Solid particle foam inhibitor and method for preparing same

A technology of solid particles and anti-foaming agent, applied in the direction of foam dispersion/prevention, etc., can solve the problems of inability to function, products easily hardened, and prone to decay, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] 1. Preparation of main defoaming substances

[0030] The high-viscosity silicone grease was prepared according to the methods of Example 1 and Example 2 of patent CN200610040821.3, and the obtained defoaming active substances were X1 and X2 respectively.

[0031] Low-viscosity polyorganosiloxanes are hydroxyl-terminated polydimethylsiloxanes with kinematic viscosities of 100 mPa·s, 10,000 mPa·s, and 20,000 mPa·s at 25°C, respectively, and are denoted as B1, B2, and B3.

[0032] 2, preparation embodiment solid particle antifoaming agent

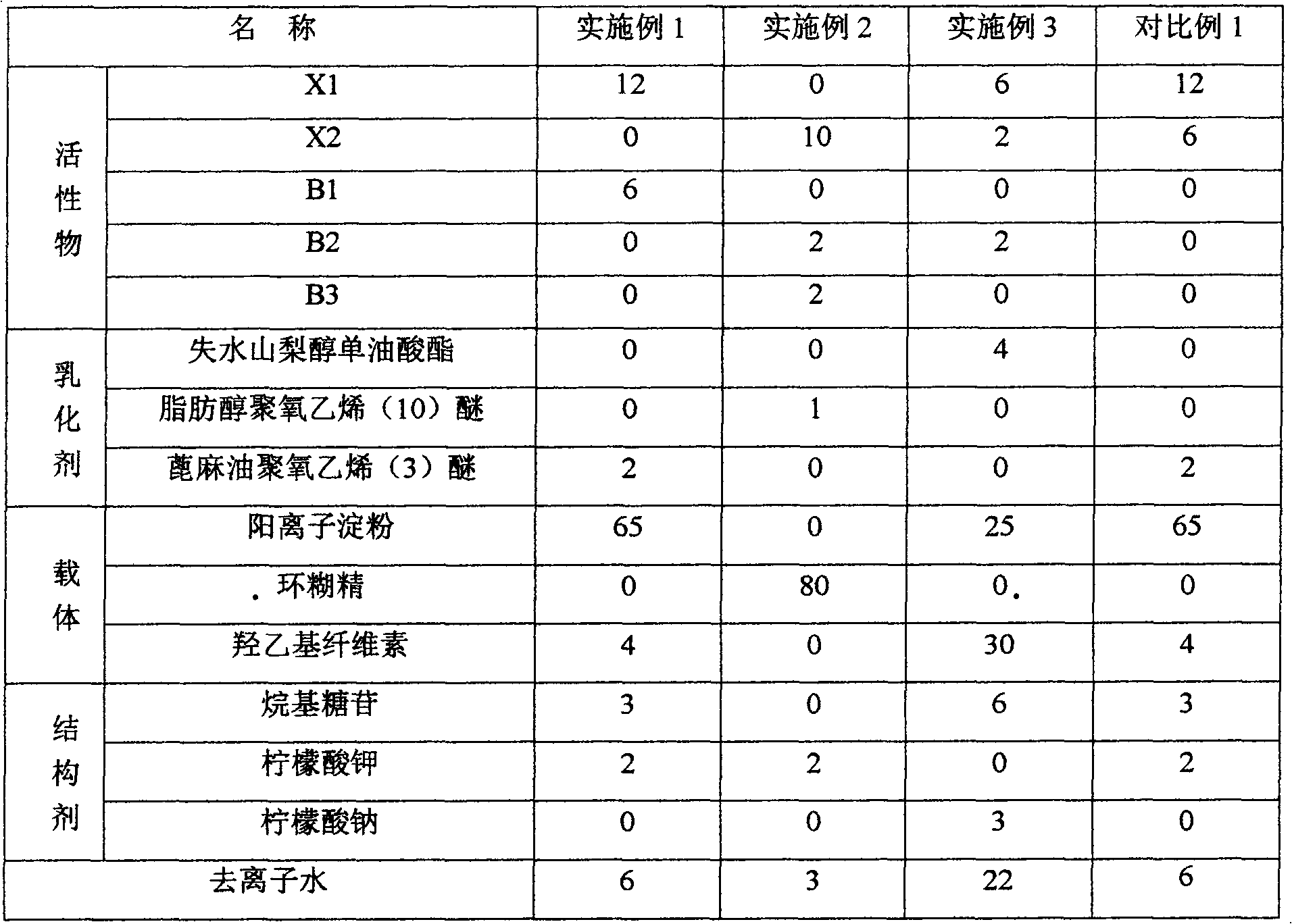

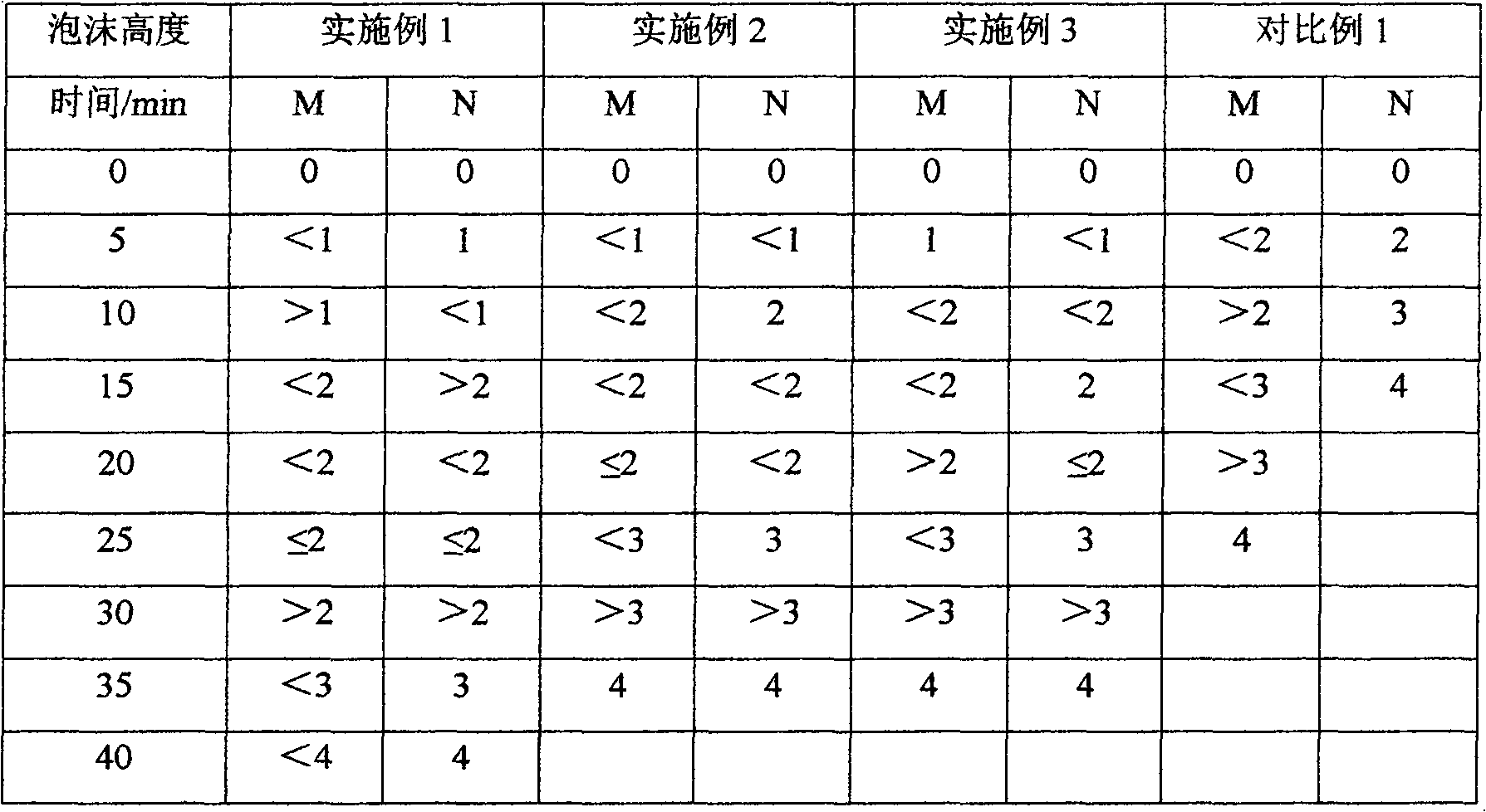

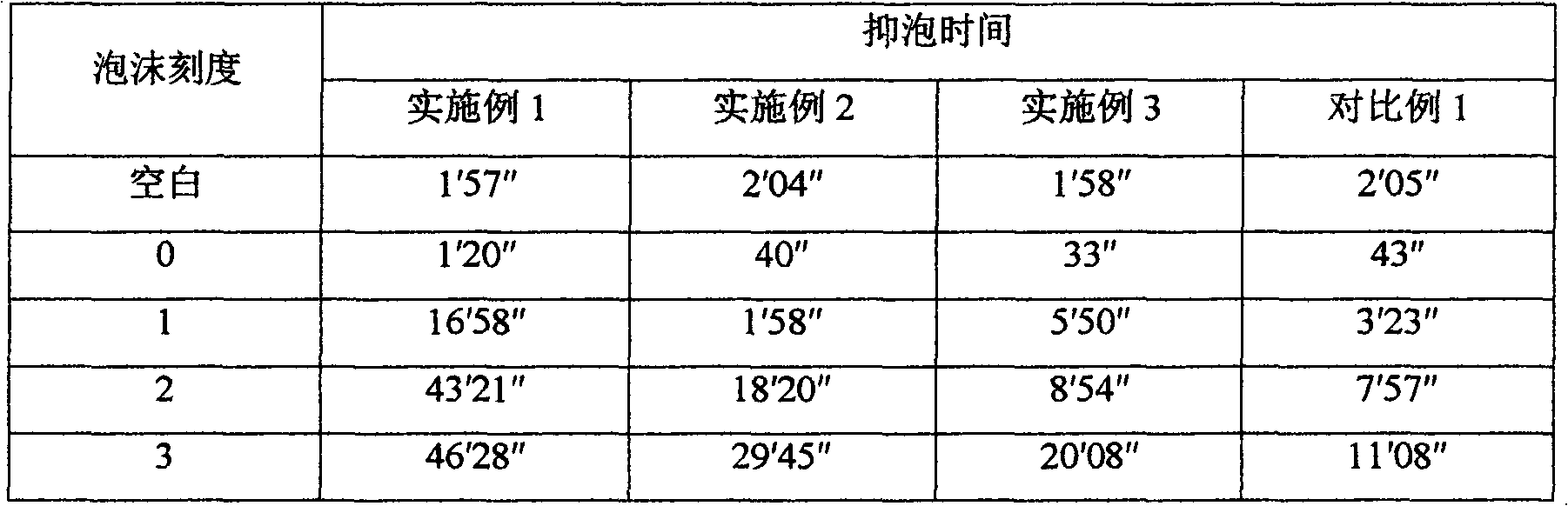

[0033] The ratio between each constituent material of specific embodiment sees the following table:

[0034] Table 1 The proportion (mass percentage, %) that each component of solid particle antifoaming agent accounts for

[0035]

[0036] Each component in the above table was prepared respectively according to the aforementioned preparation method of the present invention as solid particle foam suppressor Example 1, Example 2, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com