, and the allyl alcohol polyether is obtained by cooling and discharging.

[0024] Put 100g of low-hydrogen silicone oil UC11 and 96g ...

Embodiment 2

[0029] The preparation method of described gemini type organosilicon defoamer, comprises the following steps:

[0030] a. Add 1.5g of sodium hydroxide into the autoclave, then add 58g of initiator propylene alcohol, and quickly press the lid of the autoclave. Vacuum at room temperature to make the reaction initial pressure reach -0.1 MPa. Press in about 80 g of EO through the ethylene oxide (EO) storage tank, turn on the stirring and heating device, and heat up the reaction. After the reaction is stable, add the remaining EO in batches, 40-50 g each time, the total amount added is 308 g, and the reaction temperature is maintained at 110-125 °C. After the EO reaction is complete, lower the temperature to 105-110 °C. After the feeding is completed, the aging reaction is carried out until the pressure in the kettle returns to -0.1 MPa, and the allyl alcohol polyether is obtained by cooling and discharging.

[0031]Put 100g of low-hydrogen silicone oil uc12 and 88g of the above...

Embodiment 3

[0036] The preparation method of described gemini type organosilicon defoamer, comprises the following steps:

[0037] a. Add 1.5g of sodium hydroxide into the autoclave, then add 58g of initiator propylene alcohol, and quickly press the lid of the autoclave. Vacuum at room temperature to make the reaction initial pressure reach -0.1 MPa. Mix 396g of EO and 168g of PO in the storage tank, press in about 50g of EO / PO through the storage tank, turn on the stirring and heating device, and raise the temperature to react. After the reaction is stable, the remaining EO / PO is added in batches, 30-40 g each time, and the reaction temperature is maintained at about 115°C. After the reaction was complete, the temperature was lowered to 105°C. After the feeding is completed, the aging reaction is carried out until the pressure in the kettle returns to -0.1 MPa, and the allyl alcohol polyether is obtained by cooling and discharging.

[0038] b. Vacuum distill 100g of low-hydrogen silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com